Crisis Management: Keeping Your Sponge Cake Production Line Running Smoothly

2025/06/20

Crisis Management: Keeping Your Sponge Cake Production Line Running Smoothly

Table of Contents

- Introduction to Crisis Management in Food Production

- Understanding Crisis Management

- Common Crises in Sponge Cake Production

- Prevention Strategies for a Smooth Production Line

- Implementing Real-Time Monitoring Systems

- Staff Training and Preparedness

- Developing an Effective Crisis Response Plan

- Case Studies: Successful Crisis Management

- Conclusion

- Frequently Asked Questions

Introduction to Crisis Management in Food Production

In the competitive landscape of the food and beverage industry, particularly in sponge cake production, the ability to effectively manage crises can make or break a business. Crises can arise from equipment failures, supply chain disruptions, or sudden changes in consumer demand. Understanding how to navigate these challenges is crucial to maintaining operational efficiency and product quality. In this article, we will explore the essential components of crisis management tailored to the unique needs of the sponge cake production line.

Understanding Crisis Management

Crisis management encompasses the strategies and actions taken by organizations to prepare for, respond to, and recover from unexpected events. Effective crisis management not only mitigates risks but also ensures business continuity. In the context of sponge cake production, it involves understanding potential risks, preparing staff, and establishing protocols to minimize downtime and maintain quality standards.

The Importance of Crisis Management in Sponge Cake Production

Sponge cake production involves various stages, from mixing ingredients to baking and packaging. Each stage presents unique challenges, and an unexpected crisis can halt production, leading to financial losses and damaged reputations. Implementing robust crisis management practices allows producers to respond swiftly, maintaining operations even during adverse events.

Common Crises in Sponge Cake Production

Identifying potential crises is the first step in developing effective management strategies. In sponge cake production, several common crises can disrupt operations:

1. Equipment Failures

Mechanical breakdowns can halt production, causing delays and necessitating costly repairs. Regular maintenance schedules and quick access to replacement parts can help mitigate these risks.

2. Supply Chain Disruptions

Delays in ingredient delivery or shortages can severely impact production timelines. Establishing strong relationships with suppliers and diversifying sources can provide a safety net during disruptions.

3. Quality Control Issues

Fluctuations in ingredient quality can lead to inconsistent product outcomes. Implementing strict quality control measures at each production stage can minimize these risks.

4. Regulatory Compliance Failures

Failure to adhere to food safety regulations can result in product recalls and legal repercussions. Staying informed about regulations and conducting regular audits ensure compliance.

Prevention Strategies for a Smooth Production Line

Proactive measures are essential to prevent crises from occurring. The following strategies can enhance the resilience of the sponge cake production line:

1. Regular Equipment Maintenance

Establish a routine maintenance schedule to ensure all machinery operates at peak performance. This includes regular inspections, cleaning, and timely repairs to prevent unexpected breakdowns.

2. Supplier Diversification

Avoid reliance on a single supplier by establishing relationships with multiple vendors. This provides alternatives in case of supply chain disruptions and ensures a steady flow of ingredients.

3. Quality Assurance Protocols

Implement a comprehensive quality assurance program that involves regular testing and evaluation of raw materials and finished products. This minimizes the risk of producing subpar products.

4. Staff Training

Invest in ongoing training for staff on crisis management protocols, equipment operation, and quality control measures. Well-informed employees are key to maintaining efficiency and addressing issues as they arise.

Implementing Real-Time Monitoring Systems

Technological advancements have made it easier to monitor production processes in real time. Implementing monitoring systems can help identify potential issues before they escalate.

1. Automation and Sensors

Utilizing automated systems and sensors throughout the production line can provide real-time data on equipment performance, ingredient quality, and environmental conditions. This allows for immediate corrective actions.

2. Data Analytics

Leveraging data analytics can provide insights into production patterns and highlight areas for improvement. Analyzing historical data can also help predict future challenges.

Staff Training and Preparedness

An informed workforce is critical when it comes to crisis management. Comprehensive training programs should cover:

1. Crisis Response Procedures

Staff should be well-versed in crisis response protocols, including emergency communication channels, evacuation procedures, and safety measures.

2. Role Assignments

Establish clear role assignments for staff during a crisis to ensure efficient responses. This includes designating individuals responsible for communication, equipment checks, and quality assessments.

3. Regular Drills

Conducting regular drills simulating potential crises can help staff practice their responses, ensuring they are prepared to act swiftly and effectively when real issues arise.

Developing an Effective Crisis Response Plan

A well-crafted crisis response plan outlines the steps your organization will take to address potential crises. Key elements include:

1. Risk Assessment

Conduct a thorough risk assessment to identify and prioritize potential crises based on their likelihood and impact.

2. Communication Strategy

Establish a clear communication strategy for internal and external stakeholders. This ensures everyone involved understands their roles and responsibilities during a crisis.

3. Recovery Procedures

Outline recovery procedures to restore normal operations as quickly as possible. This may involve contingency plans for sourcing materials, re-establishing supply chains, or temporary production measures.

Case Studies: Successful Crisis Management

Examining successful case studies can provide valuable insights into effective crisis management. Here are a few examples:

1. Equipment Breakdown Management

A sponge cake manufacturer experienced a critical equipment failure during peak production. By quickly implementing their crisis response plan, they were able to reroute production to alternate machines, minimizing downtime and meeting delivery deadlines.

