Enhance Your Production Line with a Cream Aeration Machine: Unlocking Efficiency and Quality in Food Processing

2025/12/01

Enhance Your Production Line with a Cream Aeration Machine

In the competitive world of food processing, the quest for efficiency and quality drives manufacturers to seek innovative solutions. One such solution that stands out is the cream aeration machine. This specialized equipment not only enhances the texture and flavor of cream-based products but also boosts the overall productivity of your production line. In this article, we will explore the myriad benefits of integrating a cream aeration machine into your food processing operations, focusing on its role in the food and beverage industry and specifically in the production of snacks.

Understanding Cream Aeration Machines

What is a Cream Aeration Machine?

A cream aeration machine is a specialized piece of equipment designed to incorporate air into cream and other similar products, resulting in a lighter, fluffier texture. This process enhances the mouthfeel and overall sensory experience of the final product, making it more appealing to consumers. Aeration is crucial in various applications, including whipped creams, mousses, and certain dessert products. By using a cream aeration machine, manufacturers can achieve consistent results and maintain high-quality standards across batches.

How Does a Cream Aeration Machine Work?

The cream aeration process typically involves several steps. First, the machine draws in cream and mixes it with air through a series of high-speed blades or paddles. As the cream is agitated, air bubbles are introduced, leading to the aeration process. The specific settings on the machine can be adjusted to control the amount of air incorporated, allowing for customization based on the desired product characteristics. The result is a stable emulsion that retains its texture and volume over time, even under varying temperature conditions.

The Advantages of Using Cream Aeration Machines in Food Processing

1. Improved Product Quality

One of the most significant benefits of using a cream aeration machine is the enhancement of product quality. Aerated cream products typically exhibit superior texture, volume, and stability. This is particularly important for items such as whipped cream and desserts, where a light, airy texture is desired. Consumers often associate these qualities with freshness and premium quality, making them more likely to choose such products over non-aerated alternatives.

2. Increased Efficiency in Production

Manufacturers are always looking for ways to optimize production lines and reduce costs. Cream aeration machines can significantly increase efficiency by automating the aeration process. Traditional methods of aerating cream often involve manual labor and time-consuming techniques that can lead to inconsistency. In contrast, a cream aeration machine allows for rapid processing, enabling manufacturers to meet high demand while maintaining quality standards.

3. Consistency and Reproducibility

Consistency in product quality is vital for brand reputation and customer satisfaction. Cream aeration machines are designed to ensure that each batch of cream is aerated uniformly, resulting in products that have the same texture and flavor profile every time. This reproducibility is crucial for manufacturers looking to maintain a loyal customer base, as consumers expect the same high quality in every purchase.

4. Versatility in Applications

Cream aeration machines are not limited to a single type of product or application. Their versatility allows them to be used in various food processing scenarios, including the production of whipped toppings, mousses, and even certain snack foods. This adaptability makes them a valuable asset in any food production facility, as they can cater to a wide range of consumer preferences and market trends.

5. Enhanced Shelf Life

Another essential benefit of using a cream aeration machine is the potential to extend the shelf life of aerated products. Proper aeration helps stabilize emulsions, reducing the risk of separation and spoilage. This is particularly important for manufacturers looking to distribute their products over long distances or store them for extended periods. An extended shelf life not only benefits manufacturers by reducing waste but also ensures consumers receive fresher products.

Choosing the Right Cream Aeration Machine for Your Production Line

Factors to Consider When Selecting a Cream Aeration Machine

Investing in a cream aeration machine is a decision that requires careful consideration. Here are some key factors to keep in mind:

1. Production Capacity

Evaluate your production requirements to determine the appropriate capacity for your cream aeration machine. Consider the volume of cream you plan to process daily, as well as any future growth projections. Selecting a machine with the right capacity will optimize your production efficiency and reduce the risk of bottlenecks.

