Transform Your Candy Business with an Efficient Marshmallow Production Line

2025/07/06

Transform Your Candy Business with an Efficient Marshmallow Production Line

Table of Contents

- 1. Introduction to Marshmallow Production Lines

- 2. Importance of Efficient Machinery in Candy Manufacturing

- 3. Benefits of Upgrading to Modern Marshmallow Production Lines

- 4. Key Features of an Effective Marshmallow Production Line

- 5. Understanding the Marshmallow Production Process

- 5.1 Ingredient Mixing and Preparation

- 5.2 Cooking and Whipping

- 5.3 Forming and Cutting

- 5.4 Packaging and Quality Control

- 6. Choosing the Right Marshmallow Production Line for Your Business

- 7. Cost Considerations for Marshmallow Production Lines

- 8. Future Trends in Marshmallow Production

- 9. Frequently Asked Questions

1. Introduction to Marshmallow Production Lines

In the candy manufacturing industry, **marshmallows** hold a unique place. They are not only popular as standalone treats but also serve as key ingredients in various confections, from s'mores to festive desserts. An efficient **marshmallow production line** can significantly enhance your candy business by streamlining operations and improving product quality. This article delves into the essential aspects of marshmallow production lines, providing insights on how they can revolutionize your manufacturing process.

2. Importance of Efficient Machinery in Candy Manufacturing

The candy industry is highly competitive, and efficiency is crucial for staying ahead. Investing in advanced machinery like a marshmallow production line can mean the difference between marginal profits and substantial gains. Here are some reasons why efficient machinery is vital:

- **Consistency in Quality**: Modern production lines ensure uniformity in product quality, meeting consumer expectations and regulatory standards.

- **Increased Output**: Automated systems can significantly boost production rates, allowing businesses to meet higher demand without sacrificing quality.

- **Cost-Effectiveness**: Advanced machinery reduces labor costs and minimizes material waste, thus enhancing overall profitability.

- **Flexibility**: With the right equipment, manufacturers can easily switch between different flavors and formulations to meet market trends.

3. Benefits of Upgrading to Modern Marshmallow Production Lines

Upgrading to a modern marshmallow production line offers numerous advantages:

- **Enhanced Production Speed**: Faster production cycles lead to quicker turnaround times, allowing businesses to respond to market demands efficiently.

- **Improved Safety Standards**: Modern machines are designed with safety features that protect workers and ensure compliance with food safety regulations.

- **Better Resource Management**: Automated systems optimize ingredient usage, reducing waste and lowering costs.

- **Customizable Settings**: Many modern lines allow for customization, enabling manufacturers to create unique marshmallow products tailored to specific customer preferences.

4. Key Features of an Effective Marshmallow Production Line

When selecting a marshmallow production line, consider the following key features:

- **High-Quality Mixers**: Effective mixing is crucial for achieving the desired texture and flavor in marshmallows. Look for machines that offer precise control over mixing times and speeds.

- **Temperature Control Systems**: Accurate temperature regulation during cooking is essential for producing marshmallows with the right consistency.

- **Automated Cutting and Forming Tools**: Machines that provide precise cutting and forming capabilities help maintain product quality and reduce labor costs.

- **Efficient Packaging Solutions**: Streamlined packaging systems can significantly enhance productivity, ensuring that products are ready for distribution quickly.

5. Understanding the Marshmallow Production Process

To fully appreciate the benefits of a marshmallow production line, it’s important to understand the production process. This process typically involves multiple stages:

5.1 Ingredient Mixing and Preparation

The initial stage involves mixing ingredients such as sugar, corn syrup, and gelatin. The quality of the mixing process is critical, as it affects the final texture and taste of the marshmallow. Automated mixers ensure that all ingredients are thoroughly blended and aerated.

5.2 Cooking and Whipping

Once the ingredients are mixed, they are heated to a specific temperature. This cooking phase is crucial for dissolving the sugar and activating the gelatin. After cooking, the mixture is whipped to incorporate air, creating the light and fluffy texture characteristic of marshmallows.

5.3 Forming and Cutting

Following the whipping stage, the marshmallow mixture is poured into molds or onto a conveyor belt, where it is cut into the desired shapes. This step can be automated to ensure uniformity and efficiency.

5.4 Packaging and Quality Control

The final stage involves packaging the marshmallows for distribution. Automated packaging systems can significantly speed up this process while ensuring that the product remains fresh and protected.

6. Choosing the Right Marshmallow Production Line for Your Business

Selecting the right marshmallow production line is a critical decision that can impact your business's success. Consider the following factors:

- **Production Capacity**: Assess your current and future production needs to choose a machine that can handle your requirements.

- **Budget**: Evaluate the costs associated with the machinery and how it aligns with your financial goals.

- **Customization Options**: Determine if the production line can be tailored to meet your specific needs for flavors, sizes, and packaging.

- **Supplier Reputation**: Research manufacturers who offer reliable support and maintenance services.

7. Cost Considerations for Marshmallow Production Lines

Investing in a marshmallow production line is a significant financial commitment. Key factors that influence the costs include:

- **Initial Purchase Price**: The cost of the machinery itself can vary greatly depending on features and capabilities.

- **Maintenance and Upkeep**: Regular maintenance is essential for longevity, and these costs should be factored into your budget.

- **Training and Labor**: Allocate funds for employee training to ensure that your team can operate the machinery efficiently.

- **Operational Costs**: Consider the ongoing costs of ingredients, utilities, and labor when evaluating your profit margins.

