Unlocking Efficiency: How Aeration Systems from China Transform Food Processing

2025/09/22

Unlocking Efficiency: How Aeration Systems from China Transform Food Processing

Table of Contents

- 1. Introduction to Aeration Systems in Food Processing

- 2. Importance of Aeration in Food and Beverage Manufacturing

- 3. Types of Aeration Systems Used in the Industry

- 4. Benefits of Aeration Systems from China

- 5. Technological Advancements in Aeration Systems

- 6. Case Studies: Success Stories of Aeration Systems

- 7. Future Trends in Food Processing Aeration Technologies

- 8. FAQs about Aeration Systems in Food Processing

- 9. Conclusion

1. Introduction to Aeration Systems in Food Processing

In the realm of food processing, efficiency and safety are paramount. Aeration systems play a crucial role in ensuring that food and beverage products meet rigorous quality standards. These systems enhance the mixing, fermentation, and preservation processes, thus unlocking significant operational efficiencies. As the industry continues to evolve, aeration technologies developed in China are setting the benchmark for innovation and effectiveness.

2. Importance of Aeration in Food and Beverage Manufacturing

Aeration is not merely an optional process; it is fundamental to various food and beverage applications. By introducing air or other gases into liquids, manufacturers can achieve several vital objectives:

2.1 Enhancing Fermentation Processes

In brewing and winemaking, aeration plays a pivotal role in promoting yeast activity. The right levels of oxygen can enhance fermentation efficiency, resulting in higher yields and better flavors.

2.2 Improving Product Texture and Quality

Aeration is essential in creating desirable textures in products like whipped cream, mousses, and even certain baked goods. By incorporating air, manufacturers can achieve the lightness and fluffiness that consumers expect.

2.3 Extending Shelf Life

Introducing controlled levels of aeration can inhibit bacterial growth, thereby extending the shelf life of perishable items. This is particularly important in the production of sauces, dressings, and dairy products.

3. Types of Aeration Systems Used in the Industry

In food processing, a variety of aeration systems are employed, each tailored to specific applications and product types.

3.1 Static Aerators

Static aerators are simple devices that rely on gravity and natural convection to mix air with liquids. They are often used in applications where gentle mixing is needed, such as in salad dressings or sauces.

3.2 Mechanical Aerators

Mechanical aerators utilize pumps and blades to actively introduce air into liquids. They are widely used in large-scale brewing and wastewater treatment processes, where thorough mixing is crucial.

3.3 Diffused Aeration Systems

These systems introduce air through fine bubbles, providing a high surface area for gas exchange. They are commonly used in fermentation processes, ensuring optimal yeast health and activity.

4. Benefits of Aeration Systems from China

Chinese aeration systems offer numerous advantages that can significantly enhance the efficiency of food processing operations.

4.1 Cost-Effectiveness

Manufactured at scale, Chinese aeration systems often come at a lower cost without sacrificing quality. This affordability allows small and medium-sized enterprises to access advanced technologies.

4.2 Energy Efficiency

Many modern Chinese aeration systems are designed with energy efficiency in mind. By reducing energy consumption during operation, manufacturers can achieve cost savings while minimizing their environmental impact.

4.3 Customization and Flexibility

Chinese manufacturers often provide customizable solutions tailored to specific production needs. This flexibility allows food processors to implement aeration systems that align perfectly with their operational requirements.

4.4 Enhanced Automation

With the rise of Industry 4.0, many aeration systems from China are equipped with IoT capabilities. This allows for real-time monitoring and adjustments, ensuring optimal performance and minimal downtime.

5. Technological Advancements in Aeration Systems

The landscape of aeration technology is constantly evolving. Recent advancements have made these systems more efficient, reliable, and easier to integrate into existing processing lines.

5.1 Advanced Sensor Technologies

Modern aeration systems are now equipped with sensors that monitor oxygen levels, temperature, and pressure. This data enables processors to make informed decisions, optimizing the aeration process in real-time.

5.2 Automation and Control Systems

Automated aeration systems can be programmed to adjust aeration rates based on real-time feedback. This level of control enhances precision in fermentation processes, leading to improved product consistency.

5.3 Integration with Other Processing Technologies

Aeration systems are increasingly being integrated with other food processing technologies, such as pasteurization and homogenization. This integration facilitates a seamless workflow, reducing the time and resources needed for production.

6. Case Studies: Success Stories of Aeration Systems

To illustrate the transformative impact of aeration systems, we can look at several case studies from leading food processing companies.

6.1 Case Study: A Leading Brewery in China

A major brewery implemented a mechanical aeration system, resulting in a 30% increase in fermentation efficiency. By optimizing the aeration process, the brewery was able to reduce production time and improve the flavor profile of its beers.

6.2 Case Study: An International Dairy Producer

An international dairy producer adopted a diffused aeration system to improve the shelf life of its products. The new system not only extended the product's freshness but also reduced spoilage rates by 25%.

6.3 Case Study: A Sauce Manufacturer

A sauce manufacturer integrated advanced aeration technology into its production line, achieving a consistent texture across products. The implementation led to increased customer satisfaction and a 15% rise in sales.

7. Future Trends in Food Processing Aeration Technologies

As we look to the future, several trends in aeration technologies are emerging that promise to further revolutionize food processing.

7.1 Sustainable Practices

There is a growing emphasis on sustainability within the food processing industry. Future aeration systems will likely incorporate eco-friendly materials and processes to minimize environmental impact.

