Everything You Need to Know About Marshmallow Machines: A Sweet Journey into Candy Manufacturing

2025/07/13

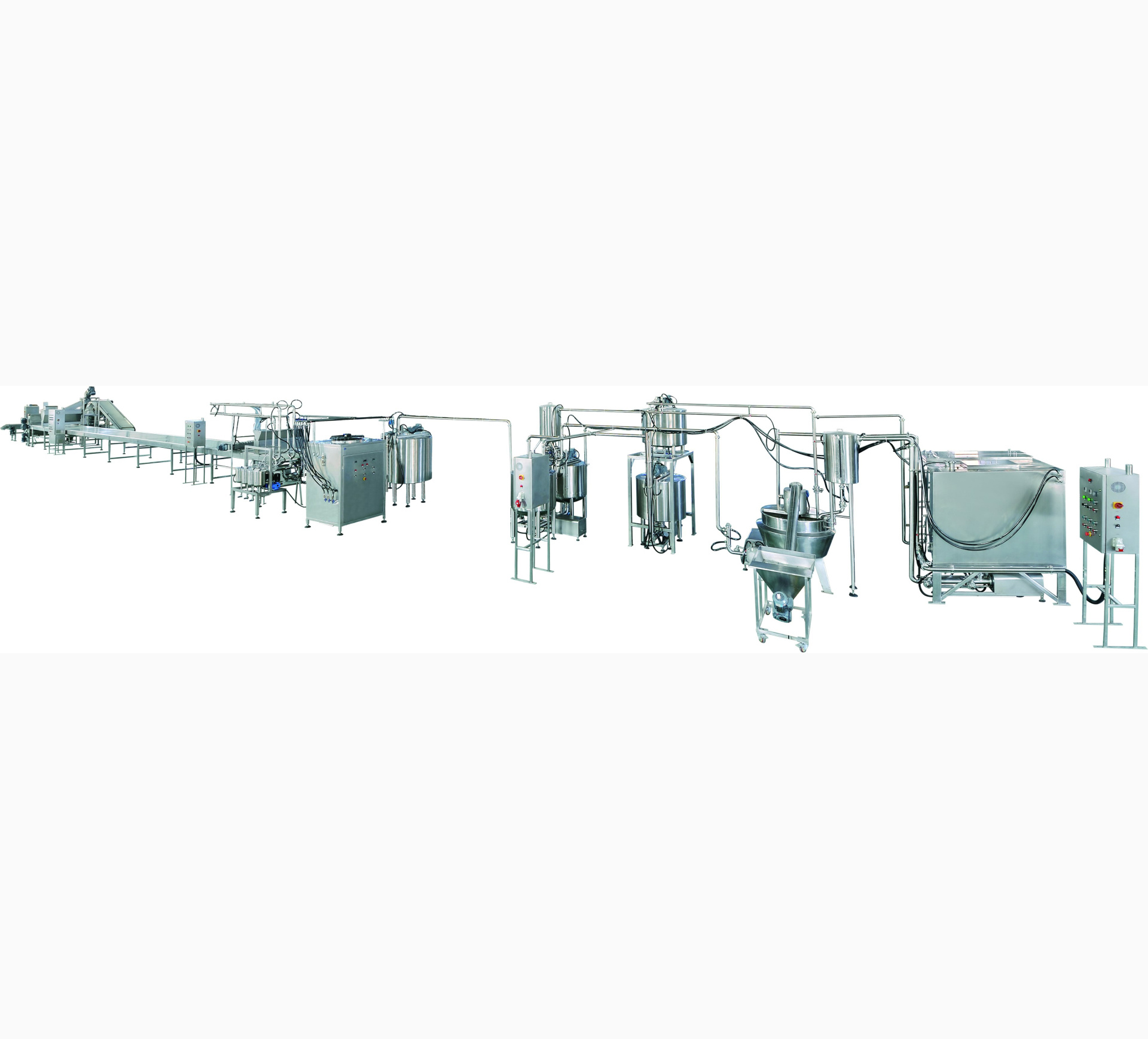

Marshmallow machines are specialized equipment designed to streamline the production of marshmallows, one of the most beloved confections. These machines cater to various stages of marshmallow production, from mixing ingredients to shaping and packaging the final product. Understanding how marshmallow machines work can provide valuable insights into the candy manufacturing process.

