Why You Can't Afford to Ignore Advanced Marshmallow Aeration Technology

2025/07/20

Why You Can't Afford to Ignore Advanced Marshmallow Aeration Technology

Table of Contents

- Introduction to Marshmallow Aeration Technology

- Understanding Aeration in Food Processing

- Why Aeration Matters in Marshmallow Production

- Advanced Aeration Technologies in the Industry

- Key Benefits of Advanced Aeration Technology

- Improved Product Quality

- Increased Production Efficiency

- Fostering Innovation in Product Development

- Challenges in Implementing Aeration Technology

- Future Trends in Marshmallow Manufacturing

- Conclusion

- FAQs about Marshmallow Aeration Technology

Introduction to Marshmallow Aeration Technology

The confectionery industry is constantly evolving, with manufacturers seeking innovative solutions to improve product quality and operational efficiency. Among these advancements, **advanced marshmallow aeration technology** has emerged as a game-changer, fundamentally altering how marshmallows are produced. By incorporating sophisticated aeration techniques, manufacturers can achieve superior texture, enhanced stability, and increased product appeal. This article delves into the importance of advanced marshmallow aeration technology and why it is essential for businesses to adapt to these innovations.

Understanding Aeration in Food Processing

Aeration refers to the process of incorporating air or gas into a mixture, thereby altering its physical properties. In the context of food processing, particularly in the production of confections like marshmallows, aeration plays a critical role in determining the texture, taste, and overall quality of the final product. Through aeration, manufacturers can create light, fluffy, and delightful marshmallow treats that appeal to a wide range of consumers.

Why Aeration Matters in Marshmallow Production

The marshmallow-making process involves several key steps: mixing, cooking, whipping, and cooling. Each of these stages can be significantly enhanced by effective aeration. Proper aeration not only affects the final product’s texture but also influences other crucial aspects, such as moisture retention and shelf life.

Texture and Mouthfeel

Aeration contributes to the characteristic chewiness and softness of marshmallows. By optimizing aeration techniques, manufacturers can produce marshmallows with the desired texture, which is vital for consumer satisfaction.

Moisture Management

Effective aeration helps in trapping moisture within the marshmallow, preventing it from drying out. This leads to a fresher product that maintains its quality over time, which is essential for commercial success.

Flavor Binding

Certain aeration techniques can enhance the binding of flavors and sweeteners, resulting in a more flavorful marshmallow. This is crucial in a competitive market where taste is a key differentiator.

Advanced Aeration Technologies in the Industry

With the continuous growth of food technology, various advanced aeration methods are being employed in marshmallow production. These innovations have not only improved efficiency but also enhanced the quality of the end product.

Mechanical Aeration Techniques

Mechanical aeration involves the use of specialized equipment to create air bubbles within the marshmallow mixture. This method often includes the use of **high-shear mixers** and **whipping machines** that can efficiently introduce air into the mixture, resulting in a light and fluffy texture.

Gas Injection Aeration

Gas injection aeration takes the process a step further by using gases such as nitrogen or carbon dioxide to create a unique texture and enhance stability. This method allows manufacturers to control the size and distribution of air bubbles more precisely, leading to a more consistent product.

Key Benefits of Advanced Aeration Technology

Implementing advanced marshmallow aeration technology can yield significant benefits for manufacturers. Understanding these advantages can help businesses make informed decisions about their production processes.

Improved Product Quality

The most apparent benefit of advanced aeration technology is the improvement in product quality. By utilizing sophisticated aeration methods, manufacturers can achieve a more consistent texture and flavor profile, resulting in a superior marshmallow product.

Increased Production Efficiency

Modern aeration systems are designed to optimize production processes, reducing the time and labor required for mixing and whipping. This leads to increased productivity and ultimately higher profit margins for manufacturers.

Fostering Innovation in Product Development

With advanced aeration technology, manufacturers can experiment with new flavors, textures, and formulations. This flexibility fosters innovation and allows businesses to meet evolving consumer demands, keeping them competitive in the market.

Challenges in Implementing Aeration Technology

Despite the numerous benefits, there are challenges associated with the implementation of advanced marshmallow aeration technology. Understanding these challenges is crucial for manufacturers looking to adopt new systems.

Cost of Technology

The initial investment in advanced aeration technology can be significant. Manufacturers must weigh the long-term benefits against the upfront costs to determine if the investment is worthwhile.