7.2 Increased Use of AI and Machine Learning

Artificial intelligence and machine learning are set to play a significant role in optimizing aeration processes. These technologies will allow for predictive maintenance and efficiency improvements based on historical data.

7.3 Greater Focus on Food Safety

With increasing consumer concerns regarding food safety, aeration systems will evolve to incorporate advanced filtration and monitoring technologies, ensuring that products are produced under the safest conditions.

8. FAQs about Aeration Systems in Food Processing

8.1 What is the primary function of aeration in food processing?

Aeration primarily serves to mix air into liquids, enhancing fermentation, improving product texture, and extending shelf life.

8.2 How do aeration systems impact food quality?

By ensuring optimal oxygen levels and mixing, aeration systems can enhance flavors, textures, and overall product quality.

8.3 Are Chinese aeration systems reliable?

Yes, many Chinese manufacturers produce high-quality, reliable aeration systems that meet international standards.

8.4 What industries use aeration systems?

Aeration systems are widely used in breweries, dairies, sauce production, and any food processing operation that requires mixing and fermentation.

8.5 How can I choose the right aeration system for my operation?

Consider factors such as the specific application, production volume, budget, and desired level of automation when selecting an aeration system.

9. Conclusion

Aeration systems from China are transforming the food processing landscape by unlocking new levels of efficiency and product quality. By understanding their importance and embracing the latest technological advancements, food manufacturers can significantly enhance their operations. As this sector continues to evolve, staying informed about these advancements will be essential for maintaining competitiveness in an ever-changing market.

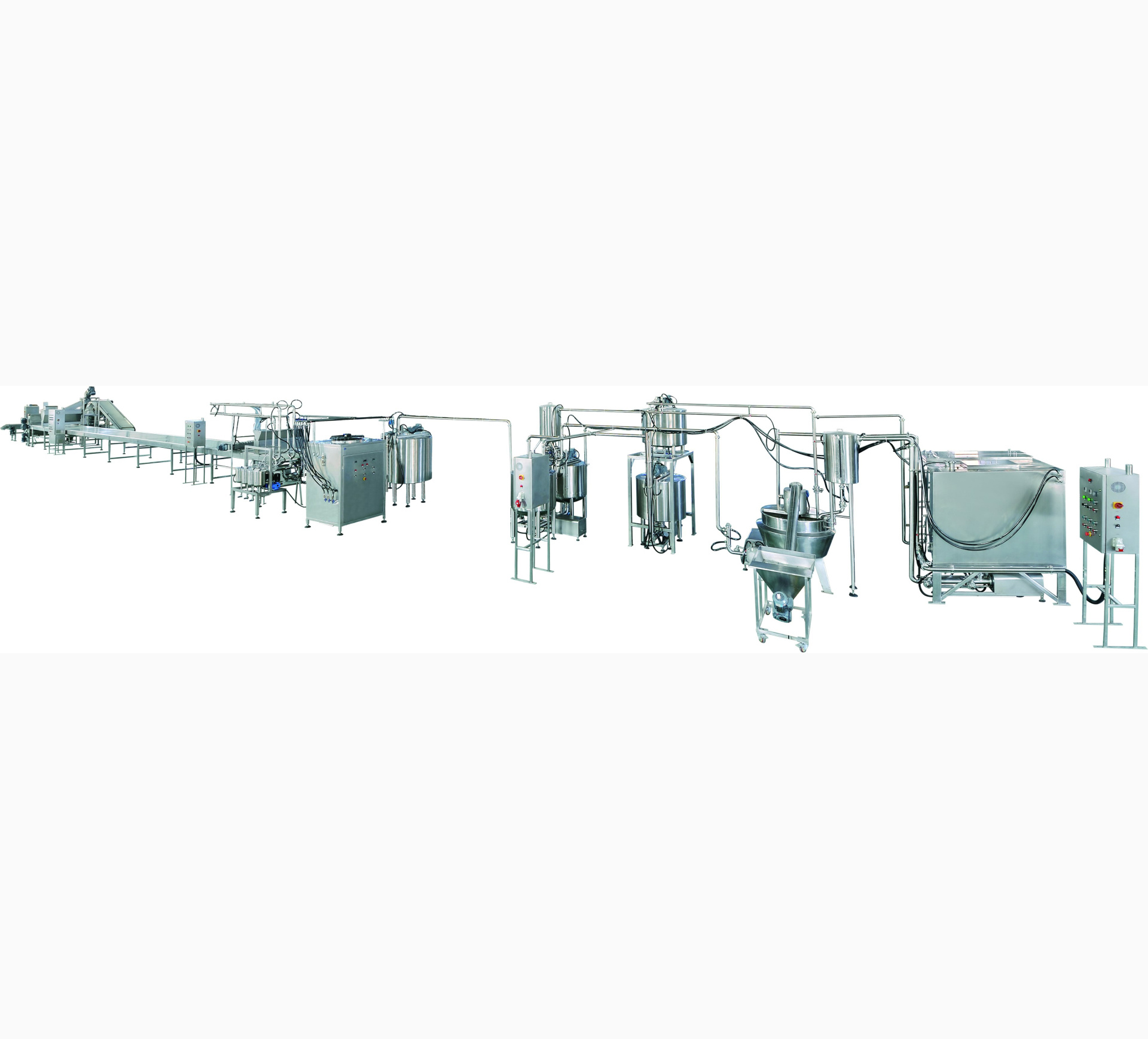

Aeration system from china