Unlocking Efficiency: The Role of a Continuous Aerator in Modern Manufacturing

2025/07/04

Unlocking Efficiency: The Role of a Continuous Aerator in Modern Manufacturing

In today's competitive manufacturing landscape, companies strive for innovative solutions that enhance productivity and quality. One such solution is the **continuous aerator**, a vital component in various manufacturing processes. This article explores the significant role continuous aerators play in modern manufacturing, examining their benefits, applications, and the technology driving their efficiency. With a focus on operational excellence, we will uncover how continuous aerators contribute to streamlined workflows and superior product outcomes.

Table of Contents

- What is a Continuous Aerator?

- The Importance of Continuous Aerators in Manufacturing

- Benefits of Using Continuous Aerators in Production

- Applications of Continuous Aerators in Various Industries

- How Do Continuous Aerators Work?

- Technological Advancements in Continuous Aeration

- Future Trends in Continuous Aeration and Manufacturing

- Frequently Asked Questions (FAQs)

What is a Continuous Aerator?

A continuous aerator is an advanced piece of equipment designed to introduce and mix air into liquids or slurries continuously. Unlike batch aerators, which operate intermittently, continuous aerators ensure a steady flow of aeration, enhancing efficiency and consistency in manufacturing processes. These aerators are commonly used in industries such as food and beverage, wastewater treatment, and chemical manufacturing, where precise oxygenation and mixing are critical for optimal product quality.

The Importance of Continuous Aerators in Manufacturing

The significance of continuous aerators in manufacturing cannot be overstated. They provide a range of advantages that contribute to overall process efficiency. By ensuring consistent oxygen levels in various mediums, these devices play a crucial role in promoting chemical reactions, enhancing product quality, and reducing processing times. This leads to significant cost savings and increased throughput, making continuous aerators indispensable for modern manufacturing operations.

Enhancing Production Efficiency

Continuous aerators facilitate uninterrupted production flows, optimizing manufacturing processes. This efficiency reduces downtime associated with batch processing, allowing manufacturers to meet growing market demands and maintain a competitive edge.

Improving Product Quality

By maintaining optimal oxygen levels and ensuring thorough mixing, continuous aerators help prevent inconsistencies in product quality. This is particularly important in industries such as brewing and dairy, where the quality of the final product is directly linked to the aeration process.

Reducing Operational Costs

Continuous aerators can significantly lower operational costs by minimizing energy consumption and waste. Their efficiency allows manufacturers to use fewer resources while achieving higher output, contributing to a more sustainable manufacturing model.

Benefits of Using Continuous Aerators in Production

The benefits of implementing continuous aerators in manufacturing processes are multifaceted. Here are some key advantages:

1. Continuous Operation

Unlike traditional batch systems, continuous aerators operate without interruptions. This feature is essential for processes requiring constant aeration, leading to increased production rates and reduced labor costs.

2. Enhanced Mixing Capabilities

Continuous aerators excel at providing uniform mixing throughout the liquid or slurry, ensuring consistent product quality. This capability is critical in applications where precise ingredient ratios are essential.

3. Improved Control Over Processes

Continuous aerators allow for better control over aeration parameters such as flow rate and oxygen levels. This precise control translates to enhanced product quality and consistency, which is vital in industries like pharmaceuticals and food production.

4. Lower Maintenance Requirements

These systems are often designed to be more robust and require less maintenance than traditional aeration systems. This reliability reduces downtime and associated costs, contributing to a more efficient manufacturing environment.

5. Versatility Across Industries

Continuous aerators can be tailored to suit various applications, making them a versatile solution for multiple industries. Whether in food processing, wastewater treatment, or chemical manufacturing, continuous aerators can meet diverse needs.

Applications of Continuous Aerators in Various Industries

Continuous aerators find extensive use across multiple sectors, each with unique requirements and applications:

1. Food and Beverage Industry

In the food and beverage sector, continuous aerators are essential for fermentation processes, such as brewing beer and producing yogurt. Their ability to maintain optimal oxygen levels ensures consistent flavor profiles and product quality.

2. Wastewater Treatment

Continuous aerators play a crucial role in wastewater treatment by promoting the aerobic digestion of organic materials. This process helps reduce pollutants and improve water quality before discharge into natural water bodies.

