The Environmental Impact of Chocolate Enrobing Machines in Production

2025/09/28

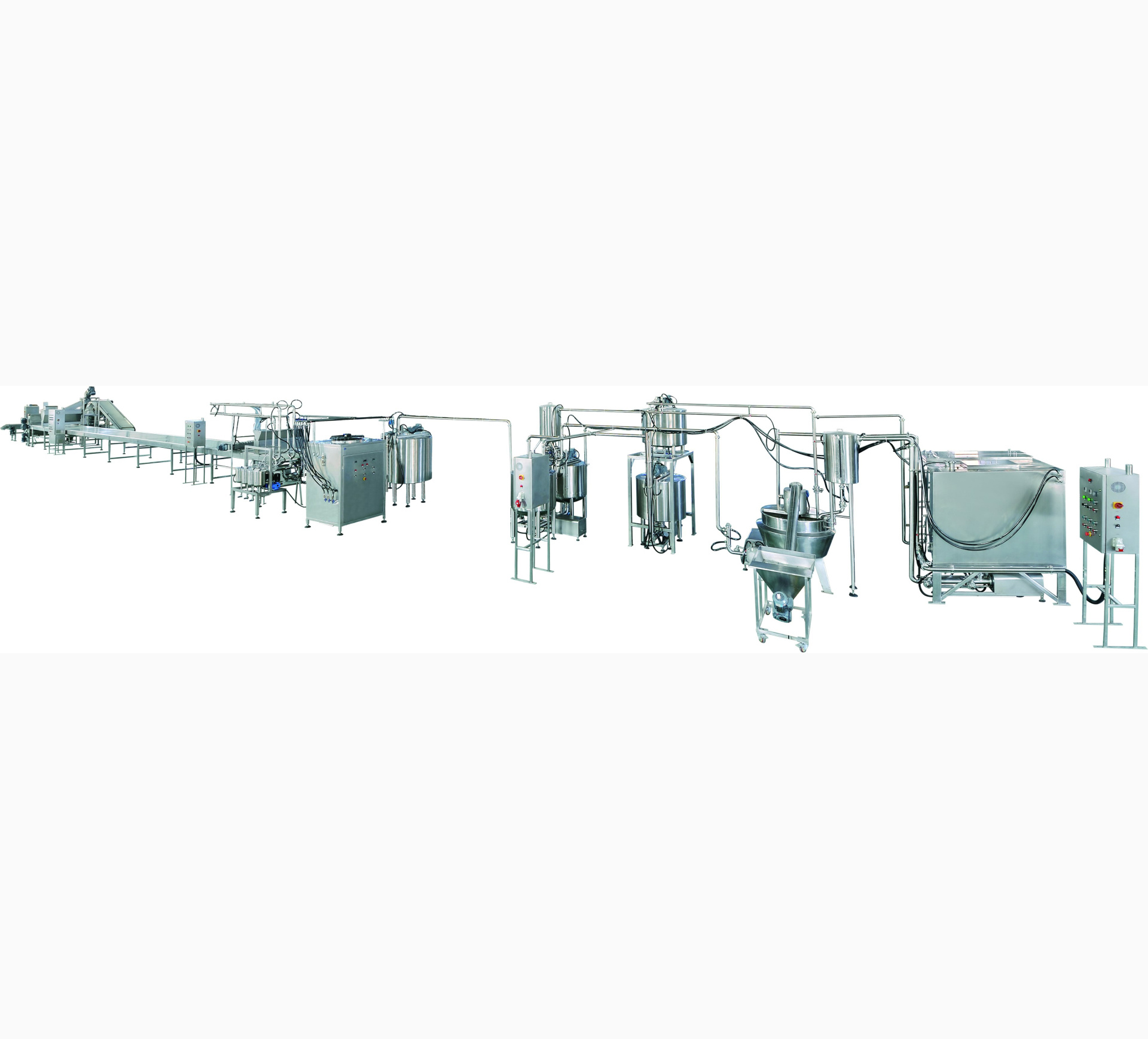

Chocolate enrobing machines are specialized equipment designed to coat confections with a layer of chocolate. They operate by melting chocolate and then applying it to various food products, such as nuts, fruits, or baked goods. These machines come in various forms, including batch and continuous systems, and are essential in achieving a smooth and even chocolate coating.

The enrobing process typically involves several steps, including tempering the chocolate, cooling the coated product, and ensuring quality control measures are in place. Each phase can have different environmental implications, making it vital to understand how these machines impact sustainability.

Environmental Concerns in Food Production

The food production industry is known for its environmental challenges, including resource depletion, pollution, and waste generation. Chocolate enrobing machines contribute to these issues through various means:

1. **Resource Consumption**: The manufacturing and operation of chocolate enrobing machines require significant resources, including water and energy.

