The Sweet Science: Candy Making Machines Revolutionizing Production

2025/07/10

The Sweet Science: How Candy Making Machines Transform Production

Table of Contents

- Introduction to Candy Making Machines

- A Brief History of Candy Production

- Importance of Automation in Candy Manufacturing

- Types of Candy Making Machines and Their Functions

- The Candy Production Process: From Raw Ingredients to Finished Products

- How Candy Making Machines Enhance Production Efficiency

- Innovations in Candy Manufacturing Technology

- The Future of Candy Production: Trends and Predictions

- Conclusion: Embracing the Sweet Science

- Frequently Asked Questions

Introduction to Candy Making Machines

The confectionery industry is a delightful sector where creativity meets precision. One of the most significant advancements in this field is the introduction of **candy making machines**. These machines have redefined how candy is produced, ensuring consistency and quality while drastically increasing production speed. The combination of technology and culinary art has led to innovative processes that can cater to consumer demand more efficiently than ever before.

A Brief History of Candy Production

Candy has a rich history that dates back thousands of years. Initially, sweets were made by hand using simple tools. As demand grew, so did the need for more efficient production methods. The first candy making machines emerged in the 19th century, revolutionizing the industry. These early machines laid the groundwork for the complex machinery we see today, which can automate nearly every step of the production process.

Early Innovations in Candy Production

In the early days, sugar was a luxury item, and candy making was a meticulous process. Innovations such as the steam engine allowed for more significant production capabilities. The introduction of machines that could mix, cook, and mold candy led to the mass production of sweets, making them more accessible to the general public.

Importance of Automation in Candy Manufacturing

Automation in candy manufacturing is crucial for several reasons. It allows for consistency in product quality, reduces labor costs, and increases production speed. **Candy making machines** streamline processes that once required extensive manual labor, making it possible to produce more goods in less time without sacrificing quality.

Cost Efficiency and Profitability

Investing in automated candy making machines can lead to significant cost savings. By reducing labor costs and minimizing waste, manufacturers can increase their profit margins. Additionally, the ability to produce larger quantities without compromising quality allows businesses to meet market demand effectively.

