Unlocking the Secrets of the Best Sponge Cake Production Line

2025/07/15

When it comes to producing delicious sponge cakes, the quality of the production line plays a crucial role. The best sponge cake production line is designed to optimize efficiency, maintain product quality, and ensure consistency throughout the manufacturing process. Understanding the elements that contribute to an effective production line can significantly improve cake quality and customer satisfaction.

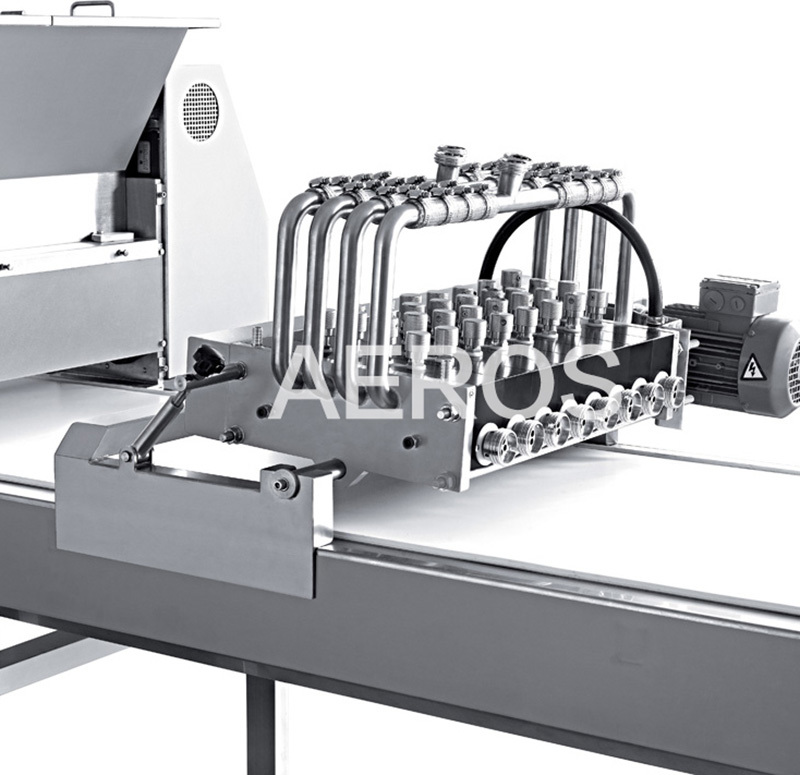

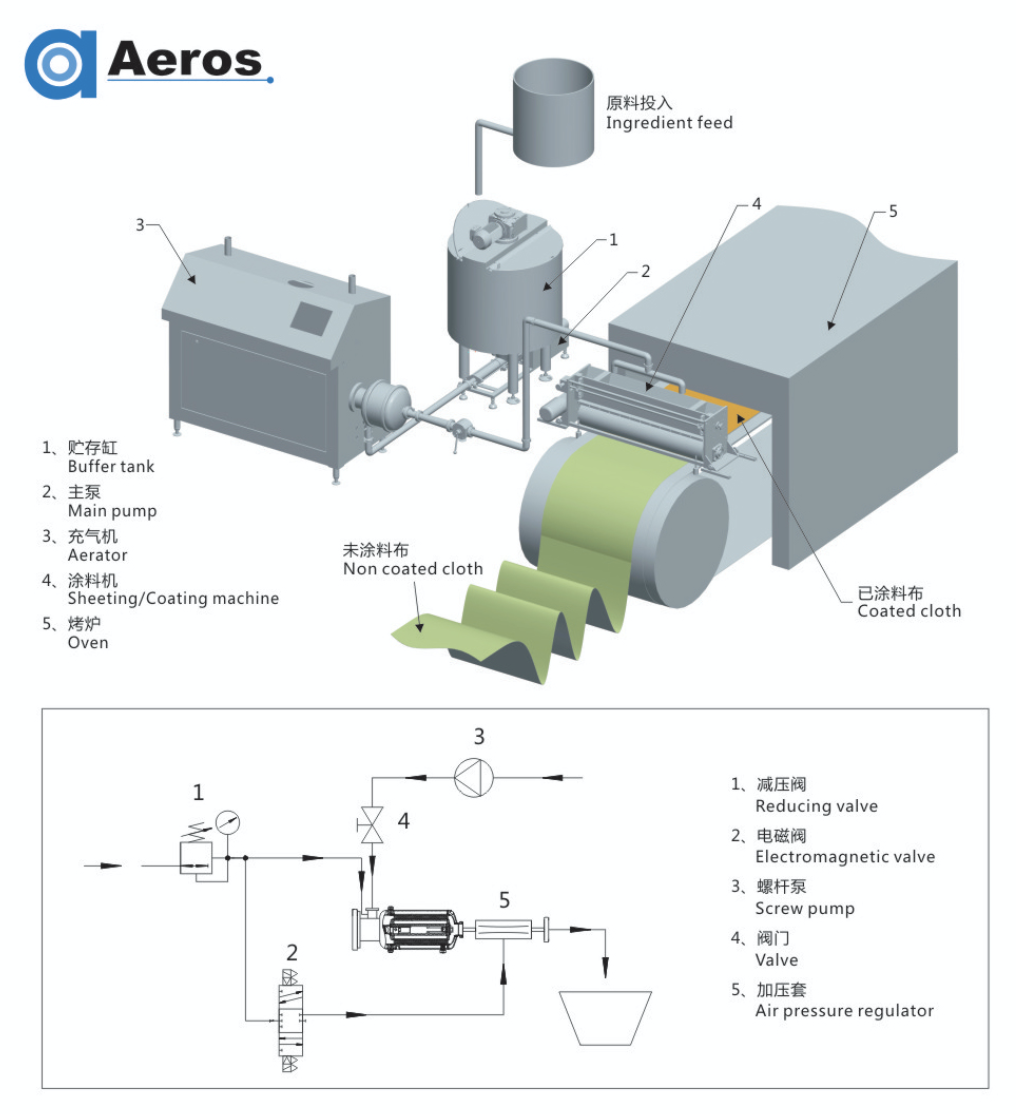

One of the key components of a top-notch sponge cake production line is its mixing technology. The mixing process is vital as it affects the texture and volume of the sponge cake. Advanced mixing machines, often equipped with precision controls, help achieve the correct aeration and incorporation of ingredients, resulting in a light and fluffy cake. This is particularly important for sponge cakes, where the balance of air and batter contributes to the final product's quality.

Another important aspect is the baking process. The best sponge cake production lines utilize state-of-the-art ovens that provide uniform heat distribution. This ensures that every batch of cakes is cooked evenly, minimizing the risk of undercooked or burnt products. Additionally, modern ovens may feature programmable settings that allow for precise temperature and timing control, catering to various recipes and cake sizes.

Cooling and packaging are also crucial stages in the sponge cake production process. After baking, cakes must be cooled appropriately to prevent moisture loss and maintain texture. A well-designed cooling system that integrates with the production line can enhance efficiency and product quality. Following cooling, automated packaging solutions are essential for preserving freshness and extending shelf life. Packaging equipment that utilizes breathable materials can further protect the sponge cake’s delicate structure while appealing to consumers.

Quality control is another integral part of the best sponge cake production line. Implementing robust quality assurance protocols throughout the production process ensures that every cake meets stringent quality standards. Regular testing of ingredients, as well as finished products, can help identify inconsistencies and facilitate improvements.

In addition to these mechanical components, the best sponge cake production lines are also increasingly incorporating automation and digital technologies. Automation can streamline processes, reduce labor costs, and improve accuracy, while digital monitoring systems can provide real-time data on production efficiency and quality metrics.

