Transforming Your Chocolate Production: The Benefits of Using a Chocolate Aerator from China

2025/09/10

Transforming Your Chocolate Production: The Benefits of Using a Chocolate Aerator from China

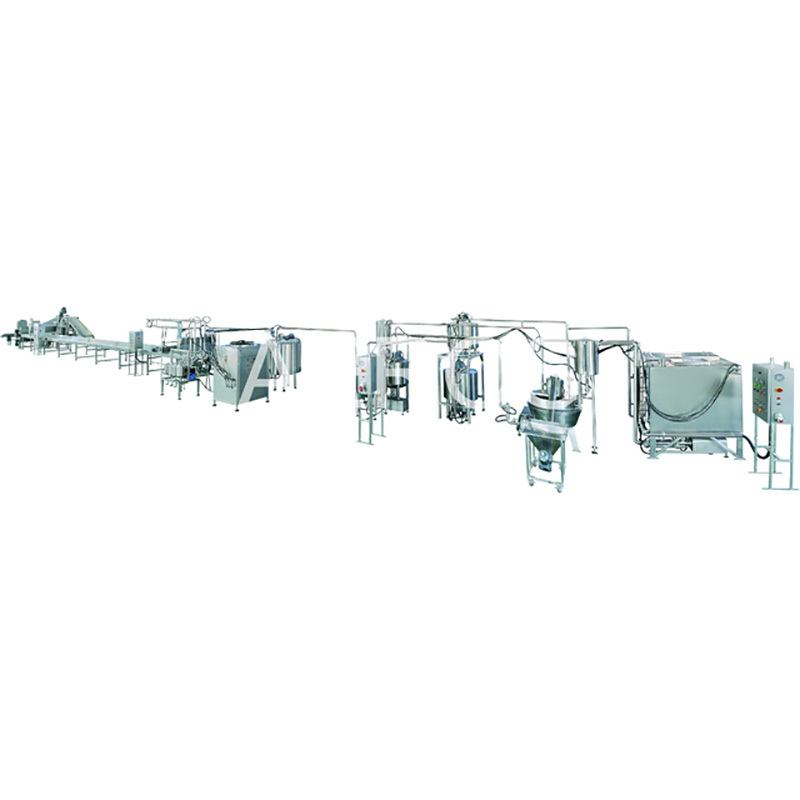

The chocolate production industry has undergone significant changes in recent years, with technological advancements playing a crucial role in enhancing efficiency and product quality. One of the most noteworthy innovations is the chocolate aerator, particularly those manufactured in China. This article delves into the numerous benefits of incorporating a chocolate aerator into your production line, exploring how it can enhance the quality of your chocolate, improve production efficiency, and ultimately transform your business.

The Role of Chocolate Aerators in Production

What is a Chocolate Aerator?

A chocolate aerator is a specialized machine designed to incorporate air into chocolate mixtures during the production process. This aeration process not only alters the texture but also influences the flavor profile and overall quality of the finished product. By introducing controlled amounts of air, chocolate aerators help produce smoother, creamier, and more refined chocolate products.

How Do Chocolate Aerators Work?

Chocolate aerators operate by using various mechanical methods to fold air into the chocolate mixture. The most common techniques involve using high-speed mixing blades or vacuum chambers that create a low-pressure environment, allowing air to be introduced effectively. These machines ensure that the air is evenly distributed throughout the chocolate, resulting in a consistent texture and mouthfeel.

Benefits of Using Chocolate Aerators from China

1. Enhanced Texture and Mouthfeel

One of the primary benefits of using a chocolate aerator is the enhanced texture it provides. By incorporating air, the chocolate becomes lighter and creamier, creating an enjoyable melting experience. This transformation is particularly important for premium chocolate brands looking to differentiate their products in a competitive market.

2. Improved Flavor Profiles

Aerating chocolate can also improve its flavor profile. The introduction of air can help to release and enhance subtle flavor notes that might otherwise be lost. This process allows chocolatiers to create more complex and enjoyable taste experiences for consumers, making their products stand out.

3. Increased Efficiency and Productivity

Chocolate aerators from China are designed with efficiency in mind. By streamlining the production process and reducing the time needed to achieve the desired texture and aeration, these machines can significantly increase overall productivity. This efficiency means fewer labor hours and a faster turnaround time for production runs, allowing businesses to meet growing consumer demand effectively.

4. Cost-Effective Solutions

Investing in a chocolate aerator from China can also be a cost-effective decision. Chinese manufacturers often provide high-quality machinery at competitive prices, allowing businesses to access advanced technology without breaking the bank. This affordability does not come at the expense of quality; many Chinese manufacturers adhere to strict international standards, ensuring reliable and durable equipment.

5. Versatility in Production

Chocolate aerators are not limited to producing a single type of chocolate. They can be used with various chocolate formulations, including dark, milk, and white chocolate. This versatility allows businesses to experiment with different products and formulations, catering to diverse consumer preferences without investing in additional machinery.

Choosing the Right Chocolate Aerator

Factors to Consider

When selecting a chocolate aerator for your production needs, it's essential to consider various factors to ensure optimal performance and results:

1. Production Capacity

Assess the production capacity of the aerator to ensure it meets your production demands. Consider the volume of chocolate you plan to produce and choose a machine that can handle that capacity efficiently.

