Revolutionizing Indulgence: The Aerated Chocolate Production Line

2025/12/22

The production of aerated chocolate has gained significant popularity in the confectionery industry, as it offers a unique texture and mouthfeel that differentiates it from traditional chocolate products. An aerated chocolate production line employs sophisticated technology to infuse air into the chocolate mixture, resulting in a light, fluffy texture that enhances the eating experience. This process not only alters the physical properties of chocolate but also improves its flavor profile, making it a favored choice for many consumers.

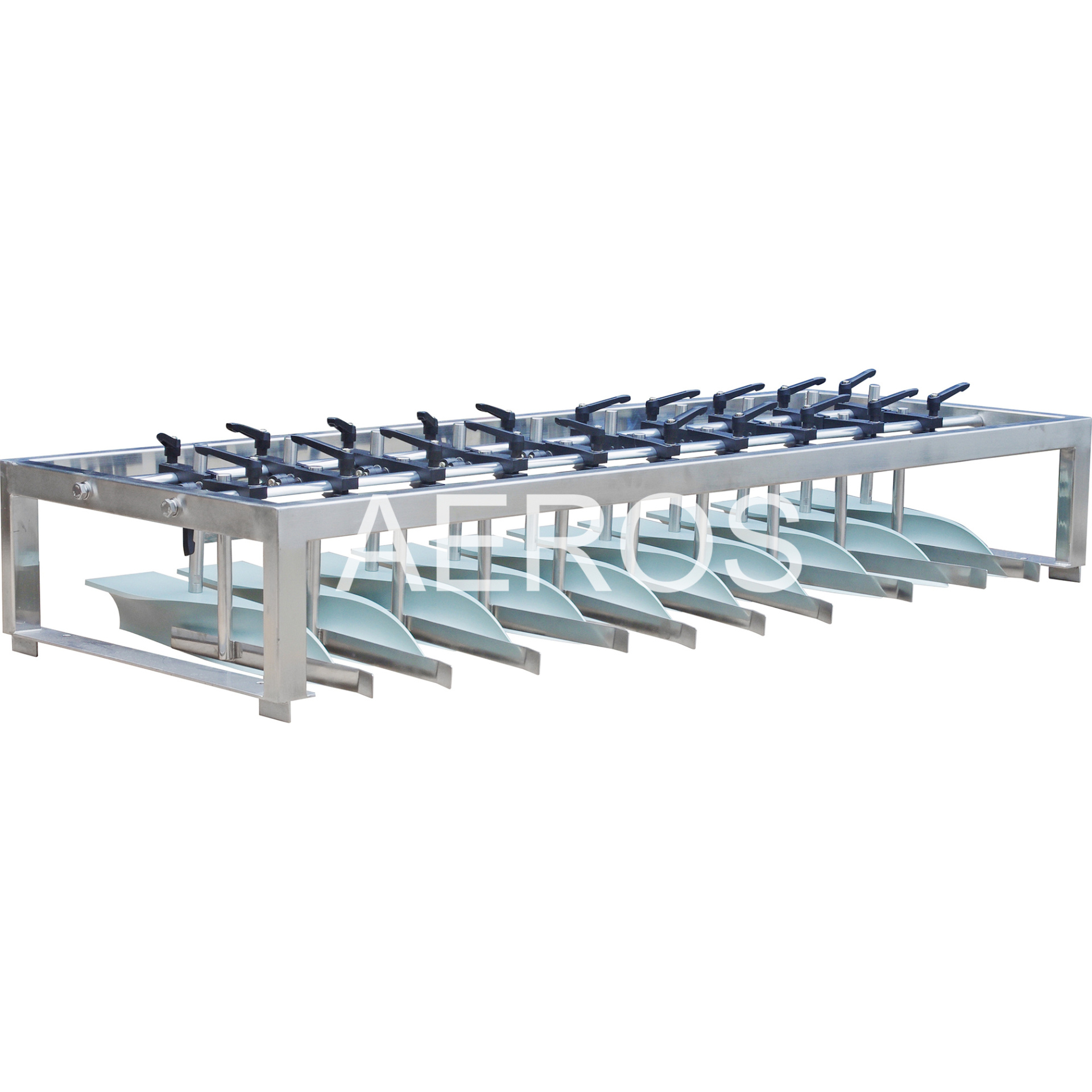

At the heart of an aerated chocolate production line is the aeration process, where cocoa mass, sugar, and other ingredients are combined and whipped to incorporate air. This is typically achieved using specialized mixing and whipping equipment designed to create a uniform emulsion. The aerated mixture is then tempered to stabilize the chocolate, ensuring that it retains its structure and sheen once cooled and molded. The entire process is carefully monitored to achieve the desired level of aeration, which can range from light to highly aerated, depending on the product specifications.

One of the key benefits of using an aerated chocolate production line is the reduction in the overall weight of the final product without compromising on taste. This can lead to cost savings in raw material usage and appeal to health-conscious consumers looking for lighter indulgences. Moreover, aerated chocolates can create unique product offerings, such as bars with unexpected textures or fillings, appealing to a wider audience.

The engineering behind an aerated chocolate production line also emphasizes efficiency and consistency. Modern machinery is designed to operate seamlessly, minimizing downtime and ensuring that production runs smoothly. Features like automated controls and monitoring systems allow for precise adjustments during the aeration and tempering phases, which is crucial for maintaining product quality.

In addition to the manufacturing process, the packaging of aerated chocolates also plays a vital role in preserving their unique characteristics. Proper packaging prevents moisture ingress and preserves the aerated structure, ensuring that consumers enjoy the intended texture and taste. Manufacturers often explore innovative packaging solutions that highlight the product's distinct features while ensuring optimal shelf life.

