Revolutionizing Dairy: What You Need to Know About Cream Production Lines

2025/06/22

Revolutionizing Dairy: What You Need to Know About Cream Production Lines

Table of Contents

- Understanding Cream Production

- Importance of Cream Production Lines in Dairy

- Key Components of Cream Production Lines

- Technology in Cream Production

- Benefits of Modern Cream Production Lines

- Sustainability in Dairy Processing

- Choosing the Right Cream Production Line for Your Business

- Frequently Asked Questions

- Conclusion

Understanding Cream Production

Cream production is a critical aspect of the dairy industry, where the primary goal is to separate cream from milk. The process is not only vital for producing various dairy products like butter and cheese, but it also plays a significant role in determining the overall quality and flavor of these products. Understanding the nuances of cream production helps stakeholders in the dairy industry optimize their processes and enhance the quality of their offerings.

Cream is a high-fat layer that rises to the top of milk during the milk separation process. It contains valuable nutrients and contributes to the rich texture and taste of dairy products. The production of cream involves several stages, including pasteurization, homogenization, and sometimes, standardization to achieve specific fat contents. Effective management of these processes is essential for maintaining product quality and meeting consumer demands.

Importance of Cream Production Lines in Dairy

Modern cream production lines are essential for any dairy processing facility. They streamline the production process, enhance efficiency, and ensure product quality. With the growing consumer demand for high-quality dairy products, investing in a state-of-the-art cream production line can provide a competitive edge in the market.

1. **Increased Efficiency**: Automated cream production lines drastically reduce the time and labor required for cream production. They enable continuous processing, reducing downtime between batches and ultimately increasing output.

2. **Consistent Quality**: Advanced technology in cream production lines ensures consistent quality in the final product. Automated systems can monitor various parameters, such as temperature and fat content, in real-time, allowing for immediate adjustments as needed.

3. **Cost Reduction**: By optimizing processes and reducing waste, modern cream production lines contribute to significant cost savings over time. This efficiency helps in keeping production costs low while maintaining high-quality standards.

4. **Compliance and Safety**: Dairy production is subject to stringent regulations regarding hygiene and food safety. Modern cream production lines are designed with these regulations in mind, ensuring that products are safe and compliant with industry standards.

