Aeration Systems and Their Role in Enhancing Air Quality in Manufacturing Facilities

2025/07/12

Aeration Systems and Their Role in Enhancing Air Quality in Manufacturing Facilities

Air quality in manufacturing facilities is a crucial concern for both employee well-being and operational efficiency. Poor air quality can lead to a myriad of health issues for workers, including respiratory problems, fatigue, and decreased productivity. Aeration systems play a pivotal role in mitigating these challenges by effectively improving air quality. This article delves deep into the various types of aeration systems, their benefits, and the best practices for implementation in manufacturing environments.

Table of Contents

1. Understanding Aeration Systems

2. Importance of Air Quality in Manufacturing

3. Types of Aeration Systems Used in Factories

3.1 Natural Aeration Systems

3.2 Mechanical Aeration Systems

3.3 Hybrid Aeration Systems

4. Key Benefits of Aeration Systems

4.1 Improved Worker Health

4.2 Enhanced Productivity

4.3 Compliance with Regulations

5. Best Practices for Implementing Aeration Systems

6. Maintaining Aeration Systems for Optimal Performance

7. Case Studies: Successful Aeration Implementation

8. FAQs about Aeration Systems

9. Conclusion

1. Understanding Aeration Systems

Aeration systems are designed to enhance the air quality within a space by introducing fresh air and removing contaminants. These systems use various methods—both natural and mechanical—to facilitate air movement and exchange, thereby ensuring a healthier environment for all occupants.

2. Importance of Air Quality in Manufacturing

The manufacturing sector often involves the use of hazardous materials, chemicals, and processes that can lead to the accumulation of harmful airborne particles. Ensuring high air quality is essential for:

- **Protecting Employee Health**: Poor air quality can exacerbate existing health conditions and lead to new ones, affecting the overall workforce.

- **Boosting Operational Efficiency**: Clean air supports better focus, enabling workers to perform optimally.

- **Meeting Regulatory Standards**: Many industries are bound by regulations that mandate specific air quality standards.

3. Types of Aeration Systems Used in Factories

Understanding the types of aeration systems is critical for selecting the right solution for your manufacturing facility.

3.1 Natural Aeration Systems

Natural aeration utilizes passive techniques to enhance air circulation. This could involve:

- **Windows and Vents**: Strategic placement allows for cross-ventilation.

- **Design Features**: Architectural elements that promote air flow naturally.

While cost-effective, natural aeration is dependent on external weather conditions and may not always provide adequate air circulation.

3.2 Mechanical Aeration Systems

Mechanical systems incorporate fans and blowers to actively circulate air within the environment. Benefits include:

- **Consistent Airflow**: Provides a reliable means of maintaining air quality regardless of external conditions.

- **Enhanced Filtration**: Many mechanical systems come equipped with advanced filtration options to trap airborne contaminants.

Examples include HVAC systems specifically designed for industrial use.

3.3 Hybrid Aeration Systems

Hybrid systems combine both natural and mechanical techniques. They leverage the strengths of each approach, allowing for flexibility and adaptability in air quality management.

4. Key Benefits of Aeration Systems

Implementing aeration systems in manufacturing facilities can yield multiple advantages.

4.1 Improved Worker Health

A significant benefit of aeration systems is their role in promoting better health among workers. Cleaner air reduces the risk of respiratory issues and improves overall employee morale.

4.2 Enhanced Productivity

When workers breathe clean, fresh air, they tend to be more alert and focused. This translates to higher productivity levels, which is crucial for meeting operational goals.

4.3 Compliance with Regulations

With increasing regulations surrounding workplace safety, effective aeration systems help facilities comply with local and international air quality standards, avoiding potential fines and legal issues.

5. Best Practices for Implementing Aeration Systems

To maximize the benefits of aeration systems, consider the following best practices:

- **Assess Air Quality Needs**: Conduct a thorough evaluation of your facility's air quality requirements.

- **Choose Appropriate Systems**: Select aeration systems that best fit your operational processes and facility layout.

