Exploring the Benefits of Using an Advanced Muffin Production Line: Revolutionizing Food Processing Efficiency

2025/06/18

Exploring the Benefits of Using an Advanced Muffin Production Line

Table of Contents

- 1. Introduction to Muffin Production Lines

- 2. Technology Advancements in Muffin Production

- 3. Key Benefits of Using an Advanced Muffin Production Line

- 3.1 Increased Efficiency and Productivity

- 3.2 Enhanced Product Quality

- 3.3 Scalability for Growing Businesses

- 3.4 Cost-Effectiveness and Resource Management

- 3.5 Sustainability in Muffin Production

- 4. Key Components of an Advanced Muffin Production Line

- 5. Current Trends in Muffin Production Technology

- 6. Case Studies: Successful Muffin Production Implementations

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Muffin Production Lines

In today's fast-paced food industry, the **muffin production line** plays a crucial role in ensuring efficiency, consistency, and high-quality output. With increasing consumer demand for muffins and baked goods, manufacturers must adopt advanced production technologies to stay competitive. This article delves into the myriad benefits of implementing an advanced muffin production line, underscoring its relevance in modern food processing.

2. Technology Advancements in Muffin Production

The evolution of muffin production technology has transformed how these delightful treats are manufactured. Innovations such as **automated mixing systems**, **precision baking equipment**, and **advanced packaging solutions** have paved the way for higher output rates and improved product consistency.

Automated systems reduce human error and streamline processes, allowing for faster production times. Moreover, the integration of **smart technologies** has enabled real-time monitoring and control of the production process, enhancing operational efficiency and product quality.

3. Key Benefits of Using an Advanced Muffin Production Line

Investing in an advanced muffin production line yields numerous advantages for manufacturers. Let's explore these benefits in detail.

3.1 Increased Efficiency and Productivity

One of the primary benefits of an advanced muffin production line is the significant boost in **efficiency and productivity**. Automated processes minimize manual labor and reduce the time taken for each production cycle. For instance, advanced mixing and baking systems allow for continuous production, ensuring a steady supply of freshly baked muffins.

Additionally, the use of **modular production lines** enables manufacturers to adjust their output based on demand fluctuations. This adaptability is crucial during peak seasons when consumer demand surges.

3.2 Enhanced Product Quality

Quality is paramount in the food industry, and an advanced muffin production line ensures that every batch meets stringent quality standards. Automated systems maintain uniform mixing and baking conditions, resulting in muffins with consistent texture and flavor.

Furthermore, state-of-the-art **quality control technologies**, such as in-line sensors and cameras, monitor the production process, identifying any deviations from the desired product specifications. This proactive approach to quality assurance minimizes waste and ensures customer satisfaction.

3.3 Scalability for Growing Businesses

As businesses expand, so do their production needs. An advanced muffin production line is inherently scalable, allowing manufacturers to increase their output without compromising quality. **Modular designs** facilitate easy upgrades and expansions, enabling businesses to add new equipment or production modules as demand grows.

This scalability is essential for businesses looking to enter new markets or respond to changing consumer preferences swiftly. With an advanced production line, manufacturers can adapt their operations to meet the evolving landscape of the food industry.

3.4 Cost-Effectiveness and Resource Management

Investing in advanced technology may seem daunting, but the long-term **cost-effectiveness** of an advanced muffin production line is undeniable. By automating processes, manufacturers can significantly reduce labor costs and minimize the risk of errors that lead to waste.

Moreover, advanced production lines are designed with **energy efficiency** in mind. Modern equipment consumes less energy and optimizes resource usage, resulting in lower operational expenses. This cost-saving aspect is particularly beneficial in an industry where profit margins can be tight.

3.5 Sustainability in Muffin Production

In recent years, sustainability has become a key focus in food production. An advanced muffin production line can incorporate eco-friendly practices, such as energy-efficient equipment and reduced waste generation.

