Unlocking the Secrets of Chocolate Enrobing Machines: A Comprehensive Guide

2025/07/07

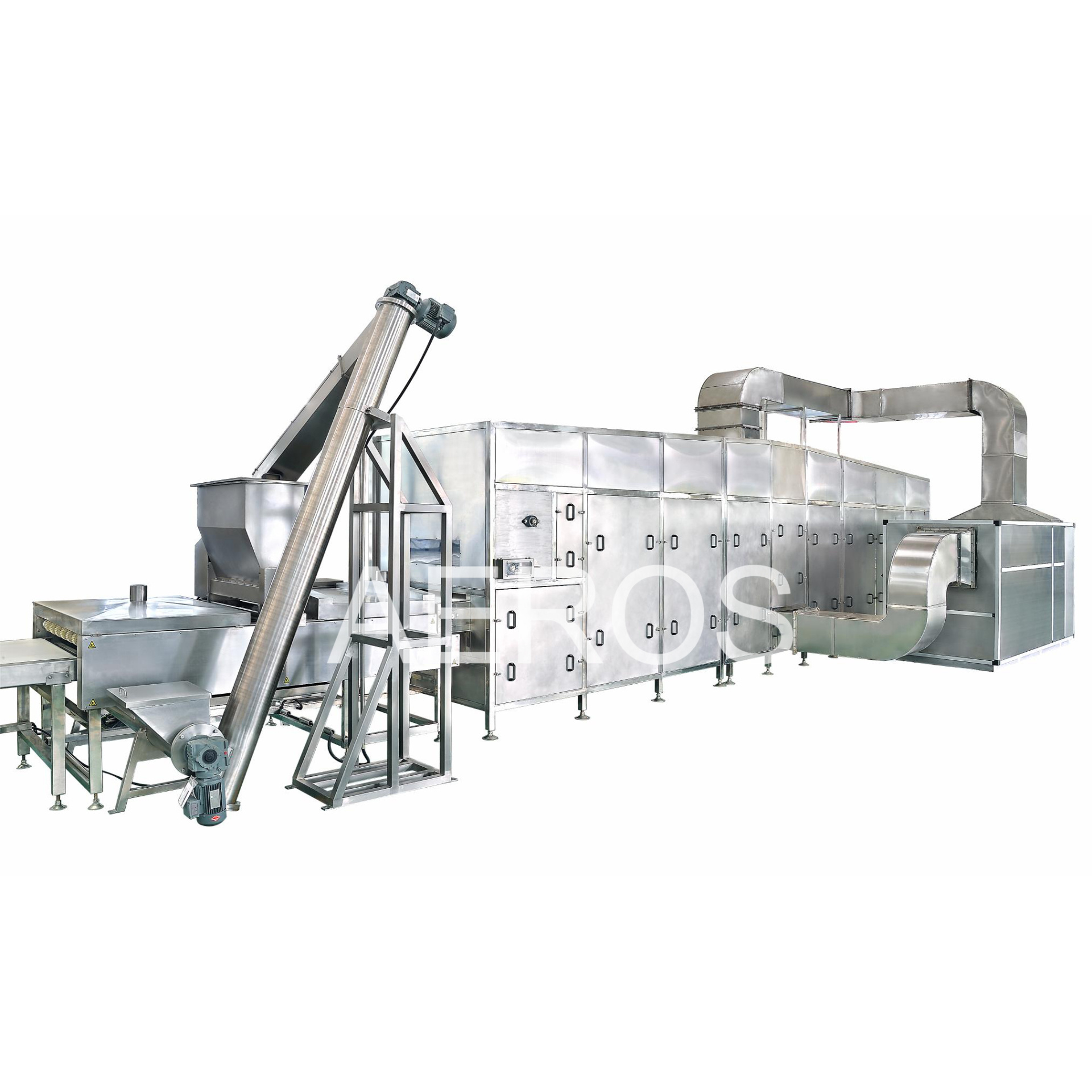

Chocolate enrobing machines play a pivotal role in the snack food manufacturing industry, particularly when it comes to creating delectable chocolate-coated products. These specialized machines are designed to coat various food items, such as biscuits, nuts, and confections, with a layer of delicious chocolate, providing both aesthetic appeal and enhanced flavor.