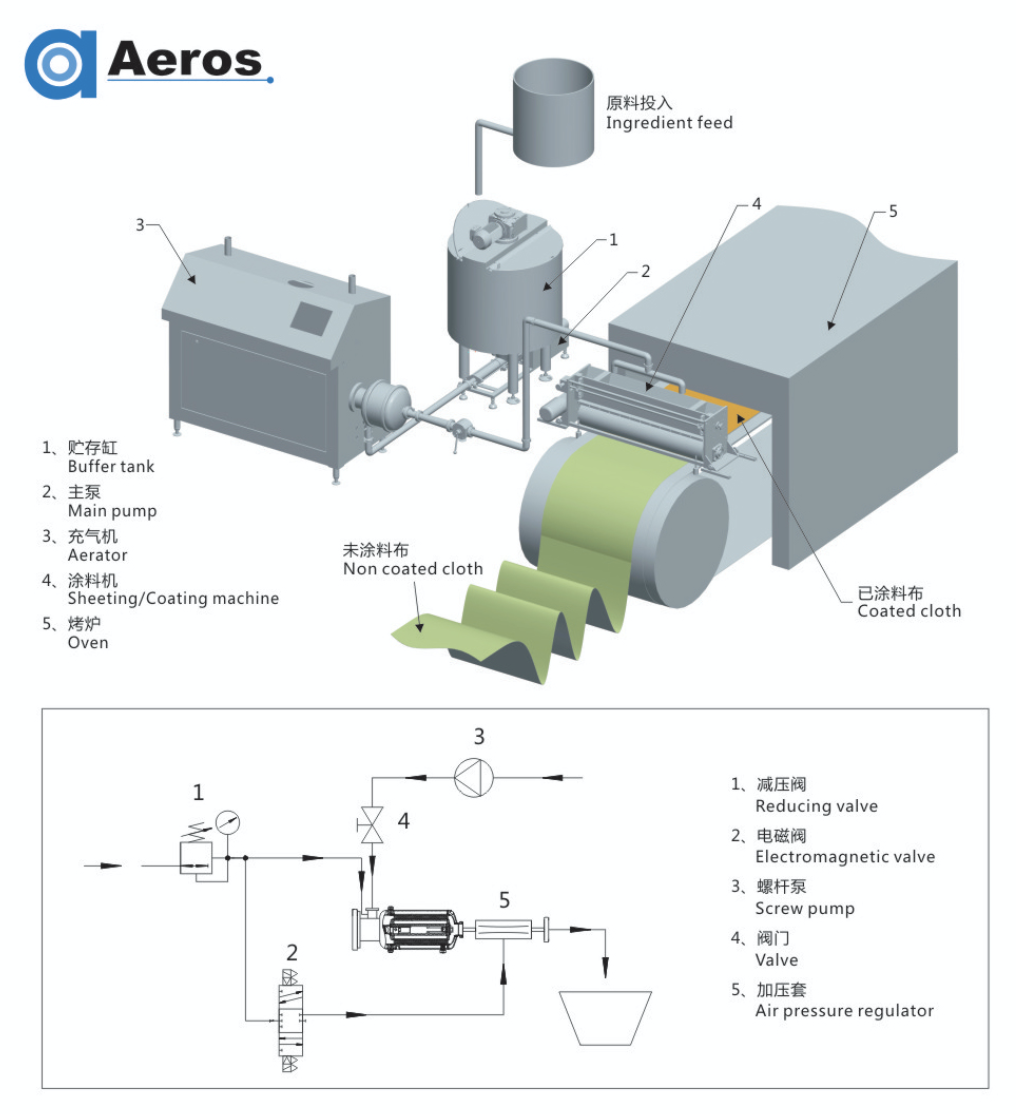

At the core of the marshmallow production process is the combination of sugar, corn syrup, water, and gelatin. These ingredients are heated and mixed together in a marshmallow machine to create a smooth, homogenous mixture. One critical aspect is the aeration process, where air is incorporated into the mixture to give marshmallows their characteristic light and fluffy texture. Some marshmallow machines feature advanced aeration systems that ensure optimal distribution of air bubbles, which is essential for achieving the perfect marshmallow consistency.

Another important feature of marshmallow machines is their ability to control temperature and humidity. The production environment greatly impacts the final product's quality. For instance, maintaining the right temperature ensures that the sugar mixture reaches the desired viscosity, while controlled humidity levels prevent premature crystallization. Modern marshmallow machines often come equipped with precise temperature control systems that allow manufacturers to achieve consistent results batch after batch.