- **Engage Professionals**: Work with HVAC specialists to ensure proper installation and integration of systems.

6. Maintaining Aeration Systems for Optimal Performance

Regular maintenance of aeration systems is essential for sustained performance. Key maintenance practices include:

- **Routine Inspections**: Schedule regular checks on system components.

- **Filter Replacements**: Replace filters as per manufacturer recommendations to ensure optimal air quality.

- **Monitor Performance**: Utilize sensors and monitoring systems to track air quality levels continuously.

7. Case Studies: Successful Aeration Implementation

Examining real-world examples can provide valuable insights into effective aeration strategies. Several manufacturing companies have successfully integrated aeration systems, resulting in improved air quality, enhanced worker safety, and increased productivity.

For instance, a leading automotive manufacturer overhauled its ventilation systems, implementing both mechanical and natural aeration techniques. As a result, they reported a significant decrease in airborne contaminants and a marked increase in employee satisfaction and productivity.

8. FAQs about Aeration Systems

What are aeration systems?

Aeration systems are designed to improve air quality by facilitating air circulation and removing contaminants in indoor environments.

How do I know if my factory needs an aeration system?

If your facility has issues related to poor air quality, increased worker health complaints, or is not compliant with local regulations, it may be time to consider an aeration system.

What types of aeration systems are available?

Aeration systems can be categorized into natural, mechanical, and hybrid systems, each with its advantages and applications.

Can aeration systems help reduce energy costs?

Yes, efficient aeration systems can reduce reliance on heating and cooling systems, leading to lower energy costs.

How often should aeration systems be maintained?

Routine inspections and maintenance should be conducted regularly, with specific attention given to filter changes based on usage and manufacturer guidance.

9. Conclusion

Investing in **aeration systems** is an essential step for manufacturing facilities aiming to enhance air quality, promote worker health, and improve overall productivity. By understanding the types of aeration systems available and implementing best practices, facility managers can create a safer and more efficient work environment. Prioritizing air quality is not only a regulatory requirement but a moral obligation to safeguard the health and well-being of workers in the manufacturing sector.