Ultimately, investing in the best sponge cake production line involves understanding the interplay of various technological advancements and traditional baking methods. By focusing on mixing, baking, cooling, packaging, and quality control, manufacturers can create high-quality sponge cakes that delight customers and stand out in a competitive market. In an ever-evolving food industry, staying informed about the latest production technologies can be the key to success in sponge cake manufacturing.

One of the key components of a top-notch sponge cake production line is its mixing technology. The mixing process is vital as it affects the texture and volume of the sponge cake. Advanced mixing machines, often equipped with precision controls, help achieve the correct aeration and incorporation of ingredients, resulting in a light and fluffy cake. This is particularly important for sponge cakes, where the balance of air and batter contributes to the final product's quality.

Another important aspect is the baking process. The best sponge cake production lines utilize state-of-the-art ovens that provide uniform heat distribution. This ensures that every batch of cakes is cooked evenly, minimizing the risk of undercooked or burnt products. Additionally, modern ovens may feature programmable settings that allow for precise temperature and timing control, catering to various recipes and cake sizes.

Cooling and packaging are also crucial stages in the sponge cake production process. After baking, cakes must be cooled appropriately to prevent moisture loss and maintain texture. A well-designed cooling system that integrates with the production line can enhance efficiency and product quality. Following cooling, automated packaging solutions are essential for preserving freshness and extending shelf life. Packaging equipment that utilizes breathable materials can further protect the sponge cake’s delicate structure while appealing to consumers.

Quality control is another integral part of the best sponge cake production line. Implementing robust quality assurance protocols throughout the production process ensures that every cake meets stringent quality standards. Regular testing of ingredients, as well as finished products, can help identify inconsistencies and facilitate improvements.

In addition to these mechanical components, the best sponge cake production lines are also increasingly incorporating automation and digital technologies. Automation can streamline processes, reduce labor costs, and improve accuracy, while digital monitoring systems can provide real-time data on production efficiency and quality metrics.

Ultimately, investing in the best sponge cake production line involves understanding the interplay of various technological advancements and traditional baking methods. By focusing on mixing, baking, cooling, packaging, and quality control, manufacturers can create high-quality sponge cakes that delight customers and stand out in a competitive market. In an ever-evolving food industry, staying informed about the latest production technologies can be the key to success in sponge cake manufacturing.

best Sponge cake Production line

Previous Page