Revolutionizing Confectionery: The Aerated Chocolate Production Line from China

2025/09/11

In the realm of confectionery, aerated chocolate has carved out a niche for itself, offering unique textures and flavors that delight consumers. The aerated chocolate production line made in China is at the forefront of this trend, providing manufacturers with advanced technology to produce light, fluffy chocolates that stand out in a competitive market.

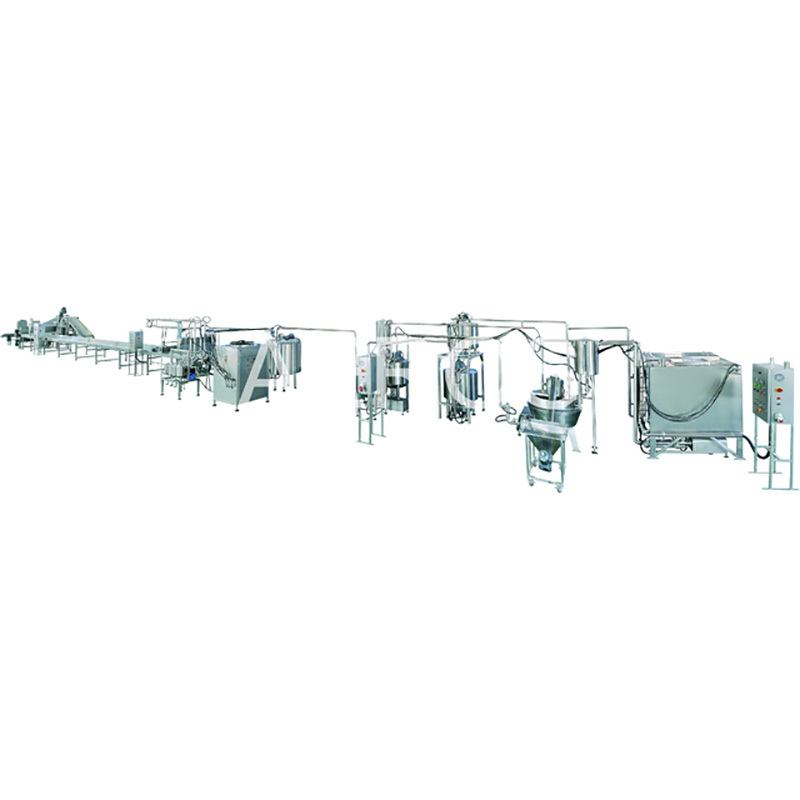

Aerated chocolate, characterized by its incorporation of air bubbles, is produced using a specialized process that requires precision and control. The Chinese manufacturing sector has developed an efficient production line that integrates state-of-the-art machinery, allowing for the systematic mixing, aeration, and molding of chocolate. This production line typically includes several key components such as mixing tanks, aerators, cooling tunnels, and depositor machines, each designed to optimize the aeration process and maintain the quality of the chocolate.

One of the primary benefits of using an aerated chocolate production line is the ability to create a product with a lighter texture and a distinct mouthfeel. The incorporation of air not only affects the density of the chocolate but also enhances its flavor profile, making it more appealing to consumers. This feature is particularly appealing in a market that increasingly values unique and novel eating experiences.

Moreover, the automation involved in the production line significantly reduces labor costs and production times. With the capability for continuous operation and minimal human intervention, manufacturers can scale their production to meet rising demand without sacrificing quality. Additionally, the energy efficiency of modern Chinese manufacturing processes contributes to a more sustainable production model, addressing growing concerns around environmental impact.

Quality control is another critical aspect of the aerated chocolate production line. Advanced systems are in place to ensure that each batch meets the desired specifications for texture, taste, and appearance. By utilizing technologies such as real-time monitoring and data analytics, manufacturers can quickly identify and rectify any deviations in production, ensuring a consistent product that meets consumer expectations.

In conclusion, the aerated chocolate production line made in China offers manufacturers a powerful tool to innovate and compete in the dynamic confectionery market. By embracing this technology, producers can not only enhance their product offerings but also improve operational efficiency and sustainability. As the demand for aerated chocolates continues to grow, investing in such advanced production lines will likely prove beneficial for businesses looking to thrive in the industry.

Aerated chocolate, characterized by its incorporation of air bubbles, is produced using a specialized process that requires precision and control. The Chinese manufacturing sector has developed an efficient production line that integrates state-of-the-art machinery, allowing for the systematic mixing, aeration, and molding of chocolate. This production line typically includes several key components such as mixing tanks, aerators, cooling tunnels, and depositor machines, each designed to optimize the aeration process and maintain the quality of the chocolate.

One of the primary benefits of using an aerated chocolate production line is the ability to create a product with a lighter texture and a distinct mouthfeel. The incorporation of air not only affects the density of the chocolate but also enhances its flavor profile, making it more appealing to consumers. This feature is particularly appealing in a market that increasingly values unique and novel eating experiences.

Moreover, the automation involved in the production line significantly reduces labor costs and production times. With the capability for continuous operation and minimal human intervention, manufacturers can scale their production to meet rising demand without sacrificing quality. Additionally, the energy efficiency of modern Chinese manufacturing processes contributes to a more sustainable production model, addressing growing concerns around environmental impact.

Quality control is another critical aspect of the aerated chocolate production line. Advanced systems are in place to ensure that each batch meets the desired specifications for texture, taste, and appearance. By utilizing technologies such as real-time monitoring and data analytics, manufacturers can quickly identify and rectify any deviations in production, ensuring a consistent product that meets consumer expectations.

In conclusion, the aerated chocolate production line made in China offers manufacturers a powerful tool to innovate and compete in the dynamic confectionery market. By embracing this technology, producers can not only enhance their product offerings but also improve operational efficiency and sustainability. As the demand for aerated chocolates continues to grow, investing in such advanced production lines will likely prove beneficial for businesses looking to thrive in the industry.

Aerated chocolate production line made in china