2. Aeration Method

Cream aeration machines utilize different methods to incorporate air into the cream. Some machines use high-speed mixing, while others may rely on vacuum aeration techniques. Understand the advantages and limitations of each method to choose the one that aligns with your production goals and product specifications.

3. Ease of Cleaning and Maintenance

Hygiene is paramount in the food processing industry. Choose a cream aeration machine that is easy to clean and maintain, as this will help you adhere to strict food safety regulations and prevent cross-contamination. Look for machines with removable parts and smooth surfaces that facilitate thorough cleaning.

4. Energy Efficiency

Energy costs can significantly impact the overall cost of production. Opt for a cream aeration machine that prioritizes energy efficiency without compromising performance. This not only reduces operational costs but also aligns with sustainable practices that are increasingly important in the food industry.

5. Technical Support and Warranty

When investing in specialized machinery, it's essential to ensure that the manufacturer offers reliable technical support and a comprehensive warranty. This will give you peace of mind, knowing that any potential issues can be addressed promptly to minimize downtime in your production line.

Best Practices for Operating a Cream Aeration Machine

1. Calibrate Your Machine Regularly

Regular calibration of your cream aeration machine is crucial to maintaining optimal performance. This process helps ensure that the aeration process remains consistent and meets your quality standards. Follow the manufacturer's guidelines for calibration schedules and procedures to achieve the best results.

2. Monitor Cream Temperature

The temperature of the cream being processed can significantly affect the aeration process. Warmer cream may not aerate effectively, while colder cream may achieve better results. Maintain optimal cream temperatures as recommended by the machine manufacturer for the best aeration outcomes.

3. Train Your Staff

Proper training for your staff is essential to maximize the efficiency of your cream aeration machine. Ensure that operators understand the machine's functions, maintenance requirements, and safety protocols. This will help prevent accidents, reduce errors, and promote a smooth production process.

4. Conduct Regular Maintenance

Scheduled maintenance of your cream aeration machine is vital for prolonging its lifespan and ensuring consistent performance. Follow the manufacturer's maintenance recommendations and keep a log of all servicing performed. Regular inspections can help identify potential issues before they escalate, saving you time and money in the long run.

5. Gather Feedback on Product Quality

Collect feedback from consumers and quality control teams regarding the texture and flavor of your aerated cream products. This information can help you make necessary adjustments to the aeration process and improve overall product quality. Continuous improvement is key to staying competitive in the food processing industry.

Frequently Asked Questions (FAQs)

1. What types of products can be made using a cream aeration machine?

A cream aeration machine can be used to produce a variety of products, including whipped cream, mousses, airy desserts, and certain snack items. Its versatility allows manufacturers to cater to diverse consumer preferences.

2. How does aeration affect the texture and taste of cream products?

Aeration incorporates air into the cream, resulting in a lighter texture and enhanced mouthfeel. This process also allows flavors to be more pronounced, leading to a more enjoyable consumer experience.

3. Are cream aeration machines difficult to operate?

Most cream aeration machines are designed for ease of use. However, proper training is essential to ensure that operators can utilize the equipment effectively and safely.

4. How often should I clean my cream aeration machine?

Cleaning frequency will depend on your production volume and the specific recommendations of the machine manufacturer. Regular cleaning after each production batch is typically advised to maintain hygiene and prevent contamination.

5. Can I customize the aeration settings for different products?

Yes, many cream aeration machines allow for customization of aeration settings. This feature enables manufacturers to adjust the amount of air incorporated based on the specific requirements of different products, ensuring optimal texture and stability.

Conclusion

Integrating a cream aeration machine into your production line is a strategic move that can significantly enhance product quality, improve efficiency, and meet consumer demands for diverse food products. By understanding the benefits, selecting the right machine, and following best operational practices, manufacturers can effectively leverage this technology to stay competitive in the rapidly evolving food processing industry. As the demand for high-quality aerated products continues to rise, investing in a cream aeration machine is not just a choice; it's a necessity for future success.