By using sustainable ingredients and packaging solutions, manufacturers can appeal to environmentally-conscious consumers and enhance their brand image. Moreover, implementing **waste reduction techniques**—such as recycling and upcycling by-products—further contributes to a more sustainable production process.

4. Key Components of an Advanced Muffin Production Line

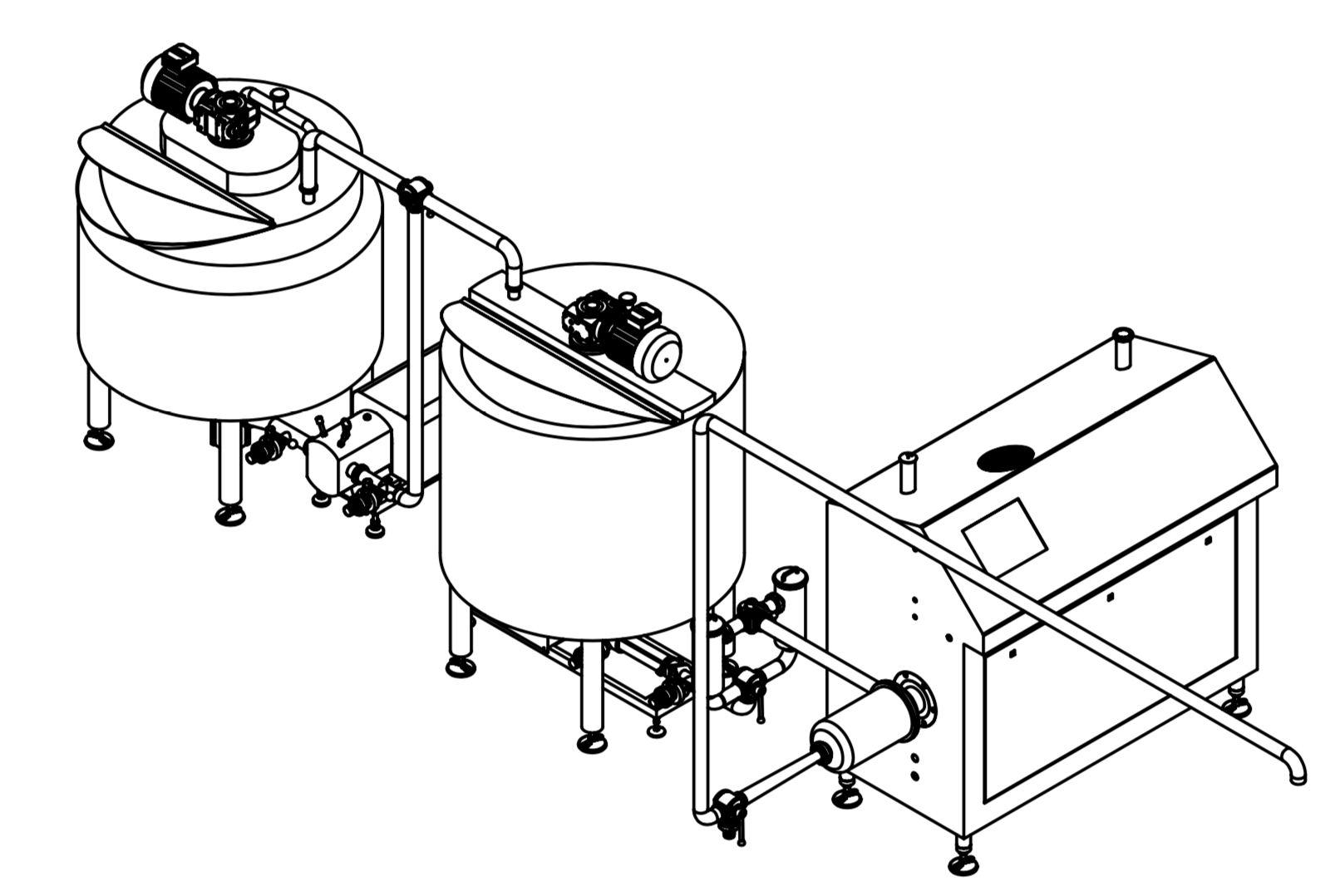

To maximize the benefits of an advanced muffin production line, it is essential to understand its key components. Each element works harmoniously to deliver high-quality muffins efficiently.

