Enterprise News

LATEST NEWS

The use of automatic cake dispenser can improve the shelf life of the cake.

2022-10-08

The automatic cake dispenser integrates pre-mixing, storage and conveying, and can fully mix and convey the batter. Can be used for all cake products, such as lasagna, mini rolls, cupcakes, muffin cakes, cookies, egg cakes, mousse, cream, etc.

View in detail.Cake automatic sending machine to improve efficiency

2022-09-13

A set of automatic cake dispenser is designed for small and medium-sized factories, including pre-mixing cylinder, storage cylinder, automatic inflator, homogenizer and filling machine. The cake automatic sending machine can reduce labor costs, reduce waste of materials and materials, improve production efficiency, and stabilize product quality.

View in detail.Overview of the production process of cake hair machine

2022-08-31

The output of the cake mixer is designed according to the customer's requirements, and also depends on the formula and proportion of the product. Can be used for all cake products, such as lasagna, mini rolls, cupcakes, muffin cakes, cookies, egg cakes, mousse, cream, etc.

View in detail.Introduction to the composition of aerated chocolate

2022-08-23

Aerated chocolate is a shelf-stable confectionery product having a chocolate core and a sugar-based outer shell coating, characterized in that air bubbles having an average diameter of less than 25 microns are dispersed in the chocolate core. In the production of aerated chocolate, the aeration temperature and time should be controlled to make the cocoa butter in the rapid crystallization stage.

View in detail.Gas mass flow control during aeration of aerated chocolate

2022-08-02

Due to the unique taste of aerated chocolate is becoming more and more popular. So how is aerated chocolate generally aerated? The process involves high performance mass flow control. When high-pressure gas is injected into the liquid chocolate to expand, bubbles are formed. The gas used is typically N2 or carbon dioxide. After the gas is injected, the liquid chocolate with the temperature change is moved into the mold, and then the pressure is reduced to allow the chocolate to cool. By adjusting the gas volume, the bubble size of the chocolate can be controlled, and reducing the pressure helps this process. As the chocolate cools, it solidifies, solidifying the bubbles in the chocolate matrix.

