The Essential Guide to Chocolate Equipment: Enhancing Your Production Process

2025/07/11

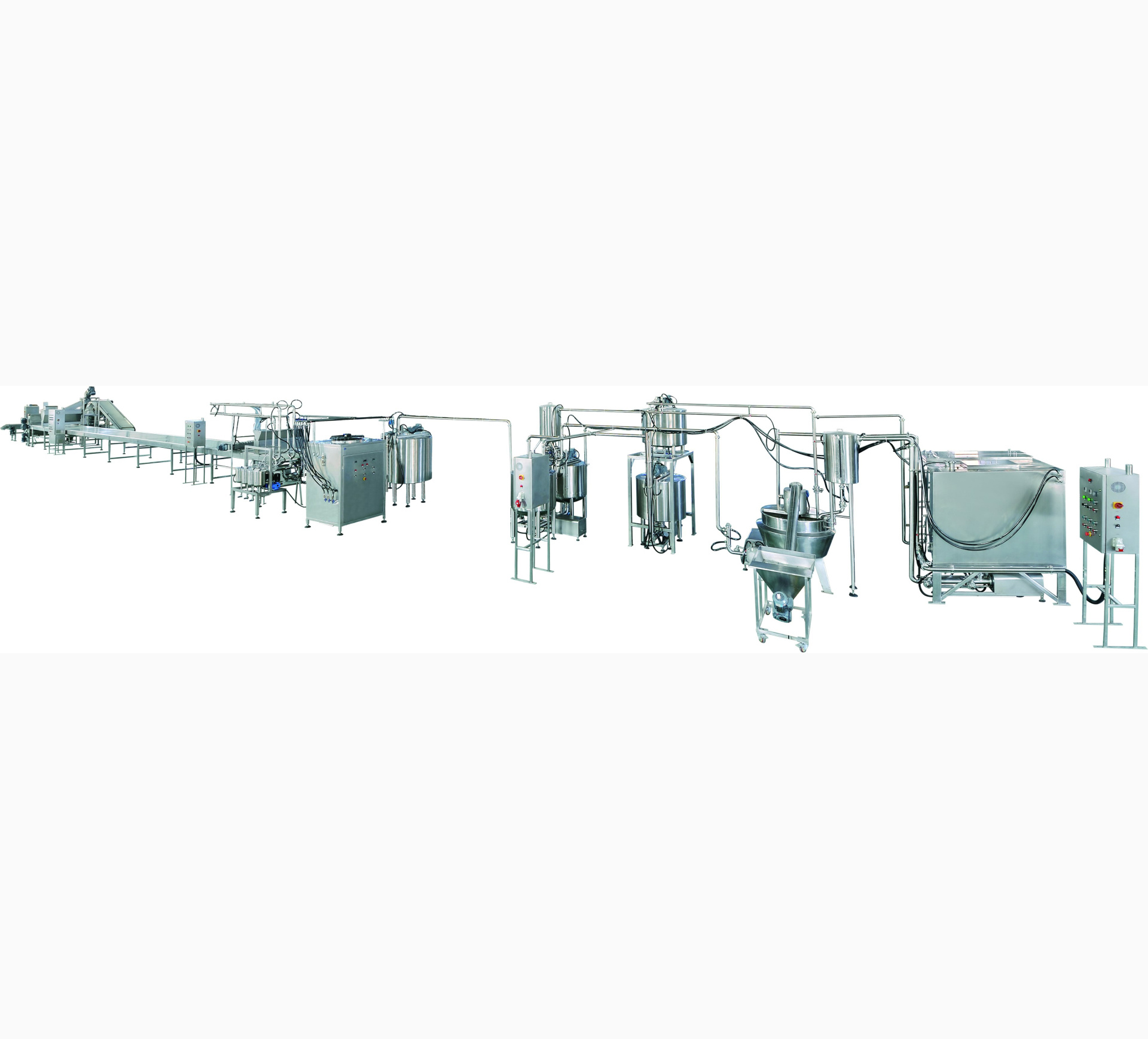

When it comes to the production of chocolate, the right chocolate equipment is crucial for achieving both efficiency and quality. The chocolate manufacturing process encompasses several stages, from bean to bar, and requires specialized machinery tailored for each step. Understanding the various types of chocolate equipment can help manufacturers streamline their processes, improve product consistency, and enhance flavor profiles.

