The Art and Science of Cake Production: A Comprehensive Guide for Food Processing Professionals

2025/06/29

Cake production is a fascinating blend of art and science, playing a crucial role in the food processing industry. Understanding the intricacies of producing cakes can significantly enhance your operations and yield superior products. This article will delve into the essential aspects of cake production, including the types of machinery used, the manufacturing process, and best practices to ensure quality.

The first step in cake production is ingredient preparation, which includes selecting high-quality raw materials such as flour, sugar, eggs, and flavorings. The right balance of these ingredients is vital, as they directly influence the cake's texture, taste, and overall appeal. In modern facilities, food processing machinery is designed to automate ingredient handling, ensuring consistency and efficiency.

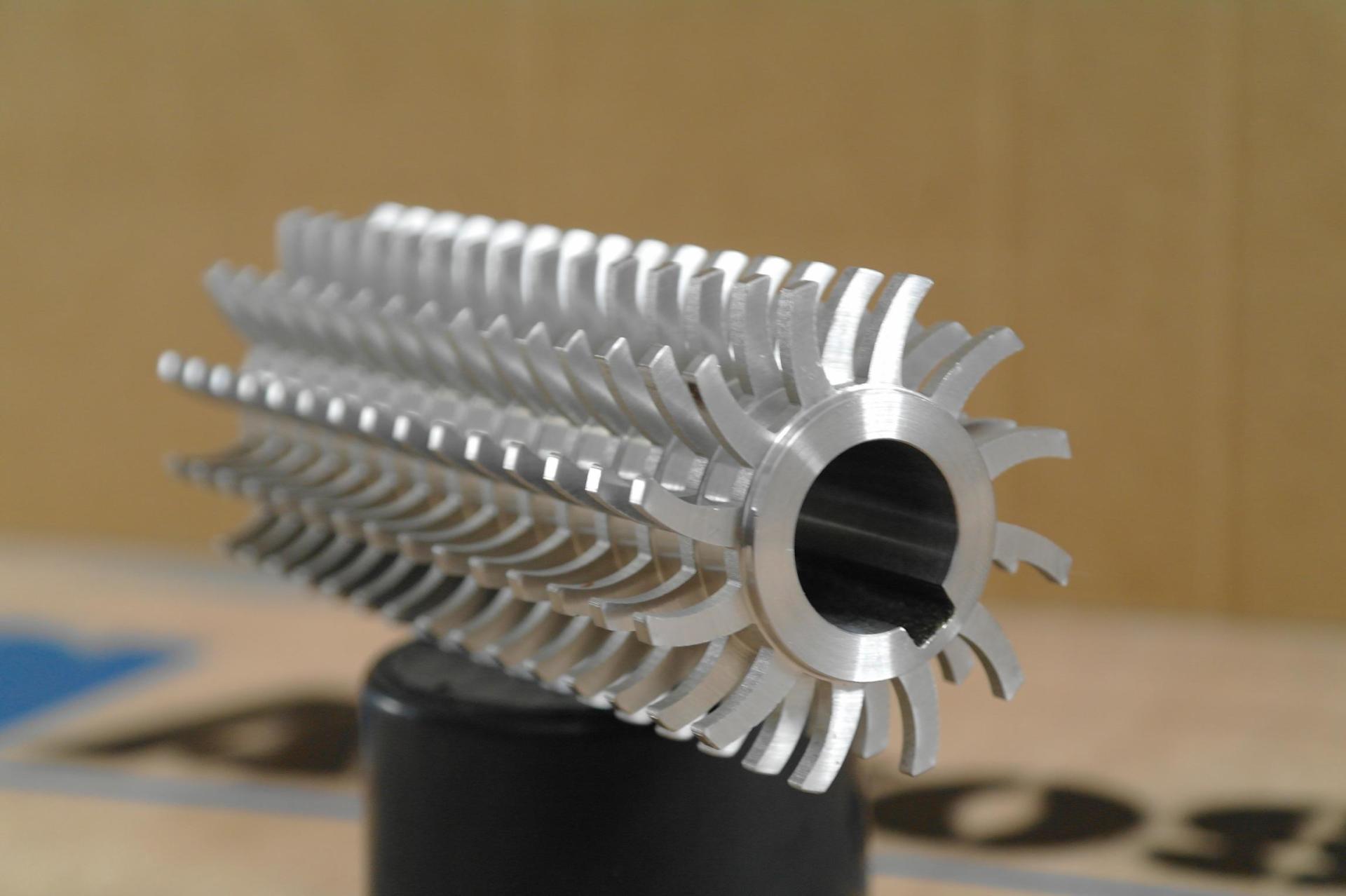

Once the ingredients are prepared, they are mixed using specialized mixing equipment. This machinery varies in size and complexity, from small, portable mixers for artisanal bakeries to large-scale mixers capable of handling extensive batch production. The mixing process is crucial as it not only combines the ingredients but also incorporates air into the batter, contributing to the desired cake texture.

After mixing, the batter is poured into cake molds, which can be made from various materials such as metal or silicone. The choice of mold impacts the baking process and the final product’s appearance. Baking ovens play a crucial role in cake production, with options ranging from conventional batch ovens to high-efficiency continuous baking systems. The temperature and baking time must be precisely controlled to ensure even baking and prevent issues like sinking or uneven texture.

Once the cakes are baked, they undergo cooling, an essential step that prevents moisture loss and ensures the cakes maintain their structure. Cooling tunnels or racks are used in larger operations to streamline this process. After cooling, cakes can be decorated or layered, depending on the final product specifications.

Quality control is paramount in cake production. Implementing strict quality assurance protocols can help identify any inconsistencies in texture, flavor, or appearance. Regular maintenance of machinery is also crucial, as it ensures optimal operation and reduces the risk of production delays.