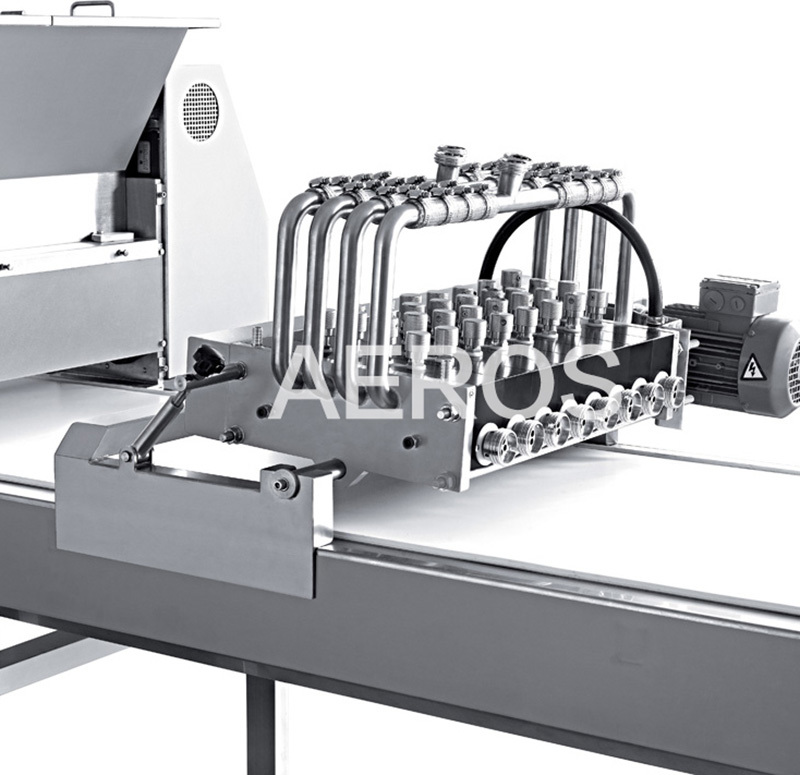

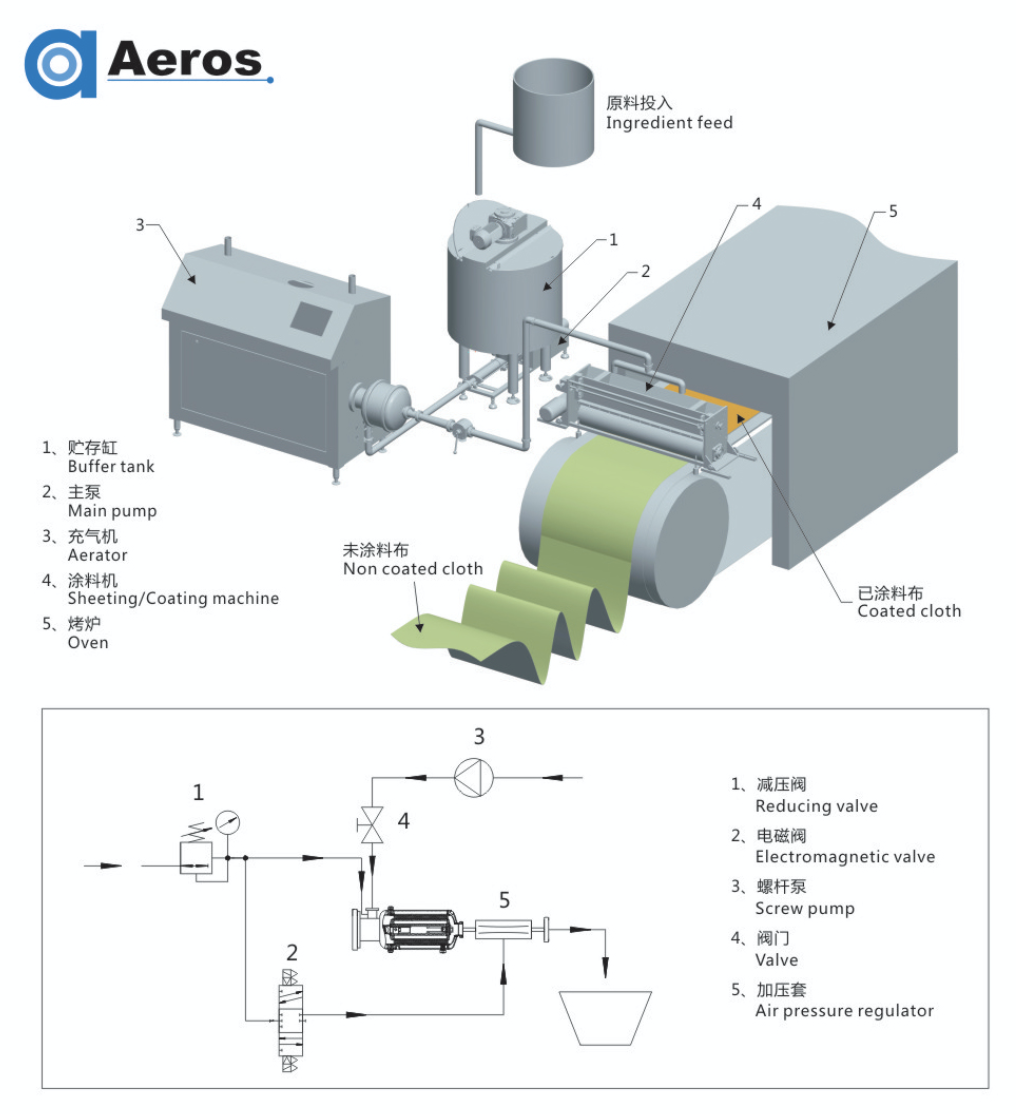