8. Future Trends in Marshmallow Production

The candy manufacturing landscape is constantly evolving, and staying ahead of trends is vital for success. Some future trends in marshmallow production include:

- **Health-Conscious Products**: As consumers become more health-conscious, there is a growing demand for low-calorie, organic, and allergen-free marshmallows.

- **Sustainable Practices**: Environmentally-friendly production methods and packaging solutions are becoming increasingly important to consumers.

- **Technological Advancements**: Innovations in automation and artificial intelligence will continue to enhance production efficiency and product quality.

9. Frequently Asked Questions

What is a marshmallow production line?

A marshmallow production line is a series of automated machines designed to efficiently produce marshmallows from mixing to packaging.

How does upgrading my production line benefit my business?

Upgrading to a modern marshmallow production line can improve product quality, increase production speed, and reduce costs, ultimately leading to higher profits.

What should I consider when choosing a marshmallow production line?

Consider production capacity, budget, customization options, and the reputation of the supplier when selecting a production line.

Are there sustainable options available for marshmallow production?

Yes, many manufacturers now offer machines designed for sustainable practices, including energy-efficient operations and eco-friendly packaging solutions.

How can I ensure the quality of my marshmallows?

Implementing rigorous quality control measures during each stage of the production process, from ingredient mixing to packaging, will help maintain high product quality.

Conclusion

Investing in an efficient marshmallow production line can profoundly impact your candy business. By enhancing production speed, ensuring product quality, and allowing for customization, you position your business for success in a competitive market. Embrace the future of candy manufacturing by upgrading your equipment and adopting innovative practices. The right marshmallow production line will not only streamline your operations but also open up new possibilities for creativity and profitability in your candy offerings.

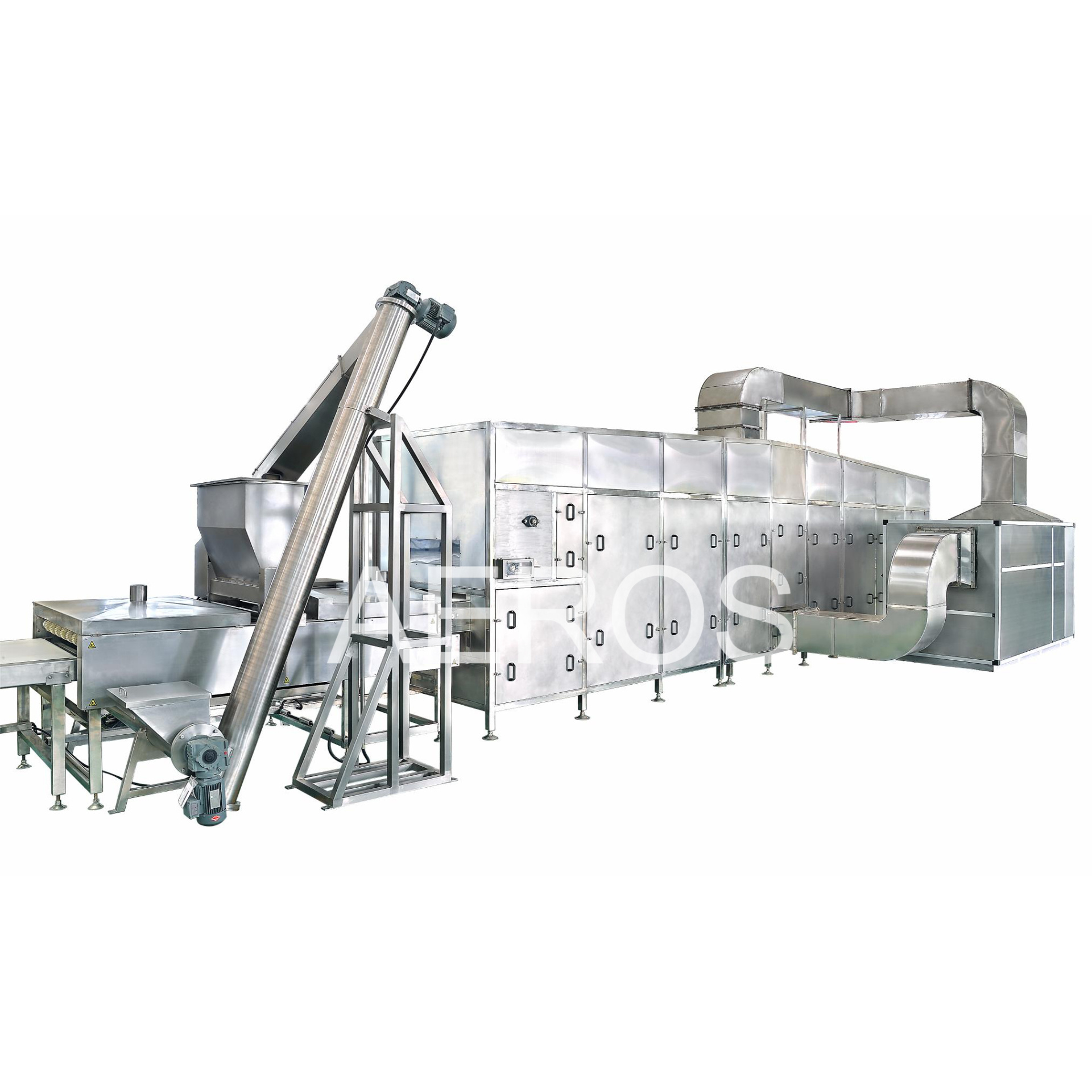

Marshmallow Production Line

Previous Page