Transform Your Chocolate Production with an Aerator: A Comprehensive Guide

2025/12/25

Transform Your Chocolate Production with an Aerator: A Comprehensive Guide

Table of Contents

- Introduction to Chocolate Aeration

- Understanding Aeration in Chocolate Production

- Benefits of Using Aerators in Chocolate Manufacturing

- Types of Aerators for Chocolate Processing

- Choosing the Right Aerator for Your Production Needs

- Implementing Aerators in Your Chocolate Production Line

- Best Practices for Aerating Chocolate

- Common Mistakes to Avoid When Using Aerators

- Case Studies: Success Stories in Chocolate Aeration

- Frequently Asked Questions

- Conclusion

Introduction to Chocolate Aeration

The art of chocolate making has evolved significantly over the years. Among the myriad of innovations, **aeration** stands out as a critical process that dramatically enhances the quality and appeal of chocolate products. In an era where consumers are increasingly discerning about texture and mouthfeel, incorporating aerators in chocolate production can transform your offerings from ordinary to extraordinary.

Understanding Aeration in Chocolate Production

Aeration refers to the process of incorporating air into a product, which can significantly alter its physical properties. In chocolate production, aeration is not merely about volume; it’s about creating a **light and creamy texture** that enhances the overall eating experience. By introducing air bubbles into the chocolate mixture, manufacturers can achieve a smoother consistency, improve melt-in-the-mouth sensations, and create intriguing flavor profiles.

The Science Behind Aeration

When air is introduced during the mixing process, it affects the **viscosity** and **density** of the chocolate. This interaction leads to a reduction in the chocolate's weight while enhancing its volume, making it appear more luxurious without compromising on quality.

Benefits of Using Aerators in Chocolate Manufacturing

Integrating aerators into your chocolate production line offers numerous benefits that can help set your products apart in a competitive market.

Improved Texture and Mouthfeel

One of the primary advantages of aeration is the improvement in texture. Chocolate with optimal aeration is not only smoother but also has a more luxurious mouthfeel, which can enhance customer satisfaction.

Increased Volume and Yield

Aerating chocolate can increase the volume of the final product. This means manufacturers can produce more chocolate with the same amount of raw materials, leading to higher yields and reduced costs.

Enhanced Flavor Profiles

Aeration can also enhance the flavor experience by increasing the surface area of the chocolate. This allows for better interaction with the taste buds, leading to a more pronounced flavor profile.

Better Consistency and Stability

Consistent aeration contributes to the overall stability of chocolate, reducing the likelihood of separation or other quality issues during storage and distribution.

Types of Aerators for Chocolate Processing

There are various aerators available for chocolate production, each designed to meet specific processing needs.

Blade Aerators

Blade aerators are commonly used due to their ability to efficiently introduce air into the chocolate mixture. They work by creating a vortex that pulls air into the product, resulting in uniform aeration.

Rotary Aerators

Rotary aerators utilize a rotating mechanism to blend air into the chocolate. These are particularly effective for large-scale production where consistency is crucial.

Pneumatic Aerators

Pneumatic aerators use compressed air to infuse air into the chocolate. They are highly efficient and often employed in continuous production processes.

Choosing the Right Aerator for Your Production Needs

Selecting the appropriate aerator is critical to maximizing the benefits of aeration in chocolate production. Consider the following factors:

Production Scale

For small to medium-sized operations, a blade or rotary aerator may suffice. However, for larger manufacturing plants, pneumatic aerators can deliver the necessary efficiency and consistency.

Chocolate Type

Different chocolate types may require specialized aeration techniques. For example, milk chocolate may need different settings compared to dark chocolate due to variations in fat content.

Desired Texture

Understanding the end product's texture requirements will help guide your choice of aerator. If a light and airy texture is desired, ensure that the aerator can produce this consistently.

Implementing Aerators in Your Chocolate Production Line

Once the right aerator is chosen, proper implementation is essential for maximizing its effectiveness.

Training Staff

Ensure that your staff is trained on how to operate the aerator properly. Understanding the mechanics of aeration will help prevent mishaps that can lead to poor quality chocolate.

Testing and Calibration

Regular testing and calibration of the aerator are crucial. Consistency in aeration levels will ensure that every batch of chocolate meets quality standards.

Monitoring Temperature and Humidity

Temperature and humidity can significantly affect the aeration process. Monitor these factors closely to maintain optimal conditions for chocolate production.

Best Practices for Aerating Chocolate

To achieve the best results from aerators, consider the following best practices:

Use High-Quality Ingredients

The quality of raw materials directly influences the final product. Invest in high-quality cocoa and other ingredients to ensure that the aeration process yields superior chocolate.

Optimize Mixing Times

Balancing the mixing time is essential. Over-aeration can lead to undesirable textures, while under-aeration may not provide the necessary lightness.

Regular Maintenance of Equipment

Routine maintenance of the aerator and other processing equipment will ensure longevity and optimal performance.

Common Mistakes to Avoid When Using Aerators

While aeration can elevate chocolate production, several pitfalls should be avoided:

Inconsistent Aeration Levels

Inconsistent aeration can lead to variations in texture and taste. Regular monitoring and calibration can help mitigate this issue.

Ignoring Quality Control

Failing to implement strict quality control measures can result in poor-quality chocolate. Establishing a robust QC process is crucial.

Neglecting Staff Training

Underestimating the importance of staff training can lead to operational inefficiencies. Ensure that all team members understand the aeration process thoroughly.