3. Chemical Manufacturing

In chemical manufacturing, continuous aerators are used to facilitate reactions requiring specific oxygen levels. This controlled environment enhances reaction rates, leading to higher yields and improved product quality.

4. Pharmaceutical Manufacturing

Continuous aeration is vital in pharmaceutical manufacturing to ensure consistent quality in the production of active ingredients. Maintaining precise aeration conditions helps avoid contamination and ensures product efficacy.

5. Aquaculture

Continuous aerators are also utilized in aquaculture to maintain oxygen levels in fish farming. By ensuring optimal conditions for aquatic life, these systems contribute to healthier and faster-growing fish stocks.

How Do Continuous Aerators Work?

Understanding the mechanics of continuous aerators provides insight into their effectiveness in manufacturing processes. These systems typically consist of the following components:

1. Air Supply System

The air supply system is responsible for introducing air into the liquid or slurry. This can include blowers, compressors, or diffusers designed to deliver air at the required pressure and flow rate.

2. Mixing Chamber

The mixing chamber is where air and liquid interact. Continuous aerators often feature innovative designs that enhance mixing efficiency, ensuring uniform distribution of oxygen throughout the medium.

3. Control Systems

Advanced control systems monitor and adjust aeration parameters in real-time. These systems ensure that optimal conditions are maintained, allowing for precise control over the aeration process.

4. Discharge Mechanism

After aeration, the treated liquid or slurry is discharged for further processing or use. This seamless transition is essential for maintaining continuous production flows.

Technological Advancements in Continuous Aeration

Recent advancements in technology have further enhanced the efficiency of continuous aerators:

1. Smart Aeration Systems

Smart aeration systems utilize IoT technology to monitor and optimize aeration processes remotely. This capability allows for real-time adjustments based on changing production conditions, enhancing overall efficiency.

2. Energy-Efficient Designs

Modern continuous aerators are designed with energy efficiency in mind. Innovations such as variable frequency drives and advanced motor technologies help reduce energy consumption while maintaining performance.

3. Improved Materials

Advances in material science have led to the development of more durable components, reducing wear and tear and extending the lifespan of continuous aerators. This reliability contributes to lower maintenance costs.

4. Automation and Integration

Continuous aerators are increasingly being integrated with other manufacturing processes, enabling seamless automation. This integration enhances production efficiency and reduces the risk of human error.

Future Trends in Continuous Aeration and Manufacturing

As the manufacturing sector continues to evolve, several trends are likely to shape the future of continuous aeration:

1. Increased Demand for Sustainable Solutions

Manufacturers are increasingly focused on sustainability. Continuous aerators that minimize energy consumption and waste will become more prevalent as companies seek to reduce their environmental footprint.

2. Enhanced Customization

Future continuous aerators are expected to offer greater customization options, allowing manufacturers to tailor aeration systems to their specific processes and requirements.

3. Integration of Artificial Intelligence

Artificial intelligence will play a role in optimizing aeration processes, allowing for predictive maintenance and real-time adjustments based on data analysis. This integration will enhance overall efficiency and reliability.

Frequently Asked Questions (FAQs)

1. What industries benefit from continuous aerators?

Continuous aerators are widely used in various industries, including food and beverage, wastewater treatment, chemical manufacturing, pharmaceuticals, and aquaculture.

2. How do continuous aerators improve product quality?

By maintaining optimal oxygen levels and ensuring consistent mixing, continuous aerators help prevent inconsistencies in product quality, leading to better outcomes in manufacturing processes.

3. Are continuous aerators expensive to operate?

Continuous aerators can lead to lower operational costs by minimizing energy consumption and waste. Their efficiency often offsets initial investment costs over time.

4. How do I choose the right continuous aerator for my needs?

Choosing the right continuous aerator depends on several factors, including the type of application, required oxygen levels, and specific production requirements. Consulting with manufacturers can provide valuable insights.

5. What are the maintenance requirements for continuous aerators?

Continuous aerators are designed for low maintenance, but regular checks on components such as the air supply system and mixing chamber are essential to ensure optimal performance.