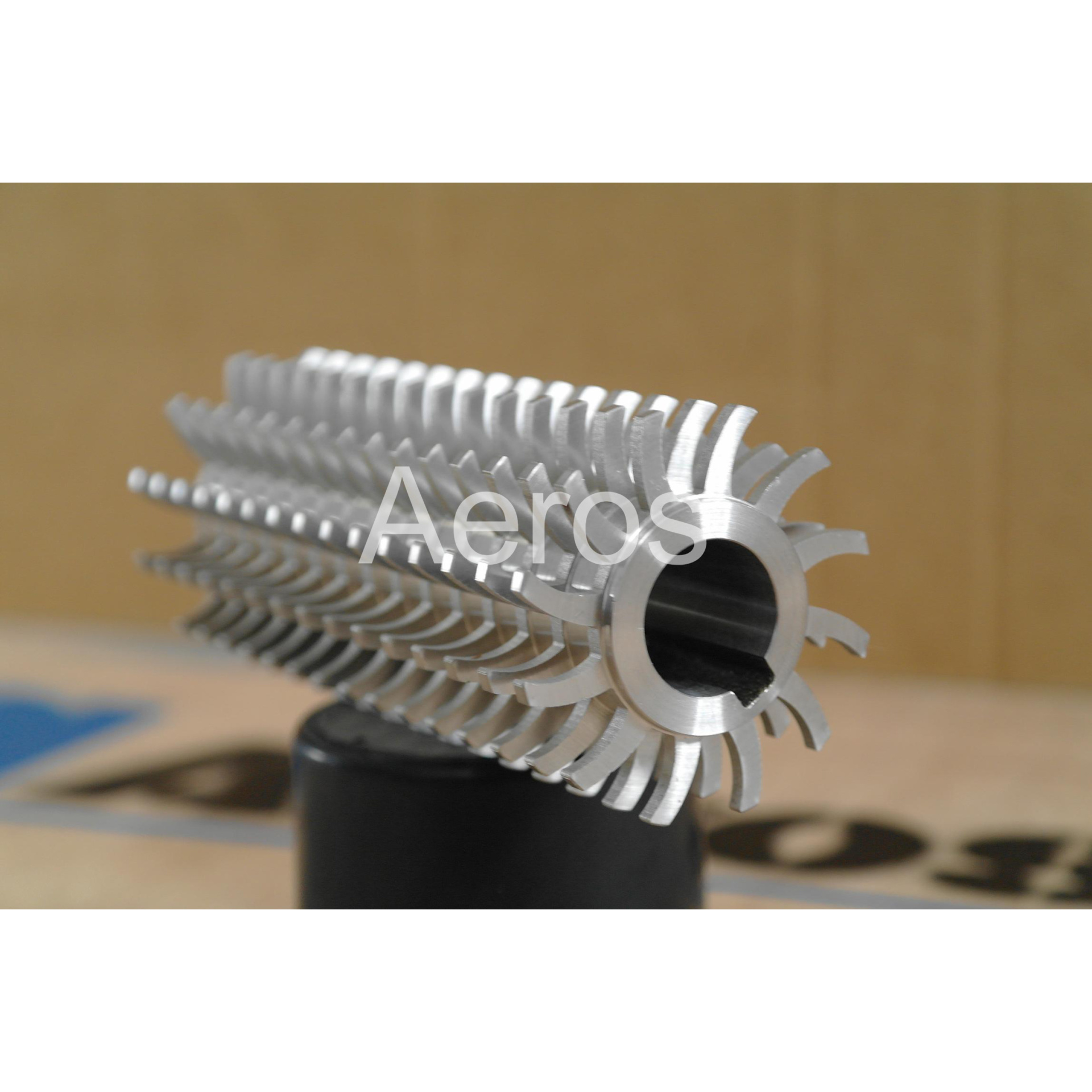

View in detail.Structure of latex chemical foaming machine

2022-07-15

Latex chemical foaming machine is an important mechanical equipment in latex machinery. The latex chemical foaming machine is composed of foaming machine head, glue injection pump, motor, reducer, metering pump and electric control system. Latex chemical foaming machine is a professional equipment for the production of latex products. Natural latex collected from rubber tree, with ammonia preservation, mixing.

View in detail.How to adjust the density of latex foaming machine?

2022-07-05

Automatic latex foaming machine is an important mechanical equipment in latex machinery, and it is the core machinery in the production of latex products. It consists of a stainless steel housing, die head, rubber pump, motor and electrical system. How to adjust the density of the latex foaming machine? The density of the latex foaming machine can determine the hardness of the latex foaming machine product. This is mainly in response to customer requirements. Some people like hard latex mattresses, others like soft mattresses. The density adjustment of the latex foaming machine mainly depends on the ratio of the latex formula and the latex formula. For ordinary latex foaming machines, the foaming ratio is usually 10-15 times. Customers can design the density of the latex foaming machine according to the formula requirements.

View in detail.How to prevent cotton candy production line equipment failure frequently?

2022-06-06

The failure of the cotton candy production line machinery is what the manufacturer does not want to see. Failure means that the production line needs to be stopped and the equipment needs to be repaired. All of this has an impact on development. Only by avoiding failure can these developments be unrestricted and the development space of manufacturers will continue to increase. Marshmallow production line machinery how to reduce failure? The following details for you:

View in detail.Yalus Cake Inflation System Operation/Cleaning/Maintenance Guide

2022-05-16

Before starting the Yalus cake inflation system, check whether the circuit is virtual, whether the screws of terminals and electrical components are tightened, and whether the ground wire is protected and grounded. Check whether the pneumatic connection is correctly connected and whether the air pipe connector is tightly inserted.

View in detail.The working principle of the cake sending machine

2022-05-06

The cake dispenser uses technologies ranging from pre-mixing and storage to high-speed delivery. The whole cake sending machine system consists of premixing system, storage system, conveying system, sending system and control system. With such a continuous conveying system, the cake raw materials can be stirred and conveyed in a short time, and the conveyed cake raw materials will be automatically conveyed to the cake grouting machine through the automatic conveying pipe, so that the batter can have the same proportion from the beginning to the end of the product. The problem of rough and unstable product quality produced by the egg beater is overcome.

View in detail.