2. **Waste Generation**: Production processes can lead to waste in the form of unused chocolate, packaging materials, and defective products.

3. **Pollution**: Emissions from production facilities can contribute to air and water pollution, impacting local ecosystems and communities.

To effectively address these concerns, it is crucial to identify areas where improvements can be made.

Energy Consumption and Emissions

Energy consumption is one of the most significant environmental impacts associated with chocolate enrobing machines. The energy needed to melt chocolate and operate machinery can be substantial, leading to high carbon emissions if not managed effectively.

1. **Electricity Usage**: These machines often rely on electricity to function, which can contribute to greenhouse gas emissions, especially if the energy source is non-renewable.

2. **Heat Production**: Melting chocolate requires maintaining specific temperatures, and the energy consumed can lead to increased operational costs and carbon footprints.

To mitigate these effects, manufacturers must explore energy-efficient technologies and practices.

Sustainable Practices in Chocolate Enrobing

Implementing sustainable practices is essential in reducing the environmental impact of chocolate enrobing machines. Here are some strategies that can be adopted by manufacturers:

1. **Energy Efficiency**: Investing in high-efficiency motors and heating systems can significantly reduce energy consumption. Variable frequency drives (VFDs) can adjust motor speeds according to the workload, further enhancing efficiency.

2. **Waste Management**: Recycling chocolate waste and utilizing biodegradable packaging materials can greatly reduce the environmental footprint. Establishing a waste reduction program can help identify areas for improvement.

3. **Water Conservation**: Implementing water-saving technologies and processes can minimize water usage during production. Examples include closed-loop water systems that recycle water used for cooling.

4. **Sourcing Sustainable Ingredients**: Partnering with suppliers who prioritize sustainable practices in cocoa farming can enhance the overall sustainability of chocolate products.

Innovations in Enrobing Technology

Advancements in technology can lead to more eco-friendly chocolate enrobing processes. Key innovations include:

1. **Smart Machines**: The integration of IoT technology allows for real-time monitoring of energy usage and machine performance. This data can help optimize processes and reduce waste.

2. **Alternative Energy Sources**: Utilizing renewable energy sources, such as solar or wind power, can minimize reliance on fossil fuels and decrease emissions.

3. **Improved Heating Methods**: Technologies such as induction heating can provide energy-efficient solutions for melting chocolate, reducing energy consumption.

These innovations not only improve sustainability but can also enhance the quality of the final product.

Regulatory Standards and Compliance

Compliance with environmental regulations is essential for chocolate manufacturers. Various international and local regulations govern emissions, waste disposal, and resource usage in the food production industry.

1. **Understanding Regulations**: Familiarizing oneself with relevant standards can help manufacturers identify compliance requirements and potential penalties for non-compliance.

2. **Sustainability Certifications**: Obtaining certifications such as ISO 14001 can demonstrate a commitment to environmental management and sustainability.

3. **Continuous Improvement**: Regularly assessing processes and seeking opportunities for improvement can ensure that manufacturers stay compliant and reduce their environmental impact.

Case Studies

Examining real-world examples can provide valuable insights into successful sustainability practices in chocolate enrobing.

1. **Company A**: A leading chocolatier implemented energy-efficient machines and established a waste reduction program, resulting in a 30% decrease in energy consumption and a significant reduction in waste.

2. **Company B**: This manufacturer switched to renewable energy sources and invested in smart technology, allowing for better monitoring of energy usage and a 25% decline in emissions.

These case studies demonstrate that it is possible to balance production efficiency with environmental responsibility.

Frequently Asked Questions

1. What are chocolate enrobing machines?

Chocolate enrobing machines coat various foods with melted chocolate, enhancing their appeal and flavor.

2. How do chocolate enrobing machines impact the environment?

They contribute to energy consumption, waste generation, and pollution, which can harm the environment.

3. What sustainable practices can be adopted in chocolate enrobing?

Energy efficiency, waste management, water conservation, and sourcing sustainable ingredients are key practices.

4. Are there any regulations governing chocolate production?

Yes, various local and international regulations dictate emissions, waste management, and resource usage.

5. How can technology improve sustainability in enrobing processes?

Innovations such as smart machines and alternative energy sources can reduce emissions and enhance efficiency.

Conclusion

The environmental impact of chocolate enrobing machines in production is a critical issue that requires immediate attention from manufacturers. By adopting sustainable practices, investing in innovative technologies, and staying compliant with regulatory standards, companies can significantly reduce their environmental footprint. As consumers become increasingly aware of sustainability issues, manufacturers must take proactive steps towards eco-friendly operations to stay competitive in the market. The journey toward more sustainable chocolate production ultimately benefits not just the planet, but also the industry and consumers who value quality and responsibility.

Chocolate Enrobing Machine made in china