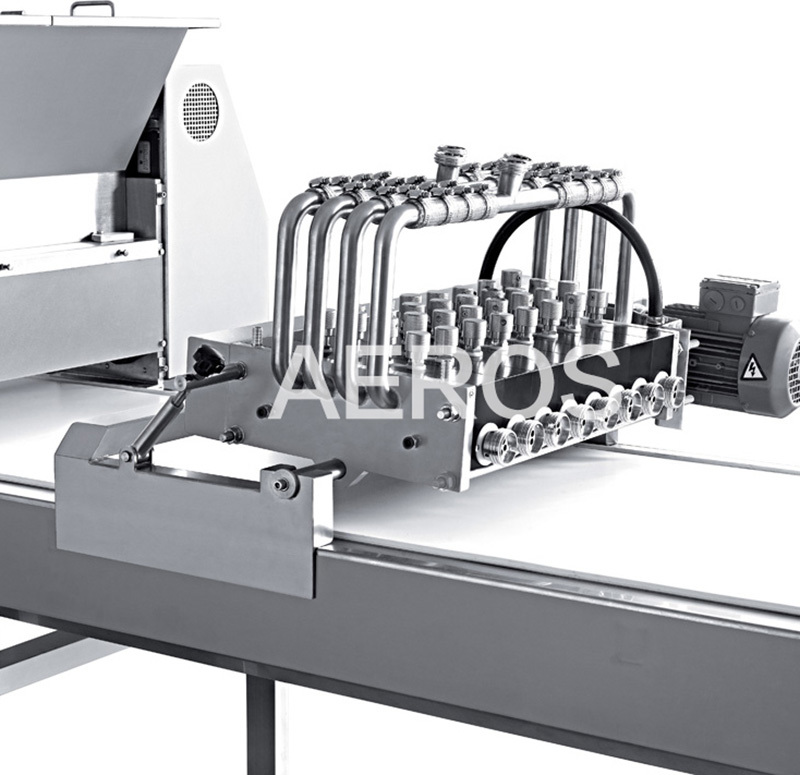

The shaping and cutting process is where marshmallows take form. Many marshmallow machines are designed with customizable molds and cutting mechanisms that allow manufacturers to produce various shapes and sizes. This flexibility enables candy producers to cater to diverse market demands, from traditional marshmallows to innovative products like marshmallow-filled chocolates.

Additionally, the packaging of marshmallows is crucial for preserving freshness and extending shelf life. Marshmallow machines can often be integrated with packaging systems that automatically wrap and seal the final product, ensuring it remains soft and tasty until it reaches the consumer.

In conclusion, marshmallow machines are vital tools in the candy manufacturing process, transforming simple ingredients into delightful treats. By understanding the operation and features of these machines, manufacturers can enhance production efficiency and product quality. Whether you're a seasoned professional in the food processing industry or a curious enthusiast, the intricacies of marshmallow machines provide a fascinating glimpse into the world of candy making.

At the core of the marshmallow production process is the combination of sugar, corn syrup, water, and gelatin. These ingredients are heated and mixed together in a marshmallow machine to create a smooth, homogenous mixture. One critical aspect is the aeration process, where air is incorporated into the mixture to give marshmallows their characteristic light and fluffy texture. Some marshmallow machines feature advanced aeration systems that ensure optimal distribution of air bubbles, which is essential for achieving the perfect marshmallow consistency.

Another important feature of marshmallow machines is their ability to control temperature and humidity. The production environment greatly impacts the final product's quality. For instance, maintaining the right temperature ensures that the sugar mixture reaches the desired viscosity, while controlled humidity levels prevent premature crystallization. Modern marshmallow machines often come equipped with precise temperature control systems that allow manufacturers to achieve consistent results batch after batch.

The shaping and cutting process is where marshmallows take form. Many marshmallow machines are designed with customizable molds and cutting mechanisms that allow manufacturers to produce various shapes and sizes. This flexibility enables candy producers to cater to diverse market demands, from traditional marshmallows to innovative products like marshmallow-filled chocolates.

Additionally, the packaging of marshmallows is crucial for preserving freshness and extending shelf life. Marshmallow machines can often be integrated with packaging systems that automatically wrap and seal the final product, ensuring it remains soft and tasty until it reaches the consumer.

In conclusion, marshmallow machines are vital tools in the candy manufacturing process, transforming simple ingredients into delightful treats. By understanding the operation and features of these machines, manufacturers can enhance production efficiency and product quality. Whether you're a seasoned professional in the food processing industry or a curious enthusiast, the intricacies of marshmallow machines provide a fascinating glimpse into the world of candy making.

Marshmallow machines

Previous Page