Unlocking the Benefits of a Cake Continuous Aeration System: Revolutionizing Food Processing Efficiency

2025/06/26

Unlocking the Benefits of a Cake Continuous Aeration System

Table of Contents

- Introduction to Cake Continuous Aeration Systems

- What is a Cake Continuous Aeration System?

- How Does Continuous Aeration Work?

- Benefits of Continuous Aeration in Food Processing

- Applications of Cake Continuous Aeration Systems

- Technological Advancements in Aeration Systems

- Case Studies: Success Stories in the Industry

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Cake Continuous Aeration Systems

In the food and beverage processing industry, achieving the perfect texture and flavor is crucial. Cake Continuous Aeration Systems have emerged as an innovative solution, transforming how manufacturers produce high-quality baked goods. By incorporating advanced aeration technology, this system offers numerous benefits that can enhance efficiency, product quality, and overall production processes.

What is a Cake Continuous Aeration System?

A Cake Continuous Aeration System is designed to introduce air into cake batter in a controlled manner. Unlike traditional aeration methods that rely on intermittent mixing, this system allows for a steady influx of air throughout the mixing process. This continuous aeration not only improves the incorporation of air but also ensures uniform distribution, resulting in a lighter, fluffier cake texture.

Key Components of the System

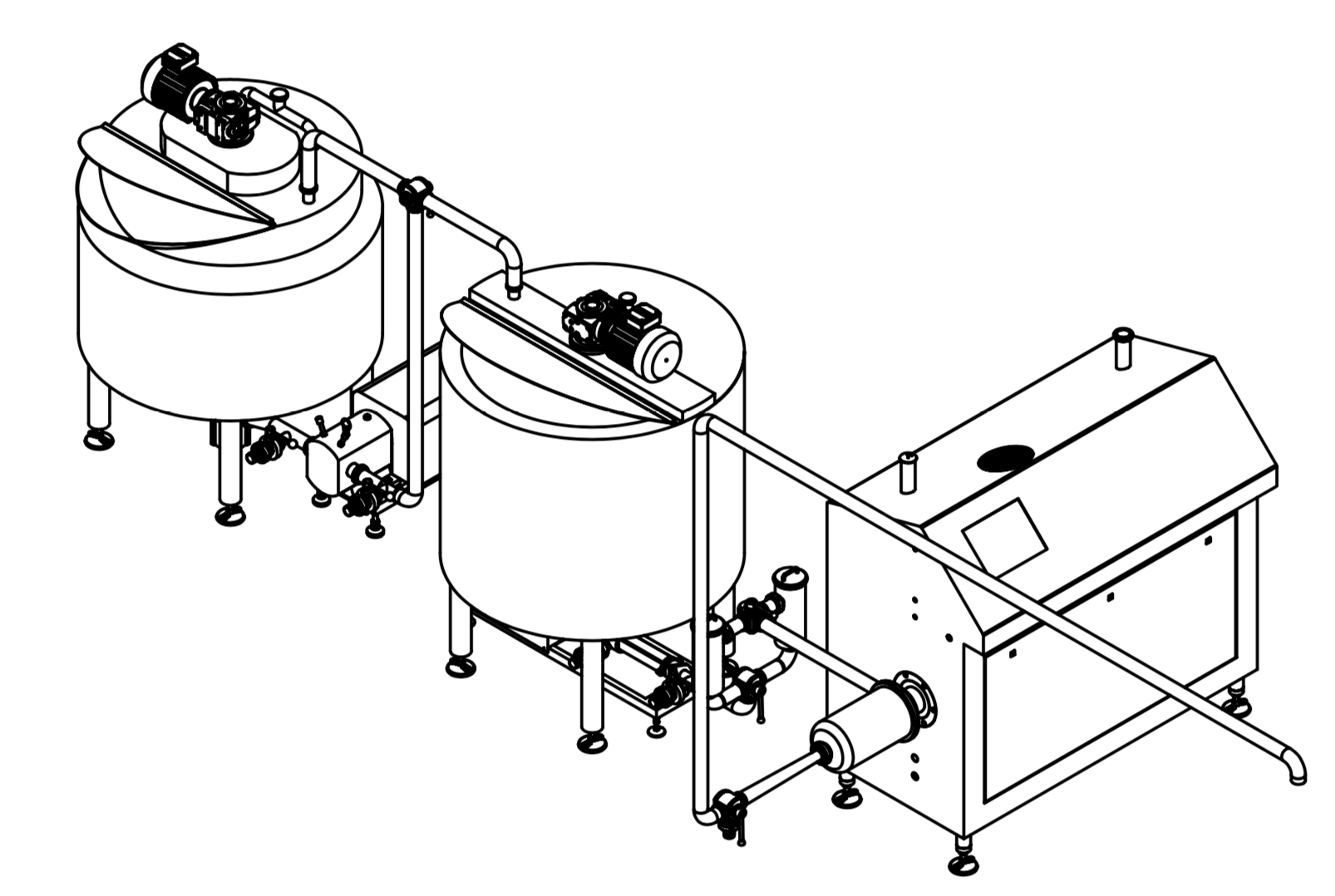

The Cake Continuous Aeration System comprises several key components, including:

- **Aerators**: Specialized devices that introduce air into the batter.

