Unlocking the Secrets of Aerated Chocolate Production Line Efficiency

2025/06/30

Unlocking the Secrets of Aerated Chocolate Production Line Efficiency

Table of Contents

- Understanding Aerated Chocolate Production

- The Importance of Production Line Efficiency

- Key Components of an Aerated Chocolate Production Line

- Best Practices for Optimizing Production Efficiency

- Technology Solutions for Enhanced Production Efficiency

- Quality Control in Aerated Chocolate Production

- Sustainability in Food and Beverage Manufacturing

- Future Trends in Aerated Chocolate Production

- Frequently Asked Questions

- Conclusion

Understanding Aerated Chocolate Production

Aerated chocolate refers to a unique class of chocolate that is infused with air, resulting in a lighter texture and a distinctive mouthfeel. The process of creating aerated chocolate involves incorporating air bubbles into the chocolate mixture, which is achieved through various methods such as whipping, spinning, or injecting. This technique not only enhances the sensory experience but also allows for innovative product development. Understanding the fundamentals of this production process is crucial for manufacturers aiming to optimize efficiency and maintain product quality.

The Process of Aeration in Chocolate

Aeration is a critical step in the production of aerated chocolate. Manufacturers use specialized equipment to introduce air into the chocolate mixture, which can alter the density and texture. Techniques such as **foaming**, **whipping**, or **using nitrogen gas** are commonly employed. Each method requires precise control over temperature, timing, and ingredient proportions to achieve the desired consistency and flavor profile.

Ingredients Used in Aerated Chocolate Production

The primary ingredient in aerated chocolate is high-quality cocoa mass, often combined with sugar, milk powder, and emulsifiers such as lecithin. The right balance of these ingredients is essential for achieving the perfect aeration and texture. Additionally, incorporating **flavor enhancers** and **stabilizers** can significantly influence the final product’s quality and shelf life.

The Importance of Production Line Efficiency

Efficiency in the production line is pivotal for maintaining competitiveness in the food and beverage industry. High efficiency directly correlates with reduced operational costs, increased output, and improved product quality. Manufacturers who invest in optimizing their production lines can capitalize on these benefits, which will ultimately enhance profitability and customer satisfaction.

Reducing Waste and Increasing Productivity

A streamlined production line minimizes waste, whether through excess raw material use or time lost in inefficient processes. Techniques such as the **just-in-time (JIT)** inventory system can help to synchronize production with demand, reducing the need for large stockpiles of raw materials. Additionally, implementing regular maintenance schedules can prevent breakdowns and minimize downtime.

Improving Product Quality

High production efficiency must not compromise product quality. By focusing on quality control during production, manufacturers can ensure that aerated chocolate meets consumer expectations. This includes regular sensory evaluations and physical tests to monitor texture, flavor, and shelf stability.

Key Components of an Aerated Chocolate Production Line

Understanding the essential components of an aerated chocolate production line is fundamental for optimizing efficiency. Each part of the line must work in harmony to ensure smooth operations.