Training and Expertise

New technologies often require specialized training for staff. Ensuring that personnel are adequately trained to operate and maintain new aeration systems is essential for maximizing the benefits of the technology.

Integration with Existing Processes

Implementing new aeration systems can sometimes disrupt existing production processes. Manufacturers must develop strategies to integrate these technologies smoothly to avoid downtimes and inefficiencies.

Future Trends in Marshmallow Manufacturing

As the confectionery industry continues to evolve, several trends are emerging in marshmallow production. These trends are largely driven by consumer preferences, technological advancements, and sustainability initiatives.

Health-Conscious Products

With a rising consumer focus on health and wellness, there is an increasing demand for healthier marshmallow options. Manufacturers are exploring ways to reduce sugar content and incorporate natural ingredients without compromising taste or texture.

Sustainability Initiatives

Sustainability is becoming a priority for many consumers. Manufacturers are investigating eco-friendly packaging options and sustainable sourcing of ingredients, which can be enhanced by advanced aeration techniques that optimize ingredient usage.

Customization and Personalization

The growing trend of customization in food products is prompting manufacturers to develop more personalized marshmallow options. Advanced aeration technology can facilitate the creation of unique flavors and textures tailored to individual consumer preferences.

Conclusion

In conclusion, advanced marshmallow aeration technology is not just a trend—it is a necessity for modern confectionery manufacturers looking to enhance product quality, improve production efficiency, and foster innovation. As the industry continues to evolve, businesses that embrace these technologies will not only stay competitive but also meet the changing demands of consumers. Ignoring this critical aspect of marshmallow production could result in missed opportunities and a decline in market relevance.

FAQs about Marshmallow Aeration Technology

1. What is marshmallow aeration technology?

Marshmallow aeration technology involves methods to incorporate air or gas into marshmallow mixtures, enhancing the texture, flavor, and stability of the final product.

2. How does aeration affect marshmallow texture?

Aeration creates air pockets within the marshmallow, leading to a light, fluffy texture that is essential for consumer satisfaction.

3. Are there different methods of aeration?

Yes, there are several aeration methods, including mechanical aeration and gas injection techniques, each offering unique benefits and results.

4. What are the cost implications of advanced aeration technology?

While initial costs can be high, advanced aeration technology often leads to increased efficiency and improved product quality, making it a worthwhile investment in the long run.

5. How can manufacturers adapt to consumer trends using aeration technology?

By utilizing advanced aeration techniques, manufacturers can experiment with healthier ingredients and unique flavors, aligning their products with evolving consumer preferences.