4.1 Automated Mixing Systems

Automated mixing systems are crucial for achieving consistent batter quality. These systems ensure precise ingredient measurements and optimal mixing times, resulting in uniform batter consistency across batches.

4.2 Precision Baking Equipment

Precision baking ovens equipped with advanced temperature controls provide even heat distribution, minimizing the risk of undercooked or overcooked muffins. Some ovens also feature humidity control, which is essential for achieving the desired texture.

4.3 Cooling and Packaging Solutions

After baking, muffins must be cooled rapidly to maintain freshness. Automated cooling tunnels ensure even cooling, while advanced packaging machines preserve the product's quality and extend shelf life.

4.4 Quality Control Systems

Incorporating real-time monitoring systems allows for immediate detection of any quality issues. These systems can track parameters such as weight, size, and surface quality, ensuring that only the best muffins reach consumers.

5. Current Trends in Muffin Production Technology

The muffin production industry is continuously evolving, with several trends shaping its future. Understanding these trends can help manufacturers stay ahead of the competition.

5.1 Plant-Based and Health-Conscious Options

As consumers increasingly seek healthier options, the demand for plant-based and low-sugar muffins is on the rise. Advanced production lines can easily accommodate the formulation of these alternative products, allowing manufacturers to diversify their offerings.

5.2 Smart Manufacturing

The integration of **IoT** (Internet of Things) technologies is revolutionizing food production. Manufacturers are leveraging smart devices to streamline operations, monitor equipment performance, and collect valuable data for continuous improvement.

5.3 Customization and Personalization

Consumers are looking for unique flavors and customized products. Advanced muffin production lines can adapt to small-batch production while maintaining high quality, enabling manufacturers to offer personalized muffin options.

6. Case Studies: Successful Muffin Production Implementations

Examining successful implementations of advanced muffin production lines can provide valuable insights for manufacturers considering such investments.

6.1 Case Study: ABC Bakery

ABC Bakery implemented an advanced production line that increased their output by 50% while maintaining product quality. By automating their mixing and baking processes, they reduced labor costs and minimized waste significantly.

6.2 Case Study: XYZ Foods

XYZ Foods focused on sustainability by integrating energy-efficient equipment into their muffin production line. This initiative not only reduced their carbon footprint but also resulted in substantial cost savings over time.

7. Frequently Asked Questions

7.1 What is an advanced muffin production line?

An advanced muffin production line is a fully automated system designed to streamline the manufacturing of muffins, ensuring high quality, consistency, and efficiency.

7.2 How does automation benefit muffin production?

Automation minimizes manual labor, reduces errors, and increases production speed, allowing manufacturers to meet growing consumer demands effectively.

7.3 Can an advanced production line accommodate different muffin flavors?

Yes, advanced muffin production lines can be designed to handle various flavors and formulations, providing flexibility for manufacturers.

7.4 What are the cost implications of implementing an advanced production line?

While the initial investment may be high, the long-term cost savings from reduced labor, minimized waste, and increased efficiency make advanced production lines cost-effective.

7.5 How can sustainability be achieved in muffin production?

Sustainability can be achieved by using energy-efficient equipment, sourcing organic ingredients, and implementing waste reduction practices.

8. Conclusion

The adoption of an **advanced muffin production line** is pivotal for manufacturers aiming to enhance efficiency, maintain product quality, and achieve scalability. As consumer preferences evolve towards healthier and more sustainable options, embracing innovative technologies will position companies to thrive in a competitive market. By understanding the benefits, components, and trends associated with advanced production lines, manufacturers can make informed decisions that lead to increased profitability and customer satisfaction. The future of muffin production is bright, and those who invest in advanced technologies are sure to reap the rewards.

advanced Muffin Production line

Previous Page