In conclusion, mastering cake production requires a combination of high-quality ingredients, efficient machinery, and attention to detail throughout the manufacturing process. By understanding these elements, food processing professionals can enhance their production capabilities and deliver exceptional cakes that meet consumer expectations. Embracing innovation and efficiency in your production line will ultimately lead to improved product quality and customer satisfaction.

The first step in cake production is ingredient preparation, which includes selecting high-quality raw materials such as flour, sugar, eggs, and flavorings. The right balance of these ingredients is vital, as they directly influence the cake's texture, taste, and overall appeal. In modern facilities, food processing machinery is designed to automate ingredient handling, ensuring consistency and efficiency.

Once the ingredients are prepared, they are mixed using specialized mixing equipment. This machinery varies in size and complexity, from small, portable mixers for artisanal bakeries to large-scale mixers capable of handling extensive batch production. The mixing process is crucial as it not only combines the ingredients but also incorporates air into the batter, contributing to the desired cake texture.

After mixing, the batter is poured into cake molds, which can be made from various materials such as metal or silicone. The choice of mold impacts the baking process and the final product’s appearance. Baking ovens play a crucial role in cake production, with options ranging from conventional batch ovens to high-efficiency continuous baking systems. The temperature and baking time must be precisely controlled to ensure even baking and prevent issues like sinking or uneven texture.

Once the cakes are baked, they undergo cooling, an essential step that prevents moisture loss and ensures the cakes maintain their structure. Cooling tunnels or racks are used in larger operations to streamline this process. After cooling, cakes can be decorated or layered, depending on the final product specifications.

Quality control is paramount in cake production. Implementing strict quality assurance protocols can help identify any inconsistencies in texture, flavor, or appearance. Regular maintenance of machinery is also crucial, as it ensures optimal operation and reduces the risk of production delays.

In conclusion, mastering cake production requires a combination of high-quality ingredients, efficient machinery, and attention to detail throughout the manufacturing process. By understanding these elements, food processing professionals can enhance their production capabilities and deliver exceptional cakes that meet consumer expectations. Embracing innovation and efficiency in your production line will ultimately lead to improved product quality and customer satisfaction.

Cake production

Previous Page