Unlocking the Secrets of Marshmallow Extruders: Essential Insights for Food Processing Machinery

2025/12/03

Marshmallow extruders are specialized machines designed to create marshmallow products by pumping and shaping a mixture of sugar, water, and gelatin into desired forms. These machines play a pivotal role in the candy manufacturing industry, where consistency, texture, and quality are of utmost importance. Understanding the functionalities and benefits of marshmallow extruders can significantly enhance production efficiency and product quality.

One primary element of a marshmallow extruder is its ability to mix and aerate the ingredients thoroughly. The initial mixing process is crucial, as it affects the final texture and taste of the marshmallow. A well-designed extruder ensures that air is incorporated into the mixture, creating a light and fluffy marshmallow. This aeration is achieved through the use of specialized mixing blades and adjustable speed settings that allow for precise control over the mixture's consistency.

Furthermore, marshmallow extruders are equipped with temperature control features, which are essential for maintaining the right viscosity of the mixture during extrusion. The temperature must be closely monitored, as it directly influences the setting time and the overall quality of the marshmallow. An efficient marshmallow extruder will incorporate heating elements that can maintain optimal temperatures throughout the production process, ensuring that the marshmallow sets correctly and retains its shape.

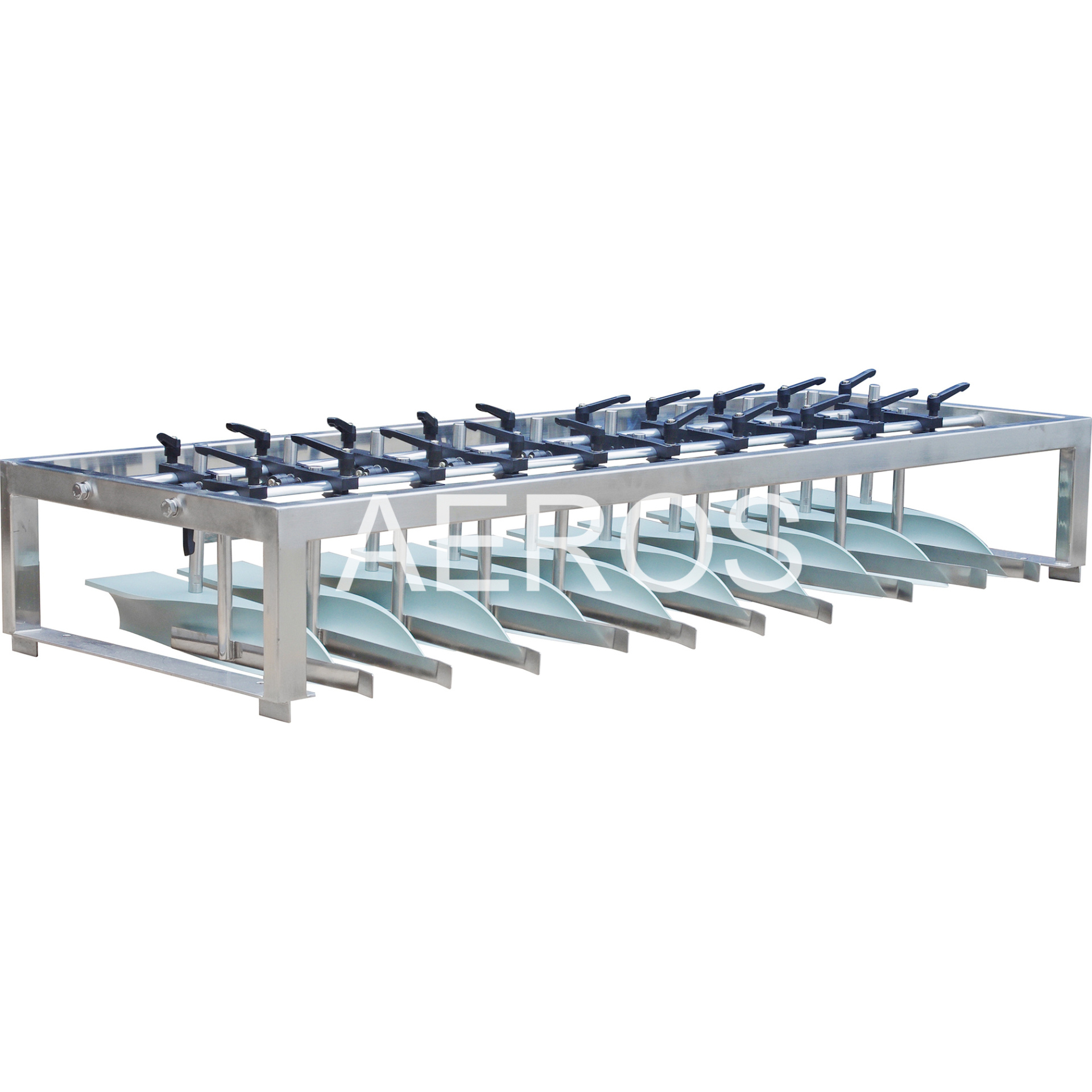

Another important aspect of marshmallow extruders is their ability to create various shapes and sizes of marshmallow products. This versatility is achieved through interchangeable die heads that can be easily swapped out to produce different designs. Manufacturers can customize their output to meet consumer demands for novelty shapes, seasonal products, or specific sizes, allowing for greater creativity and market competitiveness.

Additionally, automation features in modern marshmallow extruders enhance production efficiency. Automated systems can monitor and adjust parameters in real-time, ensuring consistent quality while minimizing manual labor. These advancements not only streamline the production process but also reduce the likelihood of human error, further improving product reliability.

Finally, maintenance and cleaning of marshmallow extruders are key considerations for manufacturers. Regular maintenance ensures that the machines operate smoothly and efficiently, while proper cleaning protocols prevent cross-contamination and uphold product safety standards. It's essential for manufacturers to follow the manufacturer's guidelines for maintenance schedules and cleaning procedures to prolong the lifespan of the equipment.

