Maximizing Efficiency in Cream Production Lines: A Comprehensive Guide

2025/12/01

The cream production line is a critical component in the food processing industry, particularly for manufacturers of dairy products and desserts. Understanding the various elements involved can lead to enhanced efficiency, improved quality, and significant cost savings. This guide will delve into essential aspects of cream production lines, highlighting the technology and processes that drive success in this field.

At the heart of any cream production line is the pasteurization process. This step is crucial for ensuring food safety by eliminating harmful bacteria while preserving the quality of the cream. Modern pasteurization techniques, such as High-Temperature Short Time (HTST) and Ultra-High Temperature (UHT) processing, allow for rapid heating and cooling, maintaining the cream's flavor and nutritional value. Investing in advanced pasteurization equipment not only ensures compliance with health regulations but also enhances the overall efficiency of the production line.

Following pasteurization, homogenization is the next pivotal step in the cream production process. This stage breaks down fat molecules to create a stable emulsion, resulting in a smoother texture and improved mouthfeel. Employing high-pressure homogenizers can significantly enhance the consistency of the final product, reducing the need for additional stabilizers and ensuring uniformity throughout production.

An essential aspect of optimizing a cream production line lies in automation and control systems. Implementing a fully automated system can drastically reduce labor costs and human error. Advanced sensors and monitoring systems enable real-time data collection, which is essential for maintaining optimal production conditions. The integration of IoT (Internet of Things) technology can offer insights into machine performance and product quality, allowing for timely adjustments and preventative maintenance.

Furthermore, the layout of the cream production line is vital for maximizing workflow efficiency. A well-designed layout minimizes bottlenecks and ensures smooth transitions between different stages of production. Incorporating modular designs can facilitate easy modifications and upgrades, accommodating future growth and technological advancements.

Quality control remains a cornerstone of successful cream production. Regular testing and monitoring of both raw materials and finished products are necessary to ensure compliance with industry standards. Implementing stringent quality assurance protocols can help identify any deviations early in the production process, thus safeguarding the final product's integrity.

In conclusion, a well-optimized cream production line incorporates advanced pasteurization, effective homogenization, automation technology, and strategic layout design to maximize efficiency and product quality. By focusing on these key areas, manufacturers can ensure they remain competitive in the ever-evolving food and beverage industry. Embracing innovation and maintaining rigorous quality control standards will not only enhance production efficiency but also foster consumer trust in the products delivered to the market.

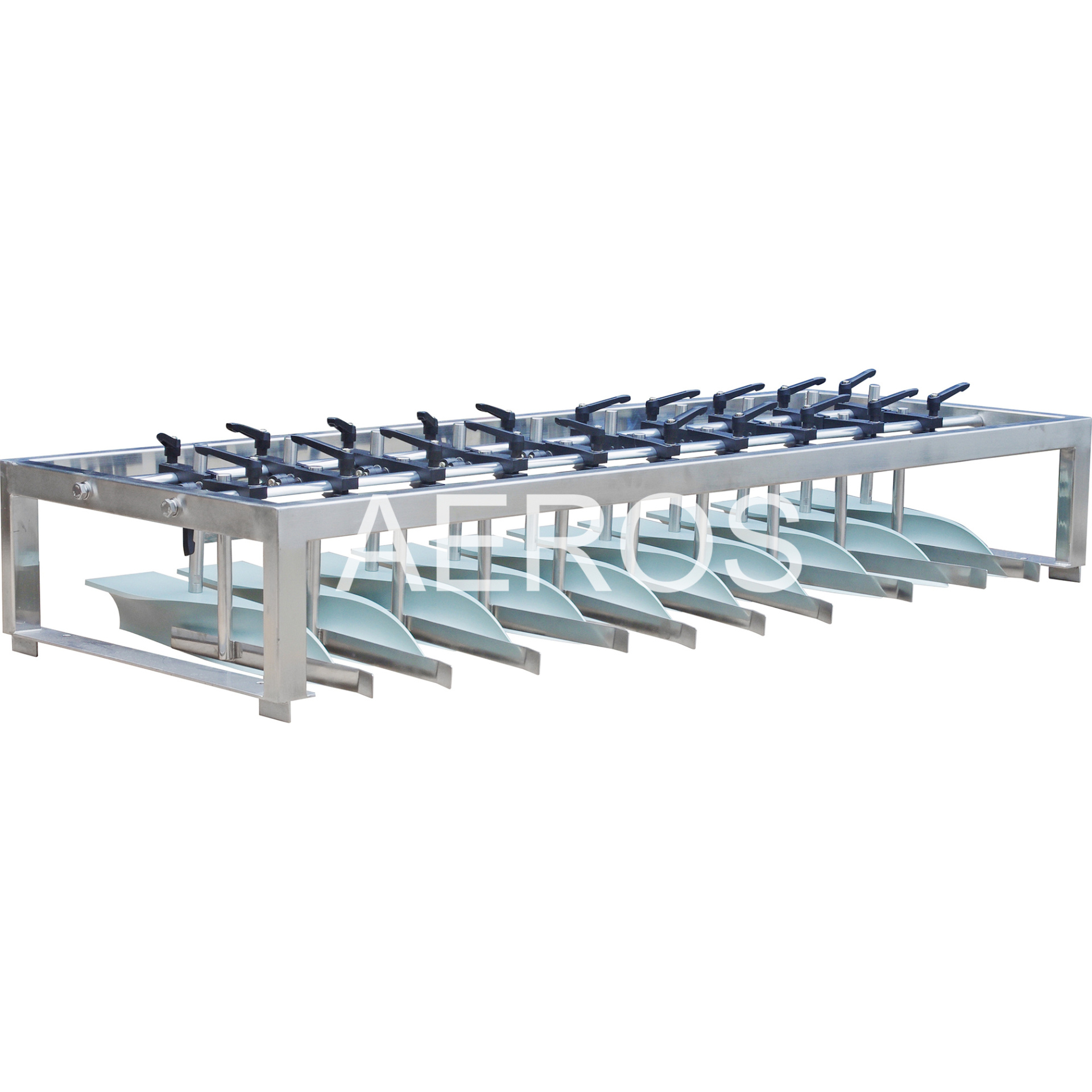

Cream production line