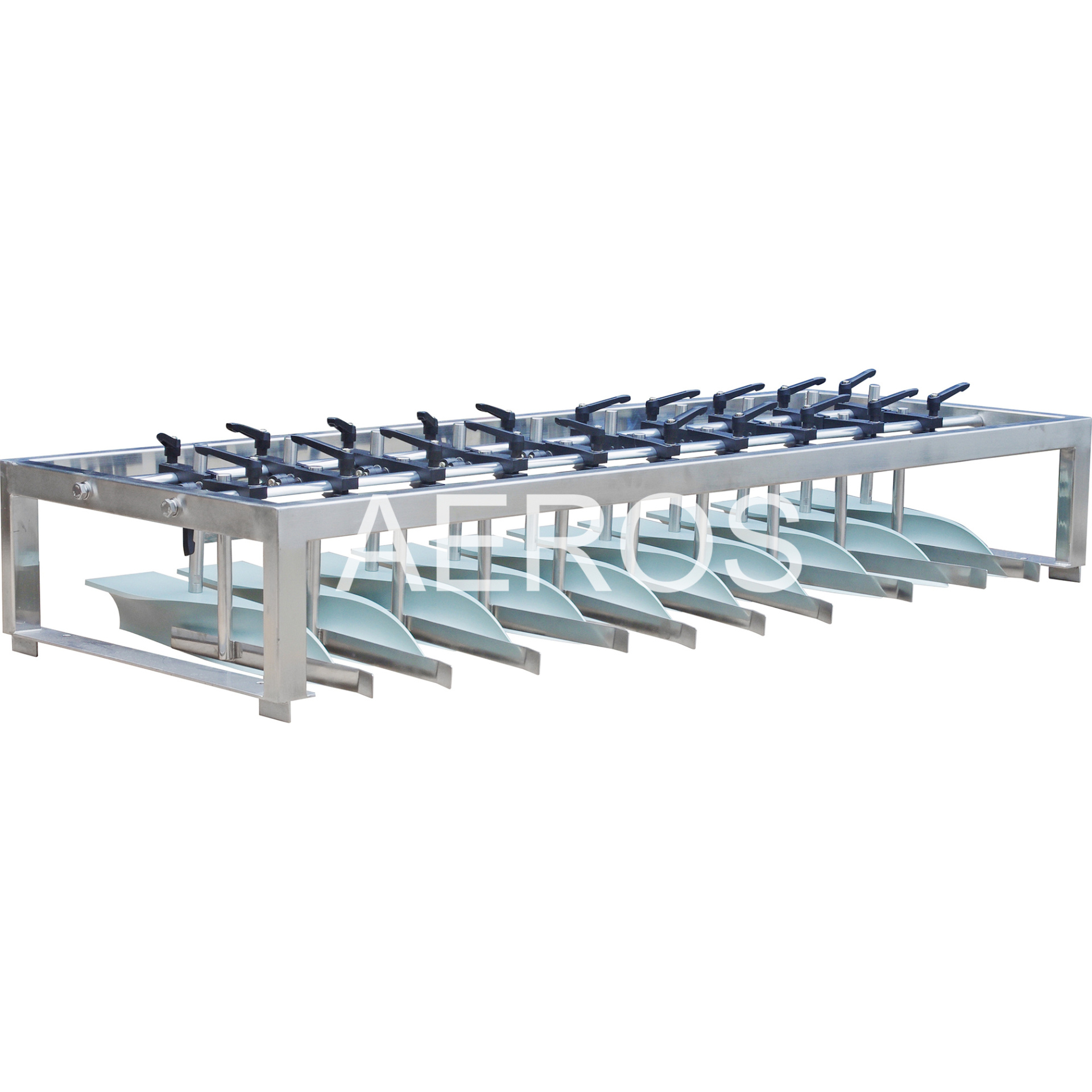

Cream aeration machine