Conclusion

In conclusion, continuous aerators play a transformative role in modern manufacturing, enhancing efficiency, product quality, and sustainability. As industries continue to adopt advanced technologies, the integration of continuous aerators will prove vital in meeting the demands of an ever-evolving market. By understanding their functionality and benefits, manufacturers can harness the power of continuous aeration to drive operational excellence and remain competitive in their respective fields. Investing in continuous aerators not only boosts production efficiency but also paves the way for a sustainable manufacturing future.

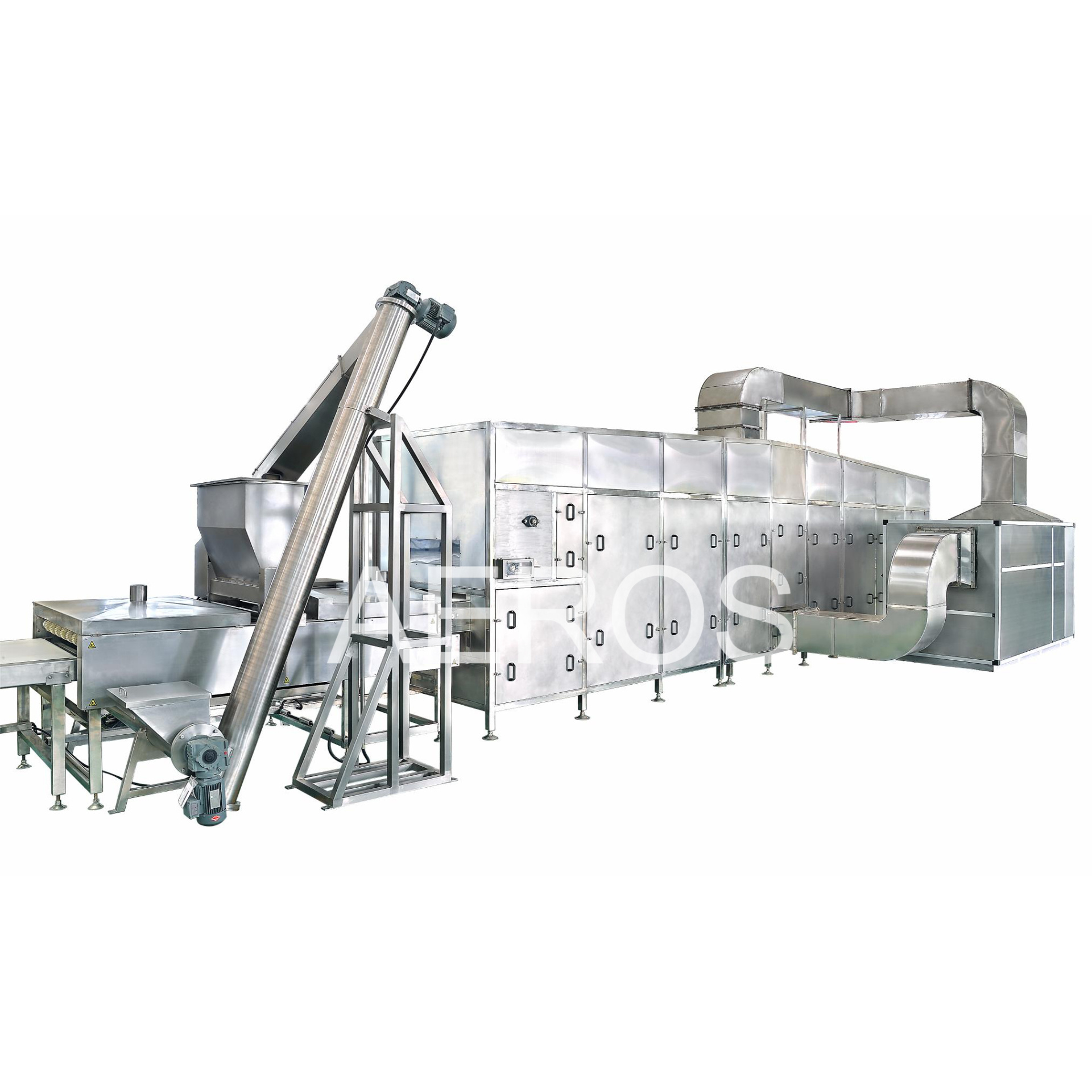

Continuous aerator