Exploring the Benefits of Automated Mousse Production Lines: Revolutionizing the Food and Beverage Industry

2026/02/19

Exploring the Benefits of Automated Mousse Production Lines

Introduction: The Rise of Automation in Food Processing

In recent years, the food and beverage industry has witnessed a significant shift towards automation. This transformation is particularly evident in the production of mousse, a popular dessert that requires precision and consistency. Automated mousse production lines are not only enhancing operational efficiency but also improving product quality and safety. In this article, we will explore the myriad benefits of these cutting-edge production systems.

The Importance of Mousse in the Food Industry

Mousse is a versatile dessert enjoyed by consumers worldwide. Its creamy texture and rich flavors make it a favorite in restaurants, catering services, and retail food outlets. The demand for mousse continues to grow, which necessitates efficient production methods to meet consumer expectations while maintaining quality.

Meeting Consumer Demand with Automation

As consumer preferences evolve, so does the need for manufacturers to adapt quickly. Automated mousse production lines enable producers to increase output without sacrificing quality. By utilizing automated systems, manufacturers can respond to market trends more effectively and maintain a competitive edge.

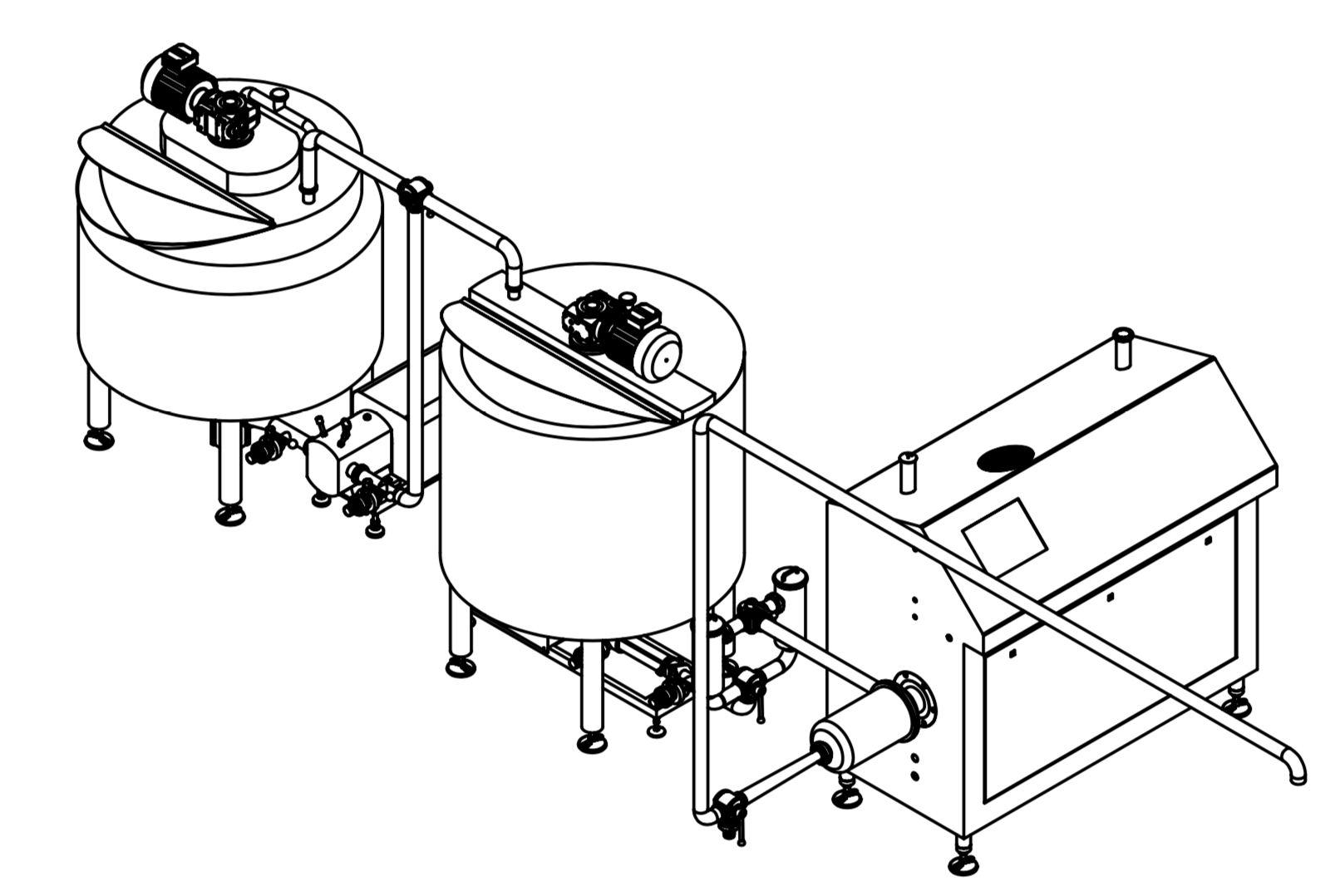

Key Components of Automated Mousse Production Lines

Understanding the components that make up an automated mousse production line is essential for appreciating its benefits. These systems typically consist of several key elements:

1. Ingredient Dispensing Systems

Automated ingredient dispensing ensures precise measurements of each component, including cream, sugar, and flavorings. This level of accuracy is crucial for maintaining consistency across batches.