- **Mixing Chambers**: Where the batter and air combine for optimal aeration.

- **Control Systems**: Monitors and regulates air flow and mixing speed for consistent results.

How Does Continuous Aeration Work?

The operational efficiency of a Cake Continuous Aeration System lies in its ability to maintain a constant air flow during the mixing process. The aerators draw in ambient air and inject it into the batter at calculated intervals. This process reduces the formation of large air bubbles, which can create an uneven texture in baked goods.

The Mixing Process

1. **Preparation**: Ingredients such as flour, sugar, and eggs are measured and fed into the mixing chamber.

2. **Continuous Aeration**: Air is continuously injected into the mixture as it is blended, allowing for gradual incorporation, which enhances the final product's structure.

3. **Monitoring**: Advanced sensors measure the viscosity and density of the batter, adjusting the aeration rate accordingly for optimal results.

Benefits of Continuous Aeration in Food Processing

Implementing a Cake Continuous Aeration System offers several significant advantages:

1. Improved Texture and Quality

The gentle incorporation of air leads to a lighter crumb structure in cakes, resulting in a superior texture that enhances the overall eating experience.

2. Increased Production Efficiency

With continuous aeration, manufacturers can achieve a more consistent mix in a shorter amount of time, reducing the overall production cycle.

3. Flexibility in Product Development

The system allows for the easy adjustment of aeration levels, enabling the creation of various cake styles and flavors to meet market demands without requiring extensive retooling.

4. Cost-Effectiveness

By optimizing ingredient usage and reducing waste, manufacturers can significantly lower production costs while maintaining product quality.

5. Enhanced Shelf Life

Aerated cakes generally have a longer shelf life, thanks to improved moisture retention and reduced staling rates.

Applications of Cake Continuous Aeration Systems

The versatility of the Cake Continuous Aeration System allows its application across various sectors within the food and beverage industry.

Baked Goods Production

Cake manufacturers are the primary users of continuous aeration systems, benefiting from improved consistency and quality in their products.

Confectionery and Pastry Making

In the confectionery sector, these systems help create lighter, airier textures for pastries and cakes, elevating consumer enjoyment.

Industrial Scale Production

For large-scale producers, continuous aeration meets the demand for high-volume production without sacrificing quality.

Technological Advancements in Aeration Systems

The evolution of aeration technology is driven by advancements in engineering and materials science. Current trends include:

Smart Technology Integration

Modern Cake Continuous Aeration Systems often incorporate IoT capabilities, allowing manufacturers to monitor performance metrics in real-time, ensuring optimal operation.

Energy Efficiency

Newer models are designed to consume less energy while maintaining high levels of aeration, resulting in cost savings and a reduced carbon footprint.

Automation

Automation in aeration systems minimizes human error and enhances consistency, allowing manufacturers to focus on optimizing other aspects of production.

Case Studies: Success Stories in the Industry

Several industry leaders have successfully implemented Cake Continuous Aeration Systems, achieving remarkable results.

Case Study 1: Leading Cake Manufacturer

A major cake manufacturer reported a **30% increase** in production efficiency after integrating the continuous aeration system, alongside a significant reduction in ingredient costs.

Case Study 2: Artisan Bakery

An artisan bakery utilized the system to develop a new line of gourmet cakes, which received rave reviews for their light texture and extended freshness. This innovation helped increase sales by **25%** within the first year.

Frequently Asked Questions (FAQs)

1. What types of cakes benefit most from continuous aeration?

Continuous aeration systems are particularly beneficial for sponge cakes, chiffon cakes, and other light-textured baked goods that require significant air incorporation.

2. Can continuous aeration systems handle large-scale production?

Yes, these systems are designed for industrial-scale production, providing consistency and quality in high-volume baking operations.

3. How does continuous aeration affect flavor?

By improving the texture, continuous aeration enhances mouthfeel, which can positively influence the overall flavor perception of the cake.

4. What maintenance is required for these systems?

Regular maintenance includes cleaning aerators and mixing chambers, inspecting components for wear, and calibrating control systems to ensure accurate operation.

5. Are there any limitations to using continuous aeration systems?

While they offer numerous benefits, it’s essential to tailor the system to specific recipes and production needs to achieve optimal results.

Conclusion

The adoption of Cake Continuous Aeration Systems represents a significant advancement in food processing technology. By unlocking the benefits of continuous aeration, manufacturers can achieve improved texture, enhanced efficiency, and better product quality. As the industry continues to innovate, the role of these systems will undoubtedly become more critical in meeting consumer demands for high-quality baked goods. Embracing this technology not only positions manufacturers at the forefront of the food processing sector but also ensures they meet the evolving tastes and preferences of today’s discerning consumers.

Cake continuous aeration system

Previous Page