One of the primary advantages of using a chocolate enrobing machine is the consistency it delivers. Manual coating processes can often lead to uneven layers, resulting in a product that may not meet consumer expectations. In contrast, enrobing machines ensure that each item is uniformly coated, which not only improves the visual presentation but also standardizes the taste experience for consumers.

The functionality of chocolate enrobing machines typically includes several crucial components. A melting tank heats the chocolate to the ideal temperature, ensuring it remains fluid for proper coating. The enrobing section usually features a conveyor belt that transports the items through the cascading chocolate curtain, allowing for an even distribution of chocolate. Additionally, some machines are equipped with cooling tunnels to set the chocolate quickly, enhancing the production rate and reducing wait times.

Efficiency is another compelling reason to consider investing in a chocolate enrobing machine. By automating the coating process, manufacturers can significantly increase output, meet consumer demand, and minimize labor costs. This automation also reduces the chances of human error, leading to fewer product inconsistencies and higher overall quality.

Furthermore, modern chocolate enrobing machines come with various customizable features, allowing manufacturers to adapt to different production needs. Options such as adjustable speed settings, temperature controls, and varying enrobing thickness enable producers to tailor their processes and optimize the final product to their specifications. This flexibility can be crucial for companies looking to innovate or expand their product lines.

It's also worth noting that the chocolate enrobing process can extend the shelf life of certain products. The chocolate coating acts as a barrier, protecting the underlying food item from exposure to air and moisture, which can lead to spoilage. This protective layer can be particularly advantageous for snacks that are prone to staleness or degradation over time.

In conclusion, chocolate enrobing machines are invaluable assets within the food processing industry. They streamline production, ensure product consistency, and enable manufacturers to create high-quality, visually appealing chocolate-coated snacks. For anyone involved in the snack food sector, understanding the benefits and functionalities of chocolate enrobing machines can be a game-changer in their production strategy.

One of the primary advantages of using a chocolate enrobing machine is the consistency it delivers. Manual coating processes can often lead to uneven layers, resulting in a product that may not meet consumer expectations. In contrast, enrobing machines ensure that each item is uniformly coated, which not only improves the visual presentation but also standardizes the taste experience for consumers.

The functionality of chocolate enrobing machines typically includes several crucial components. A melting tank heats the chocolate to the ideal temperature, ensuring it remains fluid for proper coating. The enrobing section usually features a conveyor belt that transports the items through the cascading chocolate curtain, allowing for an even distribution of chocolate. Additionally, some machines are equipped with cooling tunnels to set the chocolate quickly, enhancing the production rate and reducing wait times.

Efficiency is another compelling reason to consider investing in a chocolate enrobing machine. By automating the coating process, manufacturers can significantly increase output, meet consumer demand, and minimize labor costs. This automation also reduces the chances of human error, leading to fewer product inconsistencies and higher overall quality.

Furthermore, modern chocolate enrobing machines come with various customizable features, allowing manufacturers to adapt to different production needs. Options such as adjustable speed settings, temperature controls, and varying enrobing thickness enable producers to tailor their processes and optimize the final product to their specifications. This flexibility can be crucial for companies looking to innovate or expand their product lines.

It's also worth noting that the chocolate enrobing process can extend the shelf life of certain products. The chocolate coating acts as a barrier, protecting the underlying food item from exposure to air and moisture, which can lead to spoilage. This protective layer can be particularly advantageous for snacks that are prone to staleness or degradation over time.

In conclusion, chocolate enrobing machines are invaluable assets within the food processing industry. They streamline production, ensure product consistency, and enable manufacturers to create high-quality, visually appealing chocolate-coated snacks. For anyone involved in the snack food sector, understanding the benefits and functionalities of chocolate enrobing machines can be a game-changer in their production strategy.

Chocolate Enrobing Machine

Previous Page