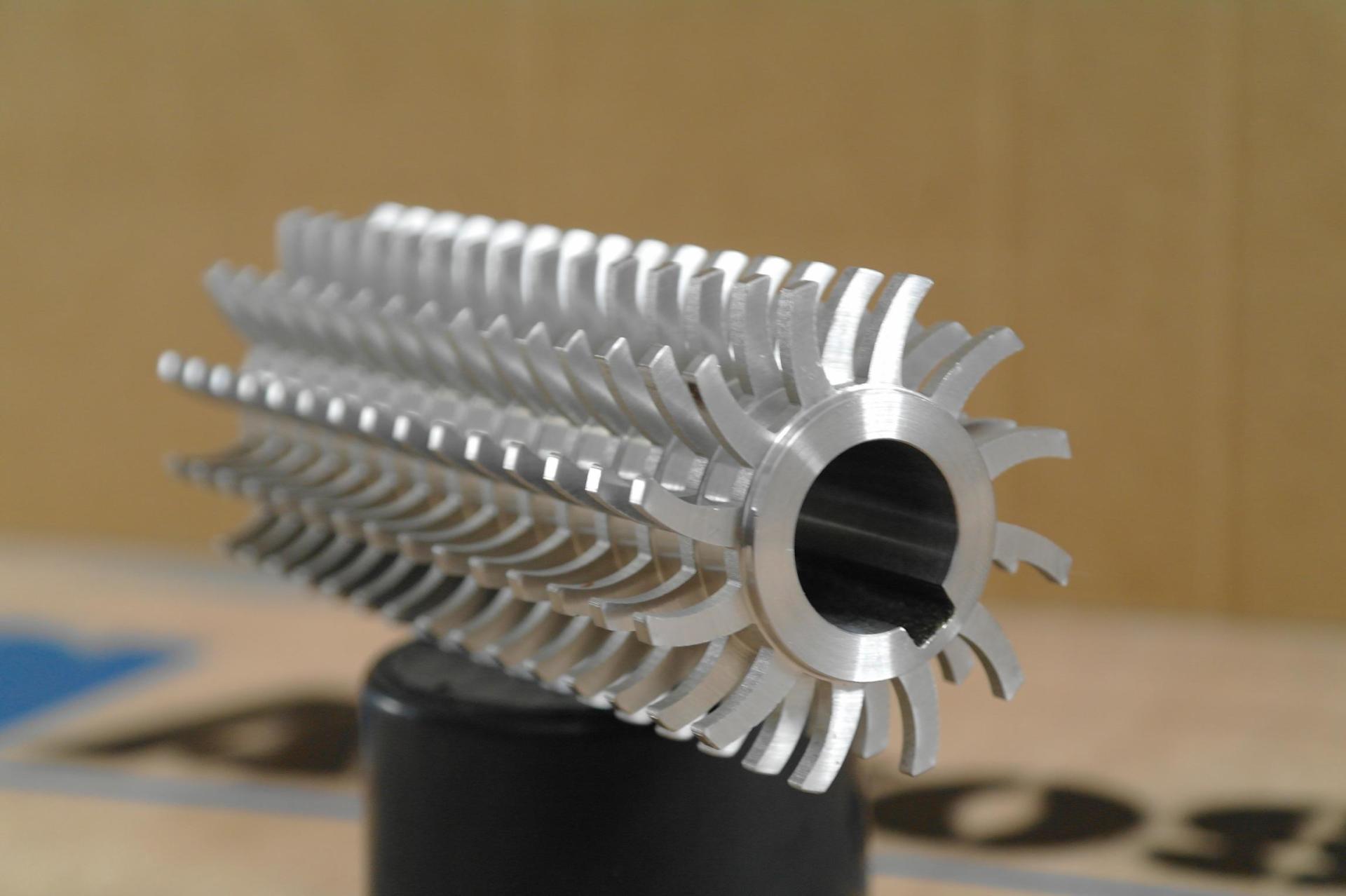

Mixers and Emulsifiers

Mixers play a vital role in creating a homogenous chocolate mixture. Advanced mixers equipped with emulsifiers help to achieve the desired texture by evenly distributing air and other ingredients. The choice of mixer can significantly impact the aeration process, making it crucial to select equipment that suits the specific production needs.

Cooling and Tempering Units

After aeration, chocolate must be cooled and tempered correctly to maintain its structure and prevent blooming. Efficient cooling systems ensure rapid temperature reduction, which is essential for achieving the ideal crystal structure in chocolate.

Packaging Machinery

Packaging is the final step in the production process, and efficient packaging machinery can help reduce bottlenecks. Automated packaging solutions improve speed and accuracy, enhancing overall productivity. Additionally, investing in sustainable packaging materials can resonate well with eco-conscious consumers.

Best Practices for Optimizing Production Efficiency

To maximize the efficiency of the aerated chocolate production line, consider implementing these best practices.

Regular Training and Upskilling of Staff

A skilled workforce is essential for maintaining high efficiency. Regular training programs can ensure that employees are up-to-date with the latest production techniques and machinery. Upskilling staff not only enhances productivity but also fosters a culture of continuous improvement.

