Unveiling the Secrets of Marshmallow Production Lines from China

2025/09/28

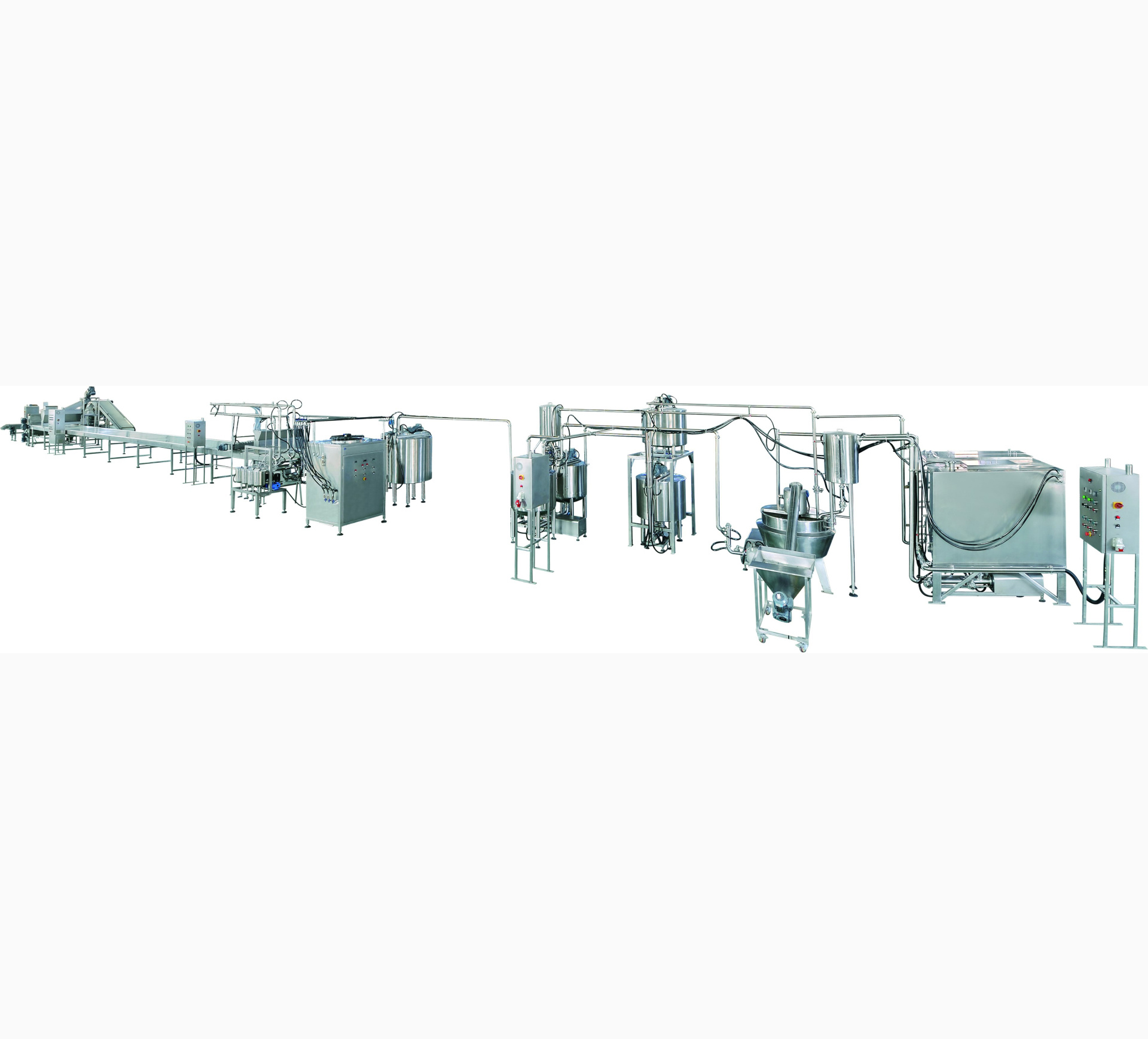

Marshmallow production lines from China have become increasingly popular due to their cutting-edge technology and high efficiency. These production lines are specifically designed for the manufacturing of marshmallows, a beloved confectionery enjoyed worldwide. The process of creating marshmallows involves several key steps, including mixing, cooking, cooling, and cutting, all of which can be efficiently managed by automated machinery.

The first step in marshmallow production is the mixing of ingredients, which typically includes sugar, corn syrup, gelatin, and water. A high-quality production line often features sophisticated mixers that ensure a consistent blend of these components. This is crucial, as the texture and taste of the final product depend heavily on the uniformity of the mixture. Advanced mixing technologies help to optimize the mixing time and improve productivity.

Once the mixture is ready, it needs to be cooked to a specific temperature to activate the gelatin and achieve the desired consistency. Chinese marshmallow production lines are equipped with precision cooking systems that allow for accurate temperature control, ensuring that each batch meets quality standards. This step is vital as it affects the flavor profile and final texture of the marshmallows; undercooking or overcooking can lead to undesirable results.

Cooling is the next critical phase, where the cooked mixture is allowed to set. This involves transferring the hot mixture into cooling trays or tunnels. Many modern production lines feature innovative cooling techniques that can significantly reduce the cooling time, allowing manufacturers to increase their output without compromising on quality.

Finally, the cooled marshmallow mass is cut into desired shapes and sizes. Automated cutting machines are integral to this stage, as they ensure precision and uniformity, which are essential for product consistency. This not only enhances the visual appeal of the marshmallows but also facilitates packaging and distribution.

Moreover, investing in a marshmallow production line from China can lead to significant cost savings. The efficiency of these machines can reduce labor costs and increase production capacity, allowing manufacturers to meet market demands more swiftly. Additionally, many suppliers from China offer flexible customization options, enabling businesses to adapt the production line to their specific requirements.

In summary, marshmallow production lines from China represent a blend of innovation and efficiency, offering manufacturers the tools they need to produce high-quality products consistently. By streamlining the production process, these lines help businesses enhance their profitability while delivering delightful treats to consumers. As the demand for marshmallows continues to grow, investing in such advanced machinery could be a strategic move for businesses looking to thrive in the competitive candy market.

Marshmallow Production Line from china