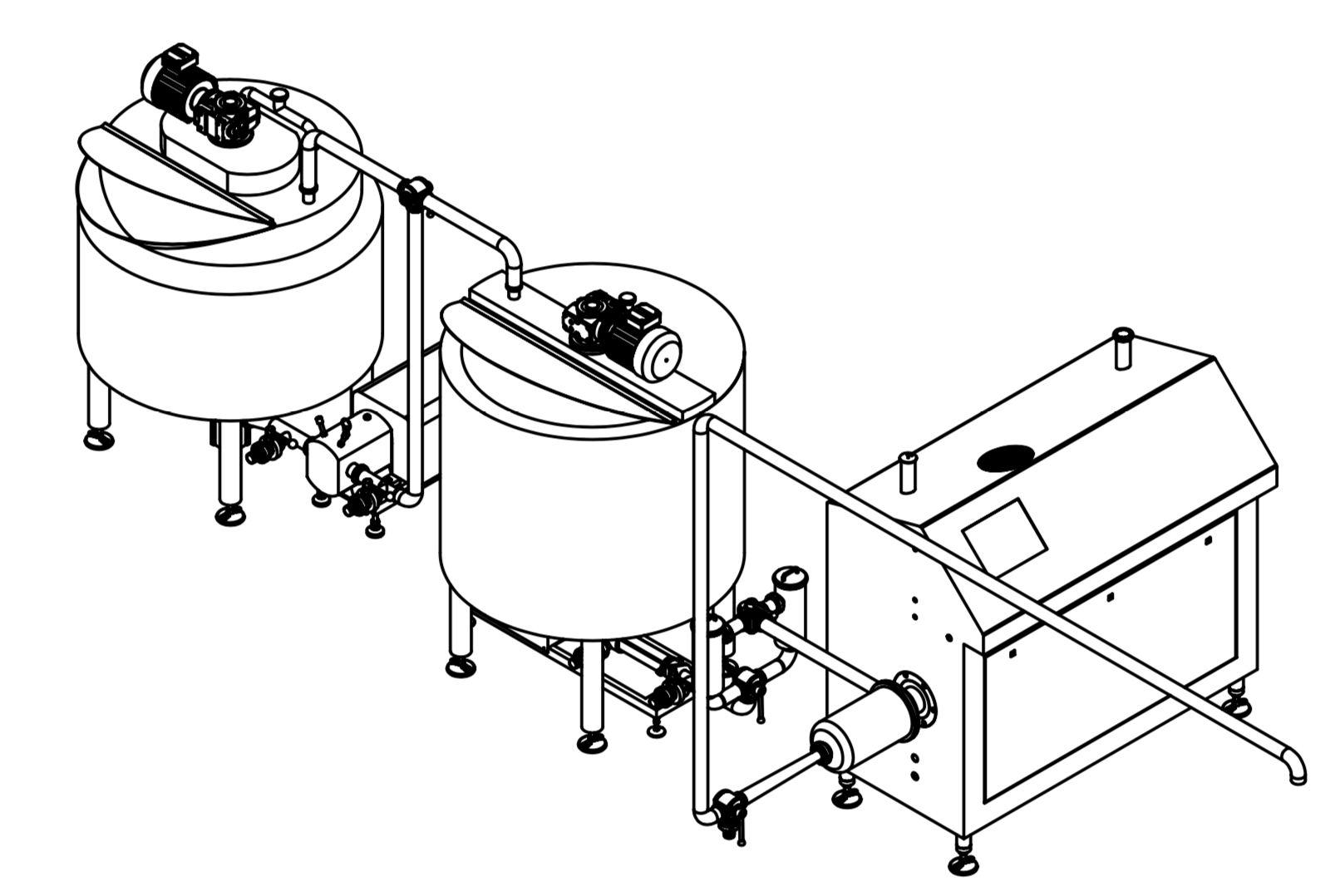

Key Components of Cream Production Lines

A well-designed cream production line comprises several key components, each playing a critical role in the overall process. These components include:

1. Milk Reception and Storage

The cream production process begins with the reception and storage of raw milk. Raw milk must be stored in refrigerated tanks to maintain freshness and prevent spoilage. Quality control measures are essential during this stage to ensure the milk meets industry standards.

2. Pasteurization Equipment

Pasteurization is a crucial step in cream production. It involves heating the milk to kill harmful bacteria and extend shelf life. High-efficiency pasteurizers ensure that the milk is treated uniformly, maintaining its nutritional quality while ensuring safety.

3. Separation Units

The separation unit is where the actual cream is separated from the milk. Centrifugal separators are commonly used due to their efficiency in separating cream based on density. The design of these units impacts the yield and quality of the cream produced.

4. Homogenization Equipment

Homogenization is essential for achieving a uniform fat distribution in the cream. Homogenizers apply high pressure to break down fat globules, preventing cream from rising to the top in packaged products. This step is crucial for maintaining the desired texture and mouthfeel of the final products.

5. Standardization Systems

Standardization systems ensure that the cream produced meets specific fat content requirements. This is particularly important for manufacturers producing different dairy products that require varying fat levels.

6. Cooling and Storage Systems

Once the cream has been produced, it must be cooled rapidly to prevent spoilage and maintain freshness. Effective cooling and storage systems are vital for extending the shelf life of cream products.

7. Packaging Solutions

Packaging is the final step in the cream production line. Modern packaging solutions not only protect the product but also enhance its market appeal. Innovative packaging technologies have been developed to extend shelf life and improve consumer convenience.

Technology in Cream Production

Technological advancements have significantly impacted cream production lines, making them more efficient and reliable. Here are some key technologies driving innovation in the dairy industry:

1. Automation and Control Systems

Automation has revolutionized cream production, allowing for real-time monitoring and control of processes. Advanced control systems enable operators to adjust parameters remotely, ensuring optimal conditions for cream production.

