Transforming Your Bakery: The Advantages of a Fancy Cake Production System

2025/07/22

Transforming Your Bakery: The Advantages of a Fancy Cake Production System

In today’s competitive food industry, bakeries are constantly seeking innovative ways to enhance their production processes. The introduction of a fancy cake production system can be a game-changer for bakeries of all sizes. This article will delve into the numerous advantages of adopting such systems, ranging from improved efficiency and quality to enhanced creativity and profitability.

Table of Contents

- Introduction to Fancy Cake Production Systems

- Key Benefits of a Fancy Cake Production System

- Enhancing Efficiency in Cake Production

- Achieving Consistency in Quality and Taste

- Fostering Creativity with Advanced Technology

- Boosting Profitability through Increased Production

- Steps to Implement a Cake Production System

- Overcoming Challenges in Transitioning to a Fancy Cake Production System

- Conclusion: The Future of Bakery Operations

- Frequently Asked Questions

Introduction to Fancy Cake Production Systems

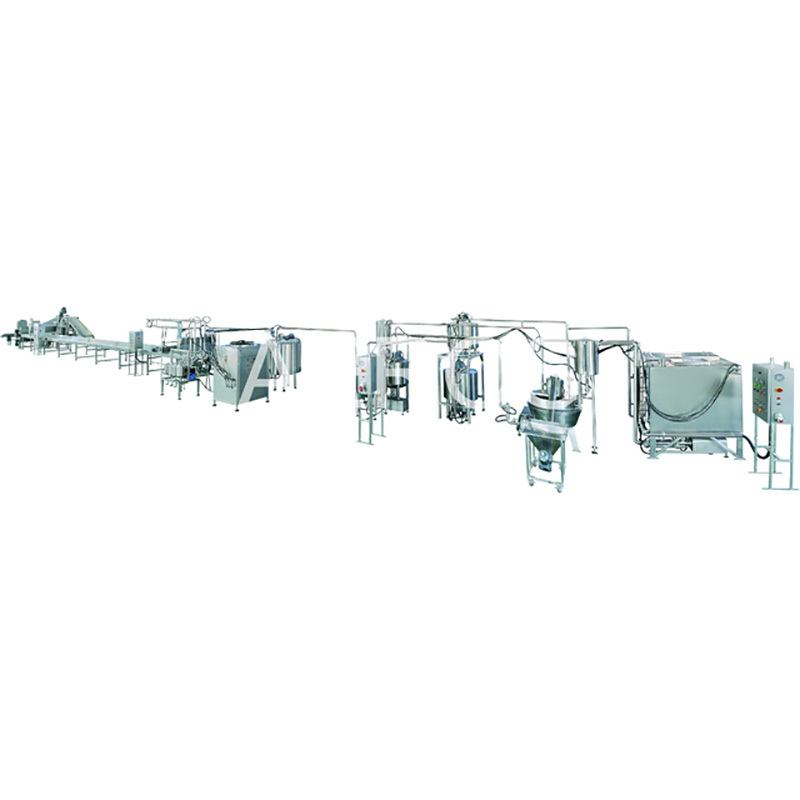

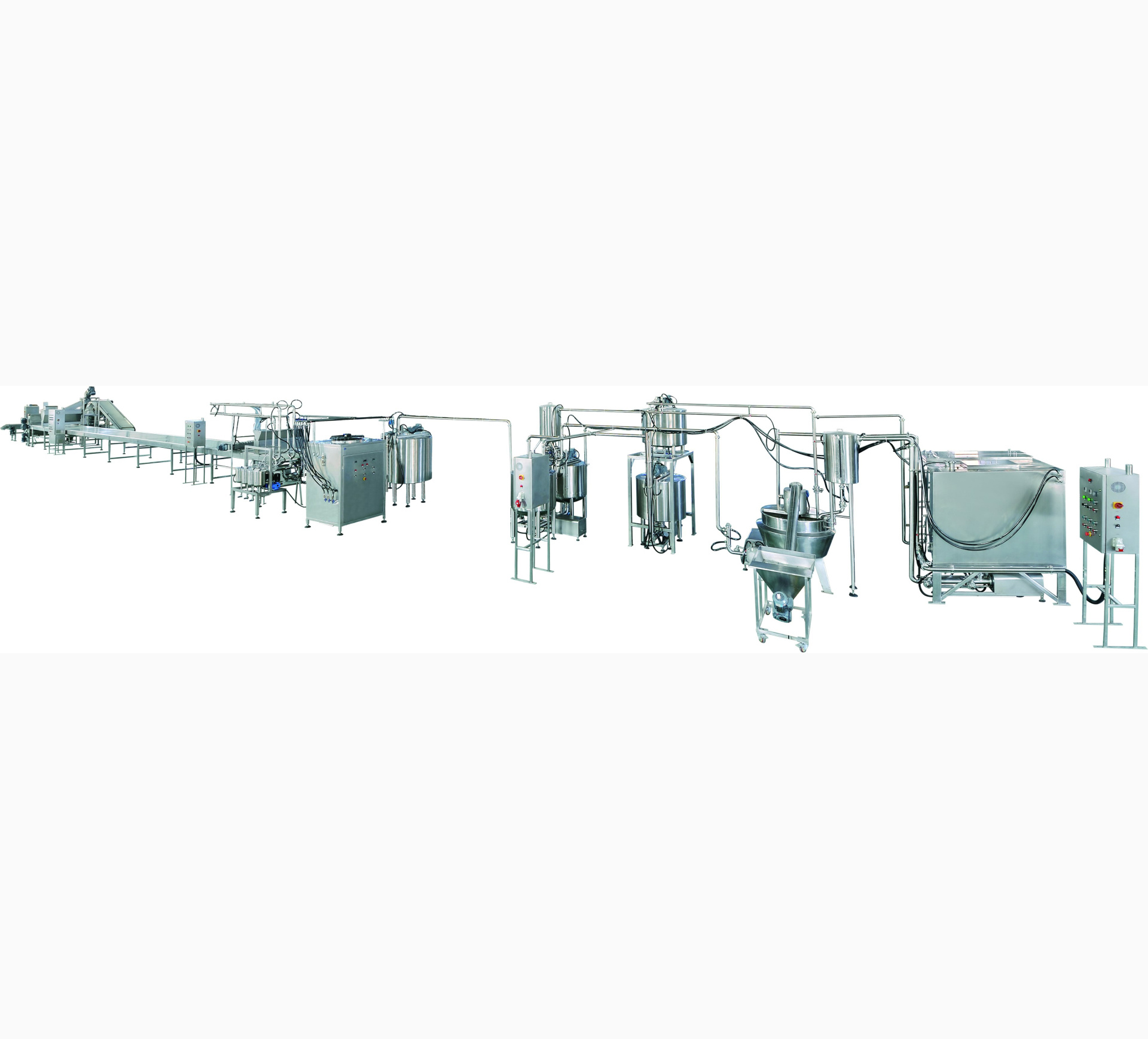

The cake production process has traditionally been labor-intensive, requiring substantial manual effort and time. However, the advent of fancy cake production systems has revolutionized how bakeries operate. These systems incorporate advanced technology that automates various stages of cake production, from mixing and baking to decorating and packaging. This not only streamlines the process but also enhances the quality of the final products.

Key Benefits of a Fancy Cake Production System

Implementing a fancy cake production system offers a myriad of benefits. Here are some of the most significant advantages:

1. Streamlined Operations

By automating routine tasks, bakeries can significantly reduce the time and labor required for cake production. This leads to a more streamlined operation, allowing staff to focus on higher-value activities such as product development and customer service.