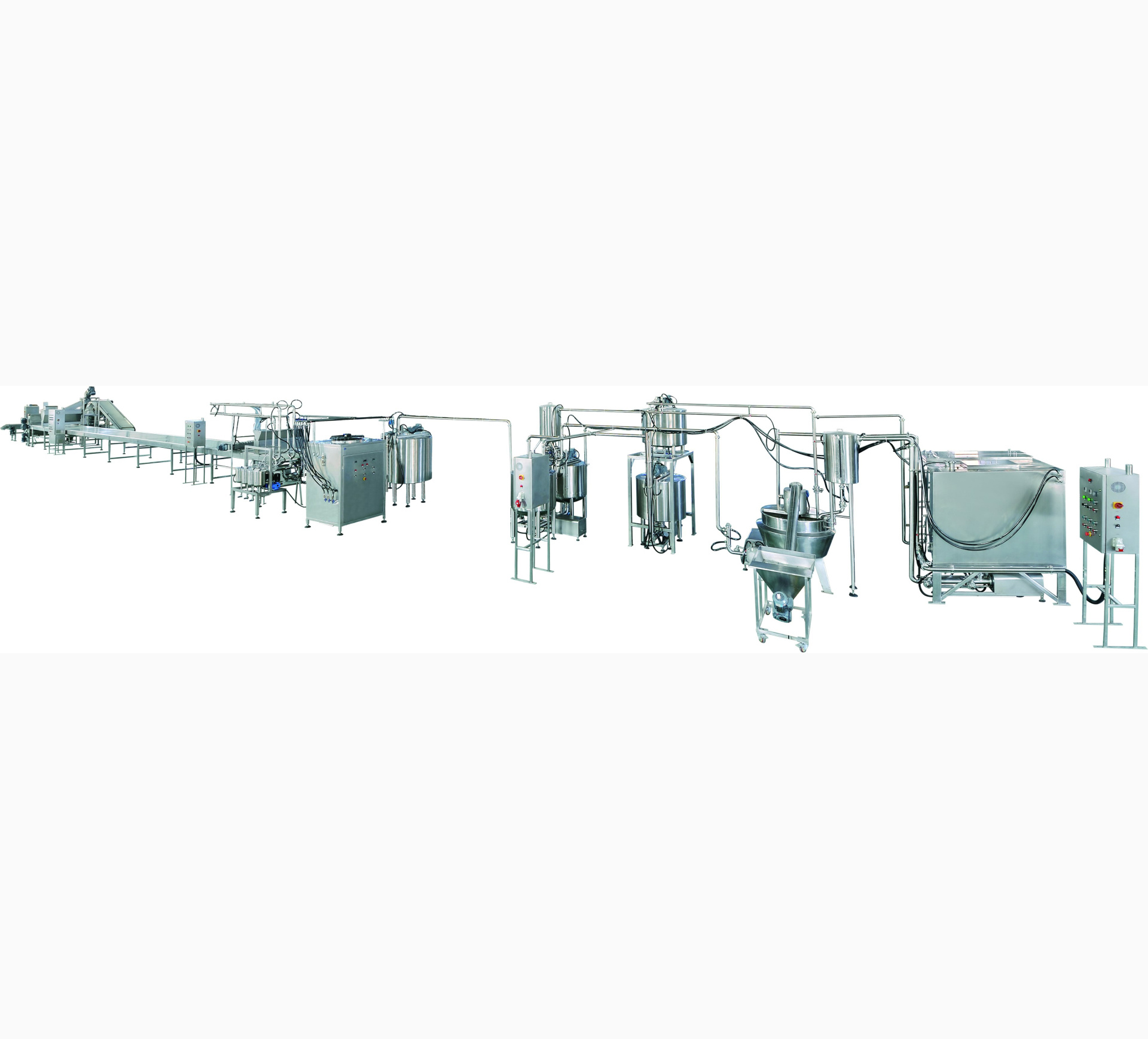

Aeration systems