Overall, an aerated chocolate production line is a testament to the advancements in food processing technology, combining creativity with engineering excellence. Whether you are a manufacturer looking to expand your product line or a consumer eager to explore new confectionery experiences, the world of aerated chocolate offers an exciting journey into the future of sweets. As the demand for unique and indulgent treats grows, investing in sophisticated production lines will be key to staying competitive in the dynamic food industry.

At the heart of an aerated chocolate production line is the aeration process, where cocoa mass, sugar, and other ingredients are combined and whipped to incorporate air. This is typically achieved using specialized mixing and whipping equipment designed to create a uniform emulsion. The aerated mixture is then tempered to stabilize the chocolate, ensuring that it retains its structure and sheen once cooled and molded. The entire process is carefully monitored to achieve the desired level of aeration, which can range from light to highly aerated, depending on the product specifications.

One of the key benefits of using an aerated chocolate production line is the reduction in the overall weight of the final product without compromising on taste. This can lead to cost savings in raw material usage and appeal to health-conscious consumers looking for lighter indulgences. Moreover, aerated chocolates can create unique product offerings, such as bars with unexpected textures or fillings, appealing to a wider audience.

The engineering behind an aerated chocolate production line also emphasizes efficiency and consistency. Modern machinery is designed to operate seamlessly, minimizing downtime and ensuring that production runs smoothly. Features like automated controls and monitoring systems allow for precise adjustments during the aeration and tempering phases, which is crucial for maintaining product quality.

In addition to the manufacturing process, the packaging of aerated chocolates also plays a vital role in preserving their unique characteristics. Proper packaging prevents moisture ingress and preserves the aerated structure, ensuring that consumers enjoy the intended texture and taste. Manufacturers often explore innovative packaging solutions that highlight the product's distinct features while ensuring optimal shelf life.

Overall, an aerated chocolate production line is a testament to the advancements in food processing technology, combining creativity with engineering excellence. Whether you are a manufacturer looking to expand your product line or a consumer eager to explore new confectionery experiences, the world of aerated chocolate offers an exciting journey into the future of sweets. As the demand for unique and indulgent treats grows, investing in sophisticated production lines will be key to staying competitive in the dynamic food industry.

Aerated chocolate production line