2. Mixing and Whipping Equipment

The mixing process is critical for achieving the desired texture in mousse. Automated mixing and whipping equipment can adjust speed and duration based on the recipe, ensuring optimal results every time.

3. Cooling and Setting Mechanisms

Once the mousse is mixed, it must be cooled and set correctly. Automated cooling systems maintain the ideal temperature and conditions, reducing the risk of human error.

4. Packaging Solutions

Automated packaging systems streamline the final stage of production, ensuring that mousse is packaged efficiently and securely. This not only enhances shelf life but also improves presentation for retail.

Benefits of Automated Mousse Production Lines

The advantages of incorporating automated mousse production lines into a manufacturing facility are extensive.

1. Enhanced Efficiency and Productivity

Automation significantly boosts productivity. By reducing manual labor, production lines can operate continuously, producing higher volumes of mousse in less time. This efficiency translates into cost savings and increased profitability for manufacturers.

2. Consistent Quality and Taste

In food production, consistency is key. Automated systems minimize variability in ingredient measurements and mixing techniques, ensuring that every batch of mousse meets the same high standards. This reliability fosters customer loyalty and satisfaction.

3. Improved Food Safety and Compliance

Automated production lines often come equipped with advanced monitoring systems that track hygiene and safety protocols. This is essential for complying with food safety regulations, as it reduces the risk of contamination and ensures that the production environment meets high standards.

4. Cost Savings in Labor and Operational Expenses

While the initial investment in automated systems can be significant, the long-term savings in labor costs and operational efficiency often outweigh the initial costs. Fewer employees are needed for manual tasks, which can lead to substantial reductions in payroll expenses.

5. Flexibility and Scalability

Automated mousse production lines offer the flexibility to adapt to varying production demands. As consumer trends shift or new recipes are introduced, these systems can be reconfigured to meet new requirements without extensive downtime.

6. Sustainability and Environmental Impact

Automation can contribute to more sustainable manufacturing practices. By optimizing resource usage, reducing waste, and streamlining production processes, automated systems can significantly lower the environmental footprint of mousse production.

Challenges of Implementing Automated Mousse Production Lines

While the benefits of automation are significant, implementing these systems is not without challenges.

1. Initial Investment Costs

The upfront cost of purchasing and installing automated production lines can be substantial. Manufacturers must weigh these costs against potential long-term savings and increased production capabilities.

2. Technical Expertise Requirements

Operating advanced automated systems requires a skilled workforce. Companies may need to invest in training for existing employees or hire new staff with the necessary technical expertise.

3. Maintenance and Downtime

Automated systems require regular maintenance to ensure optimal performance. Unexpected breakdowns can lead to production delays, which must be factored into operational planning.

Future Trends in Automated Mousse Production

The future of automated mousse production is bright, with several emerging trends that promise to enhance productivity and efficiency.

1. Integration of AI and Machine Learning

Artificial Intelligence (AI) and machine learning technologies are being integrated into production lines to optimize processes further. These technologies can analyze data from previous batches to predict the best settings for new ones, thereby improving consistency and quality.

2. Real-Time Monitoring and Analytics

Advancements in technology allow for real-time monitoring of production lines. This capability enables manufacturers to make immediate adjustments based on data insights, leading to enhanced quality control and efficiency.

3. Customization and Personalization

As consumer preferences diversify, automated systems will increasingly support customization in mousse production. This capability will allow manufacturers to create unique flavors and textures tailored to individual consumer preferences.

FAQs About Automated Mousse Production Lines

1. What is an automated mousse production line?

An automated mousse production line is a system that uses machinery to handle various stages of mousse production, including ingredient dispensing, mixing, cooling, and packaging, with minimal human intervention.

2. How does automation improve mousse quality?

Automation ensures precise ingredient measurements and consistent mixing processes, leading to uniform texture and taste across all batches of mousse.

3. What are the cost benefits of automated mousse production?

Although initial setup costs are high, automation can lead to significant long-term savings in labor, operational efficiency, and reduced waste.

4. Can automated production lines be customized for different recipes?

Yes, many automated systems are designed to be flexible and can be adjusted to accommodate various mousse recipes and production scales.

5. What are the maintenance requirements for automated systems?

Like any machinery, automated production lines require regular maintenance checks to ensure optimal functionality and prevent unexpected breakdowns.

Conclusion: Embracing the Future of Mousse Production

The benefits of automated mousse production lines are clear. From enhanced efficiency and consistent quality to improved food safety and sustainability, these systems are revolutionizing the food and beverage industry. As technology continues to evolve, manufacturers who embrace automation will be better equipped to meet consumer demands and thrive in an increasingly competitive market. By investing in automated production solutions, companies can ensure they remain at the forefront of the mousse manufacturing sector, delivering delightful products that satisfy every palate.

Mousse Production line

Previous Page