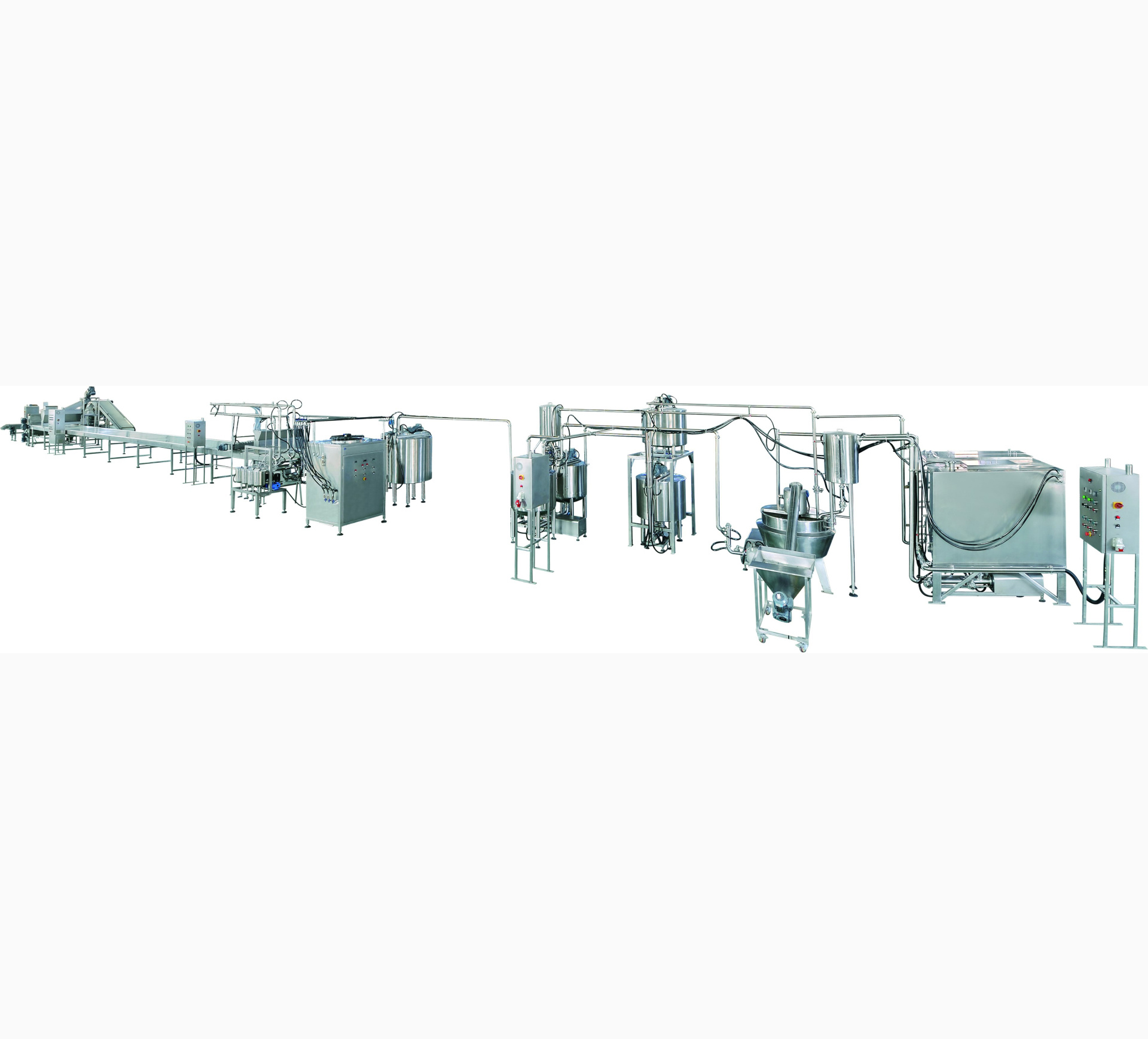

Types of Candy Making Machines and Their Functions

Candy making machines come in various types, each designed to fulfill specific functions in the production process. Understanding these machines is vital for manufacturers looking to optimize their operations.

1. Mixers and Cookers

Mixers and cookers play a crucial role in the initial stages of candy production. These machines blend ingredients such as sugar, corn syrup, and flavorings to create a consistent mixture. Cookers then heat the mixture to specific temperatures, ensuring that the sugar dissolves fully and the desired texture is achieved.

2. Depositors

Depositors are used to shape and mold candies into their final form. These machines can create a variety of shapes and sizes, from gummy bears to chocolate bars. The precision of depositors ensures that each piece of candy is uniform, maintaining the brand's quality standard.

3. Cooling Tunnels

Once candies are shaped, they need to cool properly to retain their structure. Cooling tunnels are designed to provide a controlled environment for candies to solidify. This step is essential, especially for chocolate products, as it prevents bloom and ensures a smooth finish.

4. Wrapping Machines

The final step in candy production often involves wrapping and packaging. Wrapping machines automate this process, ensuring that candies are securely packaged for distribution. This not only enhances product shelf life but also improves presentation for consumers.

The Candy Production Process: From Raw Ingredients to Finished Products

To truly appreciate the impact of candy making machines, it’s essential to understand the production process. This involves multiple stages, each critical to the final product.

1. Ingredient Preparation

The candy-making journey begins with the preparation of raw ingredients. This includes weighing and measuring sugars, flavorings, and other components. Automation in this stage can enhance accuracy and reduce waste.

2. Cooking and Mixing

After preparation, the ingredients are mixed and cooked. The process requires strict temperature controls to achieve the right texture and flavor. Modern machines can monitor temperatures and adjust cooking times automatically, ensuring optimal results.

3. Molding and Shaping

Once the mixture is cooked, it is deposited into molds. This process is rapidly executed by depositors, which can create candies in various shapes and sizes. This versatility allows manufacturers to experiment with different designs and flavors.