2. IoT Integration

The Internet of Things (IoT) has found its way into dairy production, enabling seamless communication between machines. IoT devices can collect data on production processes, helping in predictive maintenance and preventing breakdowns.

3. Energy-Efficient Technologies

With sustainability becoming a priority, energy-efficient technologies are now integral to modern cream production lines. These technologies reduce energy consumption, lower operational costs, and contribute to a smaller environmental footprint.

4. Data Analytics

Data analytics plays a crucial role in optimizing production lines. Analyzing data from production processes helps in identifying inefficiencies and improving overall production quality.

Benefits of Modern Cream Production Lines

The move towards modern cream production lines offers numerous benefits for dairy manufacturers:

1. Enhanced Product Quality

Quality control measures integrated into modern production lines ensure that the final products meet the highest standards. Consistent fat content and texture improve consumer satisfaction.

2. Increased Production Capacity

With automation and streamlined processes, dairy manufacturers can significantly increase their production capacity. This is vital for meeting growing market demands.

3. Improved Traceability

Modern production lines often include traceability features, allowing manufacturers to track products through every stage of production. This transparency is crucial for quality assurance and recalls if necessary.

4. Competitive Advantage

Investing in innovative cream production lines can set a company apart from its competitors. The ability to produce high-quality products efficiently can attract more customers and increase market share.

Sustainability in Dairy Processing

Sustainability is a major concern in the dairy industry. Modern cream production lines are designed to minimize waste and reduce environmental impact. Here are some sustainable practices being adopted:

1. Waste Reduction

Efficient production lines focus on minimizing waste during the cream production process. This includes optimizing the use of raw materials and reusing by-products where possible.

2. Eco-Friendly Packaging

Sustainable packaging solutions are increasingly being utilized to reduce plastic waste. Biodegradable and recyclable materials are becoming more common in dairy product packaging.

3. Water Conservation

Water is a vital resource in dairy processing. Modern production lines incorporate water-saving technologies to ensure that water use is minimized without compromising product quality.

Choosing the Right Cream Production Line for Your Business

Selecting the appropriate cream production line is crucial for ensuring operational efficiency and product quality. Consider the following factors:

1. Production Volume

Assess your production needs to determine the volume of cream you need to produce. This will help you choose a line that can handle your specific requirements.

2. Flexibility and Scalability

Choose a production line that can adapt to changes in demand. Scalability is essential for accommodating future growth in production.

3. Maintenance and Support

Evaluate the maintenance requirements of the production line and the level of support provided by the manufacturer. A reliable support system is crucial for minimizing downtime.

4. Budget and Cost Efficiency

While it’s important to invest in high-quality equipment, ensure that the production line fits within your budget. Analyze the cost-efficiency of the line in terms of energy use, labor, and maintenance.

Frequently Asked Questions

1. What is the role of pasteurization in cream production?

Pasteurization is essential for eliminating harmful bacteria in raw milk, ensuring the safety and longevity of the cream produced.

2. How can automation improve cream production efficiency?

Automation allows for real-time monitoring and control of production processes, reducing labor costs and increasing output efficiency.

3. What are the environmental benefits of modern cream production lines?

Modern lines focus on reducing waste, conserving water, and utilizing sustainable packaging, contributing to a lower environmental impact.

4. How do I determine the right fat content for my cream products?

The right fat content varies depending on the end product. Manufacturers should conduct market research to identify consumer preferences and adjust their production processes accordingly.

5. What advancements are driving innovation in dairy processing technology?

Key advancements include IoT integration, data analytics, and energy-efficient technologies, all of which contribute to enhanced efficiency and product quality.

Conclusion

The evolution of cream production lines is a testament to the dairy industry’s commitment to quality, efficiency, and sustainability. By investing in modern technologies and adopting innovative practices, dairy manufacturers can ensure they meet growing consumer demands while reducing their environmental footprint. Understanding the components and benefits of these production lines enables stakeholders to make informed decisions that will lead to a brighter, more prosperous future for the dairy industry.

Cream production line

Previous Page