2. Enhanced Product Consistency

With advanced mixing and baking technologies, bakeries can achieve uniformity in their cake products. This consistency is crucial for building customer trust and brand loyalty, as consumers expect the same taste and quality with every purchase.

3. Increased Production Capacity

Fancy cake production systems can handle large volumes of production without compromising quality. This enables bakeries to meet high demand, especially during peak seasons, without the need for additional labor.

4. Improved Quality Control

These systems often come equipped with built-in quality control features that monitor critical parameters throughout the production process. This ensures that every cake meets the desired standards, reducing waste and improving overall product quality.

5. Innovation and Creativity

Advanced cake production systems allow bakers to experiment with new flavors, designs, and techniques. With automated processes, bakers can focus on creativity rather than repetitive tasks, leading to a more innovative product line.

Enhancing Efficiency in Cake Production

Efficiency is one of the foremost advantages of a fancy cake production system. Traditional cake-making methods often involve numerous manual steps that can slow down the production line. With automation, bakeries can optimize each stage of the process.

Automated Mixing and Baking

Automated mixers can achieve precise measurements and consistent mixing times, ensuring that cake batter is uniform. Furthermore, sophisticated baking ovens can regulate temperatures and cooking times accurately, eliminating the guesswork often involved in baking.

Streamlined Decorating Processes

Modern cake production systems often feature automated decorating machines that can apply icing and decorations with precision. This not only speeds up the decorating process but also enhances the visual appeal of the cakes.