2. Quality of Materials

Look for aerators made from high-quality, food-grade materials to ensure safety and compliance with industry standards. This consideration will also contribute to the machine's durability and longevity.

3. Energy Efficiency

Energy-efficient machines can help reduce operating costs in the long run. Evaluate the energy consumption of different models to choose one that offers both performance and cost savings.

4. Maintenance Requirements

Choose an aerator that is easy to maintain and clean. Regular maintenance is essential for optimal performance and longevity, so consider machines with accessible parts and straightforward cleaning procedures.

5. Manufacturer Reputation

Research the reputation of the manufacturer. Look for companies with a proven track record of producing reliable and high-quality chocolate aerators. Reading customer reviews and testimonials can provide valuable insights into performance and customer service.

Integrating Chocolate Aerators into Your Production Line

Steps to Successful Integration

Integrating a chocolate aerator into your existing production line requires careful planning and consideration. Here are some steps to ensure a smooth transition:

1. Assess Current Production Processes

Evaluate your current production processes to identify areas where aeration could enhance efficiency and product quality. Understanding these processes will help you determine the best integration points for the aerator.

2. Train Your Staff

Ensure that your production staff is adequately trained in operating the new equipment. Provide training sessions to familiarize them with the machine's features and maintenance requirements.

3. Monitor Performance

After integration, monitor the performance of the chocolate aerator closely. Gather data on production efficiency, product quality, and any challenges that arise to address them promptly.

4. Gather Feedback

Encourage feedback from staff and quality control teams to assess the effectiveness of the aerator in improving chocolate production. This feedback can help you make necessary adjustments and improvements.

5. Continuously Optimize

Once the aerator is successfully integrated, continually look for opportunities to optimize your processes. Regularly review production metrics and identify ways to enhance efficiency and product quality further.

Real-World Applications of Chocolate Aerators

Case Studies of Successful Implementation

Several companies have successfully integrated chocolate aerators from China into their production lines, resulting in significant improvements. Here are a few real-world applications:

1. Premium Chocolate Manufacturers

Many premium chocolate brands have adopted chocolate aerators to create unique textures and flavors that set them apart in the market. By aerating their chocolate, these brands have successfully developed products that offer an exquisite mouthfeel, appealing to discerning consumers.

2. Confectionery Producers

Confectionery producers have found that using chocolate aerators allows them to create lighter, airier products, such as chocolate-covered treats and fillings. This transformation has enhanced their product lines and attracted new customers.

3. Artisan Chocolatiers

Artisan chocolatiers have embraced chocolate aerators to experiment with different flavor profiles and textures. This experimentation has led to the creation of innovative products that showcase their craftsmanship and creativity.

Future Trends in Chocolate Production Technology

The Evolution of Chocolate Aerators

The chocolate production industry is constantly evolving, and so are the technologies that support it. Future trends in chocolate aerators may include:

1. Smart Technology Integration

As smart technology continues to advance, chocolate aerators are likely to incorporate IoT features that allow for real-time monitoring and adjustments. This integration can enhance precision and efficiency in the aeration process.

2. Sustainable Manufacturing Practices

With increasing consumer demand for sustainability, manufacturers may focus on producing eco-friendly chocolate aerators that minimize waste and energy consumption. This trend aligns with the broader movement toward sustainable production in the food industry.

3. Customization and Personalization

Future chocolate aerators may offer customizable features that allow manufacturers to tailor the aeration process to specific product requirements. This capability will enable greater creativity and innovation in chocolate production.

Frequently Asked Questions (FAQs)

1. What types of chocolate can be aerated using a chocolate aerator?

Chocolate aerators can be used with various types of chocolate, including dark, milk, and white chocolate, as well as different formulations for specific products.

2. How does aeration affect the shelf life of chocolate?

Aeration can improve the texture and flavor of chocolate but may also introduce air that can accelerate oxidation. Proper storage and packaging can help mitigate any negative effects on shelf life.

3. Are chocolate aerators easy to clean and maintain?

Most chocolate aerators are designed for easy cleaning and maintenance, with accessible components that simplify the process. Regular maintenance is essential for optimal performance.

4. Can I use a chocolate aerator for other applications besides chocolate production?

While primarily designed for chocolate, some aerators can also be used for applications involving other confections and creamy products, such as fillings or mousses.

5. How do I choose the right chocolate aerator for my business?

Consider factors like production capacity, material quality, energy efficiency, maintenance requirements, and manufacturer reputation when choosing a chocolate aerator for your business.

Conclusion

Incorporating a chocolate aerator from China into your chocolate production process can significantly enhance product quality, improve efficiency, and offer cost-effective solutions for manufacturers. With the ability to create lighter, creamier products and the flexibility to cater to diverse consumer preferences, chocolate aerators are becoming essential tools for chocolatiers and confectionery producers alike. By understanding the benefits and features of these machines, we can take our chocolate production to new heights, ensuring a competitive edge in an ever-evolving market.

Chocolate aerator from china