2. Supply Chain Resilience

Another company faced ingredient shortages due to supplier issues. By maintaining relationships with multiple suppliers and tapping into their emergency contacts, they sourced replacement ingredients without affecting production quality.

3. Quality Control Success

A bakery faced a recall due to quality control failures. By establishing a more rigorous quality assurance program and investing in staff training, they improved their processes and regained consumer trust.

Conclusion

Crisis management in the sponge cake production line is not just about responding to issues; it is about proactively preparing for potential challenges. By implementing effective prevention strategies, embracing technological advancements, and fostering a culture of preparedness, businesses can navigate crises with confidence. A well-prepared production line not only ensures operational continuity but also enhances product quality and consumer satisfaction. The time to invest in crisis management is now, as it can safeguard your business against future disruptions and position you for long-term success.

Frequently Asked Questions

1. What are the most common crises in sponge cake production?

Common crises include equipment failures, supply chain disruptions, quality control issues, and regulatory compliance failures.

2. How can I prevent crises in my production line?

Implement regular maintenance schedules, diversify suppliers, establish quality assurance protocols, and invest in staff training to minimize risks.

3. What role does technology play in crisis management?

Technology, such as real-time monitoring systems and data analytics, enables manufacturers to detect issues early, facilitating swift responses.

4. Why is staff training important in crisis management?

Well-trained staff are crucial for executing crisis response protocols effectively, ensuring that all team members know their roles during a crisis.

5. How can I develop a crisis response plan?

Conduct a risk assessment, establish a communication strategy, and outline recovery procedures in your crisis response plan to ensure effective management of potential crises.

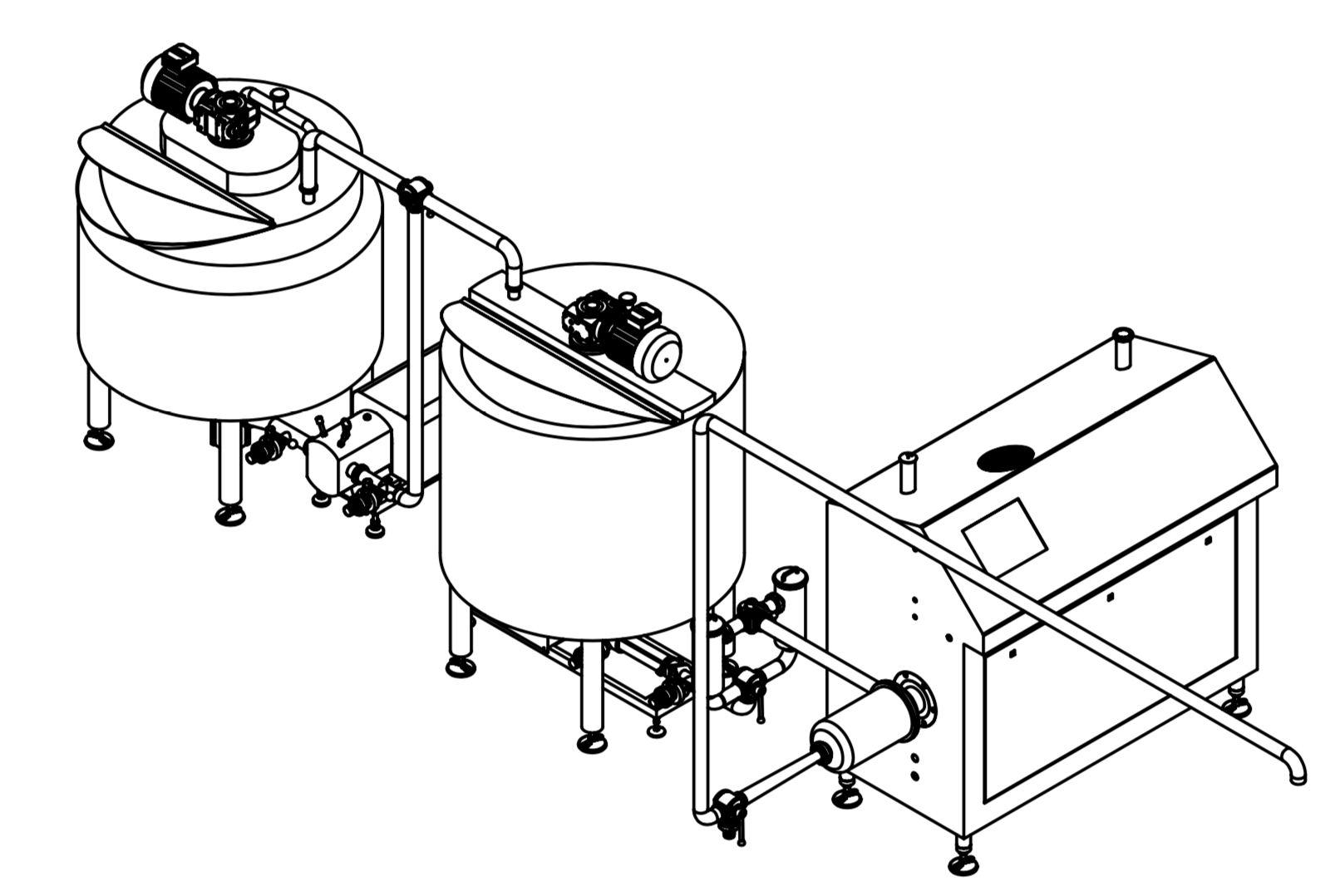

Sponge cake Production line