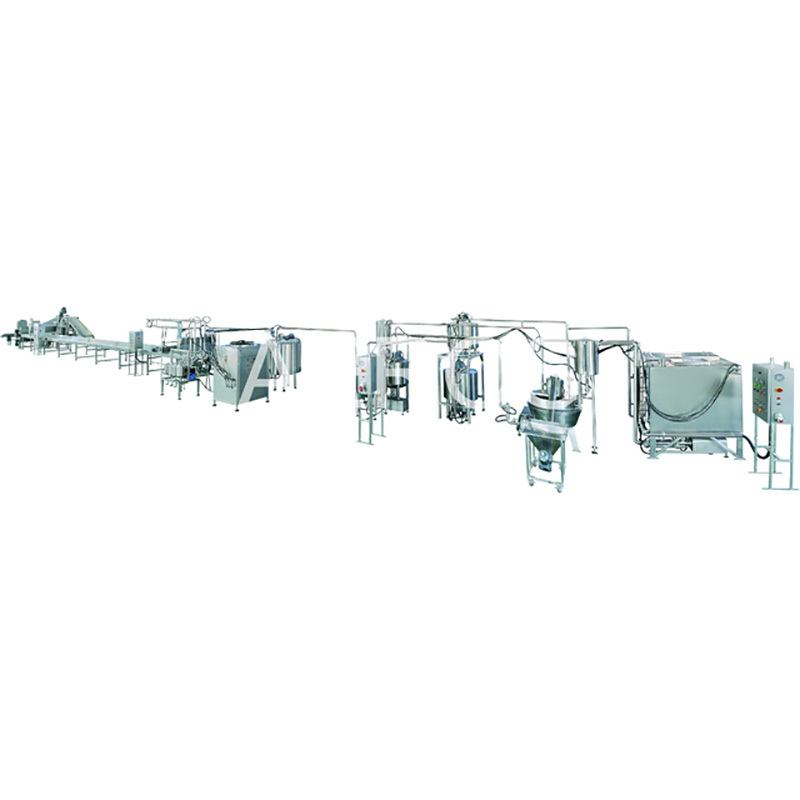

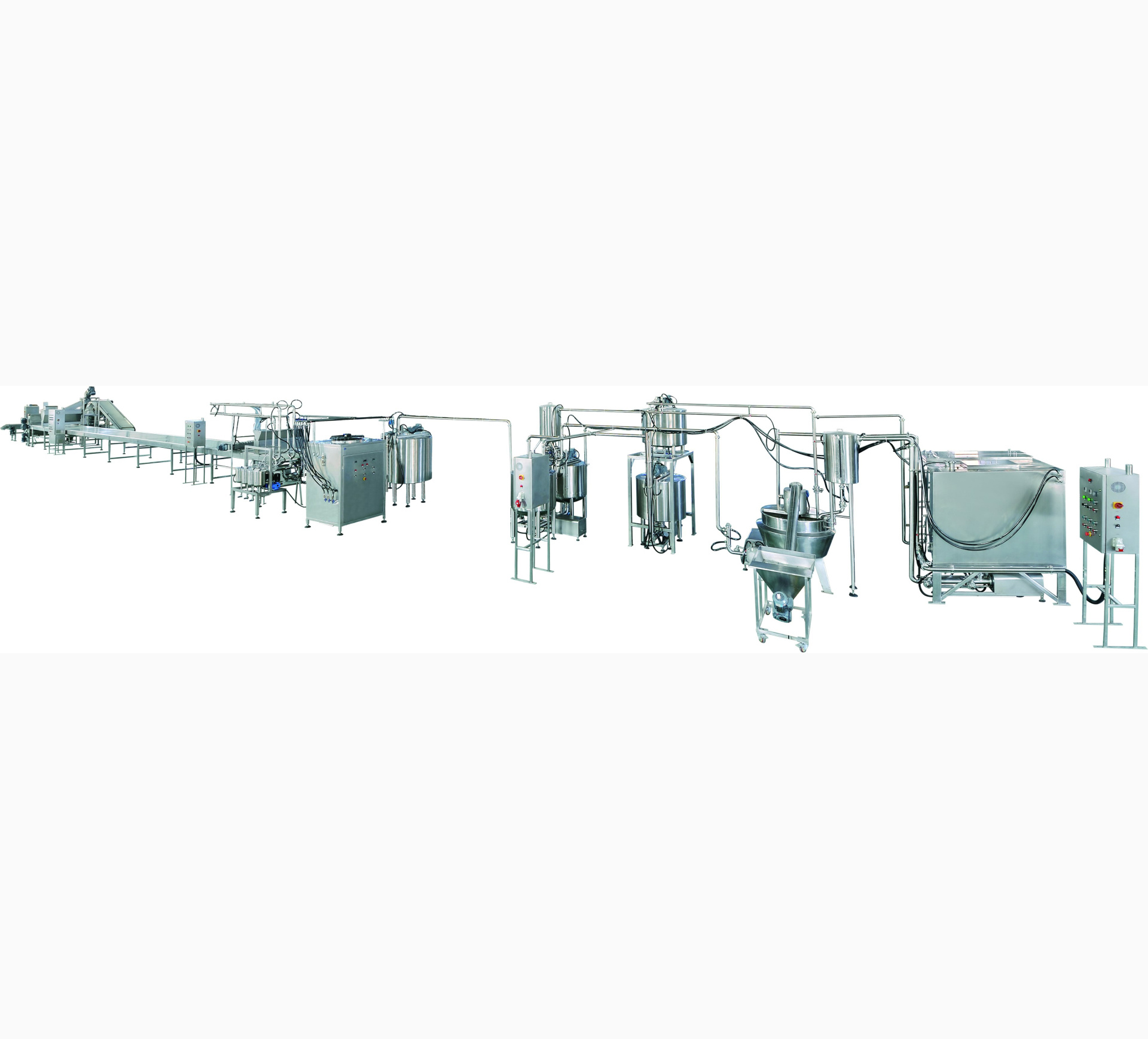

advanced Marshmallow aeration machine

Previous Page