Case Studies: Success Stories in Chocolate Aeration

Several companies have successfully integrated aerators into their chocolate production lines, leading to remarkable results.

Case Study 1: Large-scale Manufacturer

A large chocolate manufacturer implemented pneumatic aerators, resulting in a **20% increase in production efficiency** and an enhanced product line that appealed to a broader audience.

Case Study 2: Artisan Chocolate Maker

An artisan chocolate producer used blade aerators to create a unique texture for their premium chocolate bars, setting them apart in a competitive market.

Frequently Asked Questions

1. What types of chocolate can benefit from aeration?

Aeration is beneficial for various chocolate types, including dark, milk, and white chocolate, as it improves texture and flavor.

2. How does aeration affect chocolate shelf life?

Aeration can enhance shelf life by creating a more stable product, but proper storage conditions are also essential.

3. Can I aerate chocolate at home?

While industrial aerators are best for large batches, home chocolatiers can experiment with manual aeration techniques using whisking methods.

4. How do I know if my chocolate is adequately aerated?

Taste testing and texture evaluation are key indicators. Properly aerated chocolate should feel smooth and light on the palate.

5. What maintenance does an aerator require?

Regular cleaning, calibration, and inspection of the aerator will ensure optimal performance and longevity.

Conclusion

Incorporating an aerator into your chocolate production process can dramatically enhance the quality of your products while optimizing efficiency. By understanding the principles of aeration, selecting the right equipment, and following best practices, you can transform your chocolate offerings into delectable delights that captivate consumers. As the chocolate industry continues to evolve, the integration of innovative techniques like aeration will undoubtedly set the standard for excellence. Embrace this transformative approach and watch your chocolate production soar to new heights!

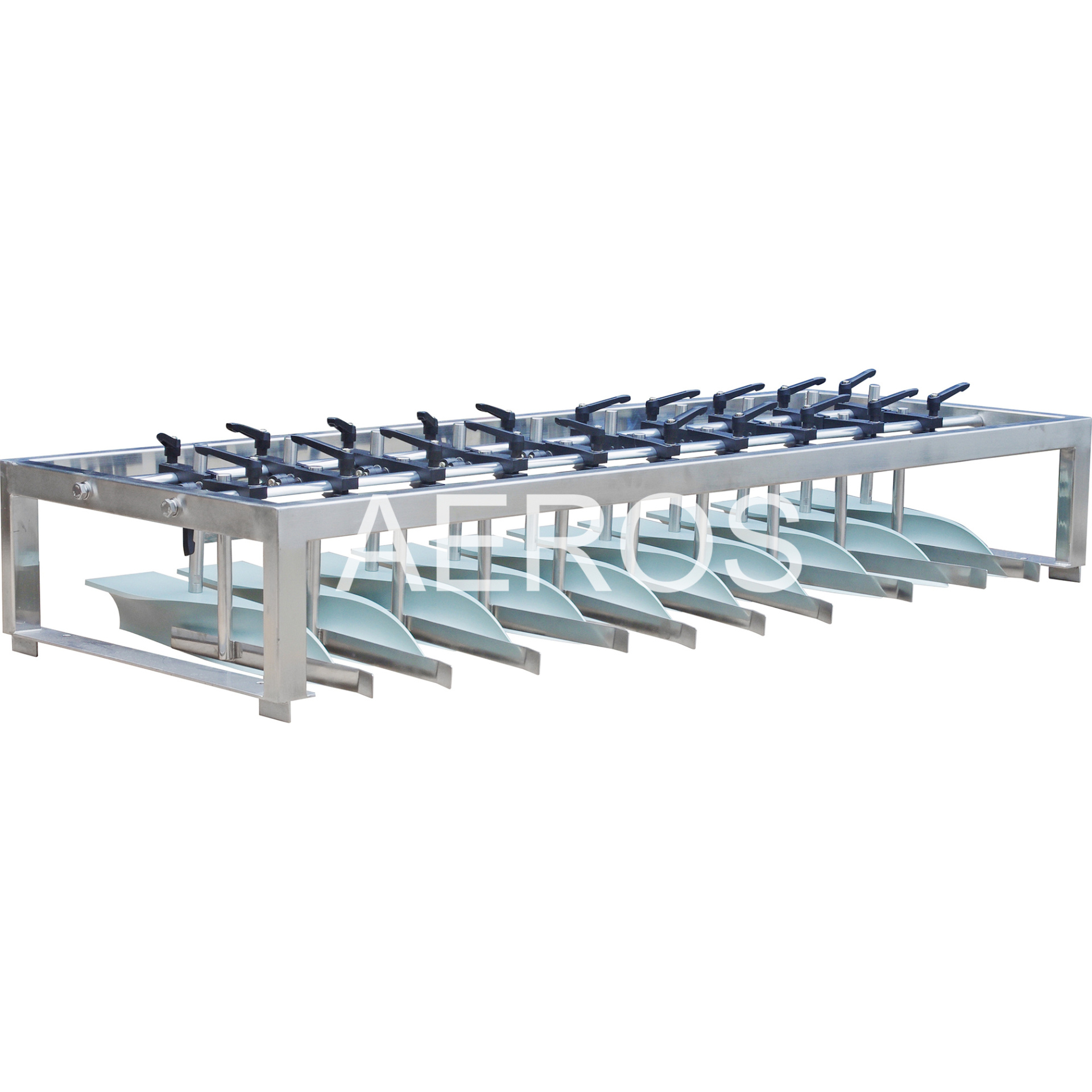

Chocolate aerator

Previous Page