One of the primary components of chocolate production is the grinding equipment. This machinery is responsible for reducing cocoa beans and nibs into a fine paste known as chocolate liquor. A well-designed grinder ensures that the particle size is uniform, which is essential for achieving a smooth texture in the final product. Additionally, the grinding process impacts the flavor extraction from the cocoa beans, making it a critical stage in chocolate production.

Once the chocolate liquor is obtained, it's often necessary to refine the mixture further. This is where conching equipment comes into play. Conching is a process that involves continuously mixing and aerating the chocolate mass to develop its flavor and texture. High-quality conching machines can significantly improve the mouthfeel of chocolate, transforming it into a velvety experience for consumers.

Temperatures also play a vital role in chocolate production, especially during the tempering process. Tempering equipment is designed to heat and cool chocolate to specific temperatures, ensuring the cocoa butter crystals form correctly. Properly tempered chocolate not only has a glossy finish but also a satisfying snap when broken. This equipment is essential for manufacturers aiming to create premium chocolate products that stand out in the competitive market.

In addition to these essential machines, packaging equipment also plays a critical role in ensuring the freshness and appeal of chocolate products. Automated packaging systems help streamline the process of wrapping and boxing chocolate, which can speed up production and reduce labor costs. Effective packaging also protects the chocolate from moisture and light, preserving its quality for longer periods.

Investing in the right chocolate equipment can yield numerous benefits for manufacturers. Not only does it enhance the quality of the final product, but it also improves production efficiency and reduces waste. As consumer preferences shift towards artisanal and high-quality chocolate products, utilizing advanced chocolate machinery can give manufacturers a competitive edge.

In conclusion, understanding the various types of chocolate equipment and their functions is essential for anyone in the chocolate manufacturing industry. By optimizing each stage of the production process, manufacturers can create exceptional chocolate products that meet the increasing demand for quality and innovation. Embracing the right technology in chocolate production is key to enhancing your brand's reputation and satisfying consumer expectations.

One of the primary components of chocolate production is the grinding equipment. This machinery is responsible for reducing cocoa beans and nibs into a fine paste known as chocolate liquor. A well-designed grinder ensures that the particle size is uniform, which is essential for achieving a smooth texture in the final product. Additionally, the grinding process impacts the flavor extraction from the cocoa beans, making it a critical stage in chocolate production.

Once the chocolate liquor is obtained, it's often necessary to refine the mixture further. This is where conching equipment comes into play. Conching is a process that involves continuously mixing and aerating the chocolate mass to develop its flavor and texture. High-quality conching machines can significantly improve the mouthfeel of chocolate, transforming it into a velvety experience for consumers.

Temperatures also play a vital role in chocolate production, especially during the tempering process. Tempering equipment is designed to heat and cool chocolate to specific temperatures, ensuring the cocoa butter crystals form correctly. Properly tempered chocolate not only has a glossy finish but also a satisfying snap when broken. This equipment is essential for manufacturers aiming to create premium chocolate products that stand out in the competitive market.

In addition to these essential machines, packaging equipment also plays a critical role in ensuring the freshness and appeal of chocolate products. Automated packaging systems help streamline the process of wrapping and boxing chocolate, which can speed up production and reduce labor costs. Effective packaging also protects the chocolate from moisture and light, preserving its quality for longer periods.

Investing in the right chocolate equipment can yield numerous benefits for manufacturers. Not only does it enhance the quality of the final product, but it also improves production efficiency and reduces waste. As consumer preferences shift towards artisanal and high-quality chocolate products, utilizing advanced chocolate machinery can give manufacturers a competitive edge.

In conclusion, understanding the various types of chocolate equipment and their functions is essential for anyone in the chocolate manufacturing industry. By optimizing each stage of the production process, manufacturers can create exceptional chocolate products that meet the increasing demand for quality and innovation. Embracing the right technology in chocolate production is key to enhancing your brand's reputation and satisfying consumer expectations.

Chocolate equipment

Previous Page