4. Cooling and Hardening

As candies cool, they solidify into their final shape. This step is crucial, particularly for chocolates and other confections. Cooling tunnels help maintain the ideal temperature and humidity levels to ensure proper hardening.

5. Packaging

The last stage of production involves packaging the finished candies. Wrapping machines automatically wrap candies, ensuring that they are sealed and ready for sale. Efficient packaging not only preserves freshness but also enhances the product’s market appeal.

How Candy Making Machines Enhance Production Efficiency

Efficiency is a key driver of success in the confectionery industry. **Candy making machines** bring several benefits to streamline operations and maximize output.

1. Speed and Scalability

Automated machines can operate at high speeds, producing large quantities of candy in a fraction of the time it would take to produce manually. This scalability allows manufacturers to respond quickly to market demands and seasonal trends.

2. Quality Control

With automation comes enhanced quality control. Machines can be programmed to meet specific standards, reducing the likelihood of human error. This consistency is vital for maintaining brand reputation and customer satisfaction.

3. Reduced Labor Requirements

By minimizing the need for manual labor, candy making machines can reduce operational costs significantly. This shift not only lowers expenses but also allows staff to focus on more complex tasks, such as quality assurance and product development.

Innovations in Candy Manufacturing Technology

The candy manufacturing sector is continually evolving. New technologies are emerging that further optimize production and cater to consumer preferences.

1. Smart Machines

The integration of smart technology into candy making machines is revolutionizing the industry. These machines can be equipped with sensors that monitor performance and detect potential issues before they become significant problems. This proactive approach to maintenance helps reduce downtime and increases efficiency.

2. Sustainable Practices

As consumers become more environmentally conscious, manufacturers are exploring sustainable practices. New machines are designed to minimize energy consumption and reduce waste, aligning production with green initiatives.

3. Customization and Personalization

Consumers are increasingly seeking unique and personalized products. Modern candy making machines can be programmed to create customized flavors, designs, and packaging, allowing brands to cater to individual tastes and preferences.

The Future of Candy Production: Trends and Predictions

Looking ahead, the candy manufacturing landscape is poised for significant changes driven by technological advancements and consumer trends.

1. Increased Focus on Healthier Options

As health consciousness rises, manufacturers will likely pivot toward producing healthier candy options. This shift may include using natural sweeteners, reducing sugar content, and incorporating functional ingredients.

2. Advanced Automation

The future will see even more sophisticated candy making machines that leverage artificial intelligence and machine learning. These technologies will further enhance production efficiency and quality control, pushing the envelope of what is possible in candy manufacturing.

3. Global Market Expansion

With globalization, there is a growing demand for diverse candy products from different cultures. Manufacturers will need to adapt their machines and processes to cater to international markets, ensuring that they meet varying consumer preferences and regulatory standards.

Conclusion: Embracing the Sweet Science

The evolution of candy making machines has dramatically transformed the production process in the confectionery industry. As we embrace these advancements, the future of candy production looks promising, with innovations that prioritize efficiency, quality, and sustainability. By understanding the importance of automation and the various types of machines available, manufacturers can position themselves at the forefront of this delightful industry, ensuring that they meet consumer demands while maintaining the artistry of candy making.

Frequently Asked Questions

1. What are the main types of candy making machines?

Candy making machines include mixers, cookers, depositors, cooling tunnels, and wrapping machines, each serving a unique function in the production process.

2. How do candy making machines improve efficiency?

These machines automate various processes, reducing the need for manual labor, increasing speed, and ensuring consistent product quality.

3. Are there sustainable options for candy making machines?

Yes, many newer machines are designed to minimize energy consumption and waste, aligning with sustainable production practices.

4. What innovations are shaping the future of candy production?

Innovations in smart technology, customization options, and a focus on healthier ingredients are all influencing the future of candy manufacturing.

5. How can manufacturers ensure quality control in candy production?

By utilizing automated machines equipped with sensors, manufacturers can monitor production closely and maintain consistent quality standards.

Candy making machines