Implementing Lean Manufacturing Principles

Lean manufacturing focuses on minimizing waste while maximizing productivity. By analyzing each step in the production process, manufacturers can identify areas for improvement. Techniques such as **value stream mapping** can help visualize processes and highlight inefficiencies.

Utilizing Data Analytics

In the digital age, data analytics can provide valuable insights into production processes. Employing software to monitor real-time data can help identify trends, predict maintenance needs, and analyze production efficiency. This proactive approach allows for swift adjustments to enhance overall effectiveness.

Technology Solutions for Enhanced Production Efficiency

Advancements in technology have revolutionized the food and beverage manufacturing industry. Leveraging these innovations can significantly improve production line efficiency.

Automation and Robotics

Automated systems and robotics can streamline repetitive tasks, reducing human error and increasing production speed. From mixing to packaging, automation can enhance efficiency while allowing staff to focus on more value-added activities.

Smart Manufacturing and Industry 4.0

Embracing **Industry 4.0** concepts can lead to smarter manufacturing processes. This includes integrating IoT devices that provide real-time data on machinery performance, enabling predictive maintenance and reducing downtime.

Quality Control in Aerated Chocolate Production

Maintaining consistent quality in aerated chocolate production is crucial for customer satisfaction. Implementing rigorous quality control measures throughout the production process can prevent defects and ensure the final product meets industry standards.

Monitoring Raw Material Quality

The quality of raw materials directly influences the final product. Regular testing and sourcing from reputable suppliers can enhance the overall quality of aerated chocolate.

In-Process Quality Checks

Establishing quality checkpoints throughout the production process ensures any deviations from standards are detected early. This might include monitoring temperature, viscosity, and texture during aeration.

Sustainability in Food and Beverage Manufacturing

Sustainability has become a critical focus in the food and beverage industry. Manufacturers are increasingly seeking ways to reduce their environmental impact while maintaining efficiency.

Reducing Energy Consumption

Implementing energy-efficient machinery and optimizing production processes can lead to significant reductions in energy consumption. Utilizing renewable energy sources, such as solar or wind power, can further enhance sustainability efforts.

Waste Reduction Initiatives

Establishing waste reduction initiatives can minimize the environmental footprint of production. This includes recycling packaging materials and repurposing by-products from the chocolate-making process.

Future Trends in Aerated Chocolate Production

As the food and beverage industry evolves, so do the trends shaping aerated chocolate production. Staying ahead of these trends can provide manufacturers with a competitive edge.

Personalization and Customization

Consumers are increasingly seeking personalized products. Manufacturers may explore innovative methods to create customized aerated chocolate varieties to cater to specific consumer preferences.

Health-Conscious Options

With a growing focus on health, there is a rising demand for healthier chocolate options. This trend may lead to the development of aerated chocolates with reduced sugar, organic ingredients, or added nutrients.

Frequently Asked Questions

What is aerated chocolate?

Aerated chocolate is a type of chocolate that incorporates air bubbles, resulting in a lighter texture and unique mouthfeel.

How can I improve my production line efficiency?

Improving production line efficiency can be achieved through regular staff training, implementing lean manufacturing principles, and utilizing data analytics for insight into operations.

What technologies can enhance chocolate production?

Technologies such as automation, robotics, and IoT devices can streamline production processes, reduce human error, and enable predictive maintenance.

What role does quality control play in chocolate production?

Quality control ensures that raw materials and production processes meet industry standards, which is essential for maintaining product consistency and customer satisfaction.

How can I make my production more sustainable?

Sustainability can be enhanced by reducing energy consumption, implementing waste reduction initiatives, and sourcing materials from sustainable suppliers.

Conclusion

Unlocking the secrets of aerated chocolate production line efficiency requires a multifaceted approach that encompasses understanding aeration processes, optimizing production components, and implementing best practices. By embracing technological advancements and focusing on quality control, manufacturers can elevate their production capabilities while adhering to sustainability principles. The future of aerated chocolate is bright, and those who adapt to evolving consumer demands and industry trends will undoubtedly lead the way in this dynamic market.

Aerated chocolate production line

Previous Page