In summary, marshmallow extruders are a vital component in the candy manufacturing industry, offering precision, efficiency, and versatility. By understanding and utilizing these machines effectively, manufacturers can enhance product quality, streamline production processes, and stay competitive in a dynamic market.

One primary element of a marshmallow extruder is its ability to mix and aerate the ingredients thoroughly. The initial mixing process is crucial, as it affects the final texture and taste of the marshmallow. A well-designed extruder ensures that air is incorporated into the mixture, creating a light and fluffy marshmallow. This aeration is achieved through the use of specialized mixing blades and adjustable speed settings that allow for precise control over the mixture's consistency.

Furthermore, marshmallow extruders are equipped with temperature control features, which are essential for maintaining the right viscosity of the mixture during extrusion. The temperature must be closely monitored, as it directly influences the setting time and the overall quality of the marshmallow. An efficient marshmallow extruder will incorporate heating elements that can maintain optimal temperatures throughout the production process, ensuring that the marshmallow sets correctly and retains its shape.

Another important aspect of marshmallow extruders is their ability to create various shapes and sizes of marshmallow products. This versatility is achieved through interchangeable die heads that can be easily swapped out to produce different designs. Manufacturers can customize their output to meet consumer demands for novelty shapes, seasonal products, or specific sizes, allowing for greater creativity and market competitiveness.

Additionally, automation features in modern marshmallow extruders enhance production efficiency. Automated systems can monitor and adjust parameters in real-time, ensuring consistent quality while minimizing manual labor. These advancements not only streamline the production process but also reduce the likelihood of human error, further improving product reliability.

Finally, maintenance and cleaning of marshmallow extruders are key considerations for manufacturers. Regular maintenance ensures that the machines operate smoothly and efficiently, while proper cleaning protocols prevent cross-contamination and uphold product safety standards. It's essential for manufacturers to follow the manufacturer's guidelines for maintenance schedules and cleaning procedures to prolong the lifespan of the equipment.

In summary, marshmallow extruders are a vital component in the candy manufacturing industry, offering precision, efficiency, and versatility. By understanding and utilizing these machines effectively, manufacturers can enhance product quality, streamline production processes, and stay competitive in a dynamic market.

Marshmallow extruder