Achieving Consistency in Quality and Taste

One of the main challenges bakeries face is maintaining consistency across their product range. A fancy cake production system addresses this challenge effectively.

Precision in Ingredients

Automated systems ensure that every ingredient is measured accurately, which is essential for maintaining flavor profiles and textures. This level of precision minimizes variations in taste and quality.

Uniform Baking Conditions

With advanced baking equipment, ovens can maintain consistent heat levels, ensuring that every cake bakes evenly. This uniformity is critical for achieving the desired texture and moisture content.

Fostering Creativity with Advanced Technology

While efficiency and consistency are vital, creativity is what sets a bakery apart in a crowded market. Fancy cake production systems enable bakers to unleash their creative potential.

Innovative Cake Designs

With the aid of cutting-edge technology, bakers can experiment with intricate designs and unique flavor combinations. Automated decorating tools can replicate complex patterns and designs that would be time-consuming to achieve manually.

Expanding Flavor Profiles

Advanced mixing technology allows for the incorporation of diverse ingredients and flavors, leading to innovative cake recipes that can appeal to a broader customer base. From gluten-free to vegan options, bakeries can cater to various dietary preferences.

Boosting Profitability through Increased Production

Ultimately, the goal of any bakery is to increase profitability. A fancy cake production system can significantly contribute to this objective.

Reduced Labor Costs

By automating labor-intensive tasks, bakeries can reduce labor costs without sacrificing quality. This allows staff to focus on higher-value activities, improving overall productivity.

Higher Sales Volumes

The ability to produce cakes more quickly and efficiently enables bakeries to meet higher demand, especially during festive seasons and special events. This leads to increased sales volumes and revenue.

Lower Waste Levels

With improved quality control measures and precise ingredient measurements, bakeries can reduce waste significantly. This not only contributes to cost savings but also aligns with sustainability goals.

Steps to Implement a Cake Production System

Transitioning to a fancy cake production system involves several key steps:

1. Assess Your Needs

Evaluate your current production processes to identify areas for improvement and determine the specific features you need in a cake production system.

2. Research Available Systems

Explore various cake production systems on the market, comparing features, costs, and customer reviews to find the best fit for your bakery.

3. Plan for Integration

Consider how the new system will integrate with your existing equipment and workflow. A well-planned integration process will minimize disruptions during the transition.

4. Train Your Staff

Invest in training your staff on how to use the new system effectively. This will ensure that you maximize the benefits of the technology and maintain high standards of quality.

5. Monitor Performance

After implementation, closely monitor the system’s performance to identify any areas for further optimization. Continuous improvement is key to leveraging the full potential of your fancy cake production system.

Overcoming Challenges in Transitioning to a Fancy Cake Production System

While the advantages of a fancy cake production system are compelling, bakeries may face challenges during the transition.

Resistance to Change

Staff may be resistant to adopting new technology. Address this by highlighting the benefits and providing comprehensive training to ease the transition.

Initial Investment Costs

High initial costs can deter some bakeries. However, it’s essential to view this as an investment in the future of your business that can lead to significant long-term savings and increased profits.

Technical Issues

Like any technology, fancy cake production systems may encounter technical issues. Ensure you have a reliable support system in place to address any problems promptly.

Conclusion: The Future of Bakery Operations

In conclusion, a fancy cake production system offers bakeries a multitude of advantages, including enhanced efficiency, consistency, creativity, and profitability. As the bakery industry continues to evolve, embracing advanced technology will be crucial for staying competitive and meeting the demands of today’s consumers. By investing in a sophisticated cake production system, bakeries can not only improve their operations but also create delightful, innovative products that captivate their customers.

Frequently Asked Questions

1. What is a fancy cake production system?

A fancy cake production system is an automated setup that streamlines various stages of cake production, including mixing, baking, decorating, and packaging, using advanced technology.

2. How does automation improve cake production?

Automation improves cake production by enhancing efficiency, consistency, and quality while reducing labor costs and production times.

3. Can a cake production system help with creativity?

Yes, it allows bakers to experiment with new designs and flavors while focusing on creative aspects rather than repetitive tasks.

4. What are the initial costs associated with implementing such a system?

Initial costs can vary based on the system's complexity and features. However, it is considered an investment that can lead to long-term savings and increased profits.

5. How can bakeries overcome challenges during the transition?

Bakeries can overcome challenges by providing staff training, emphasizing the benefits of the system, and ensuring reliable technical support.

fancy Cake production system

Previous Page