Efficiency and Quality in Muffin Production Lines: A Comprehensive Overview

2026/02/16

---

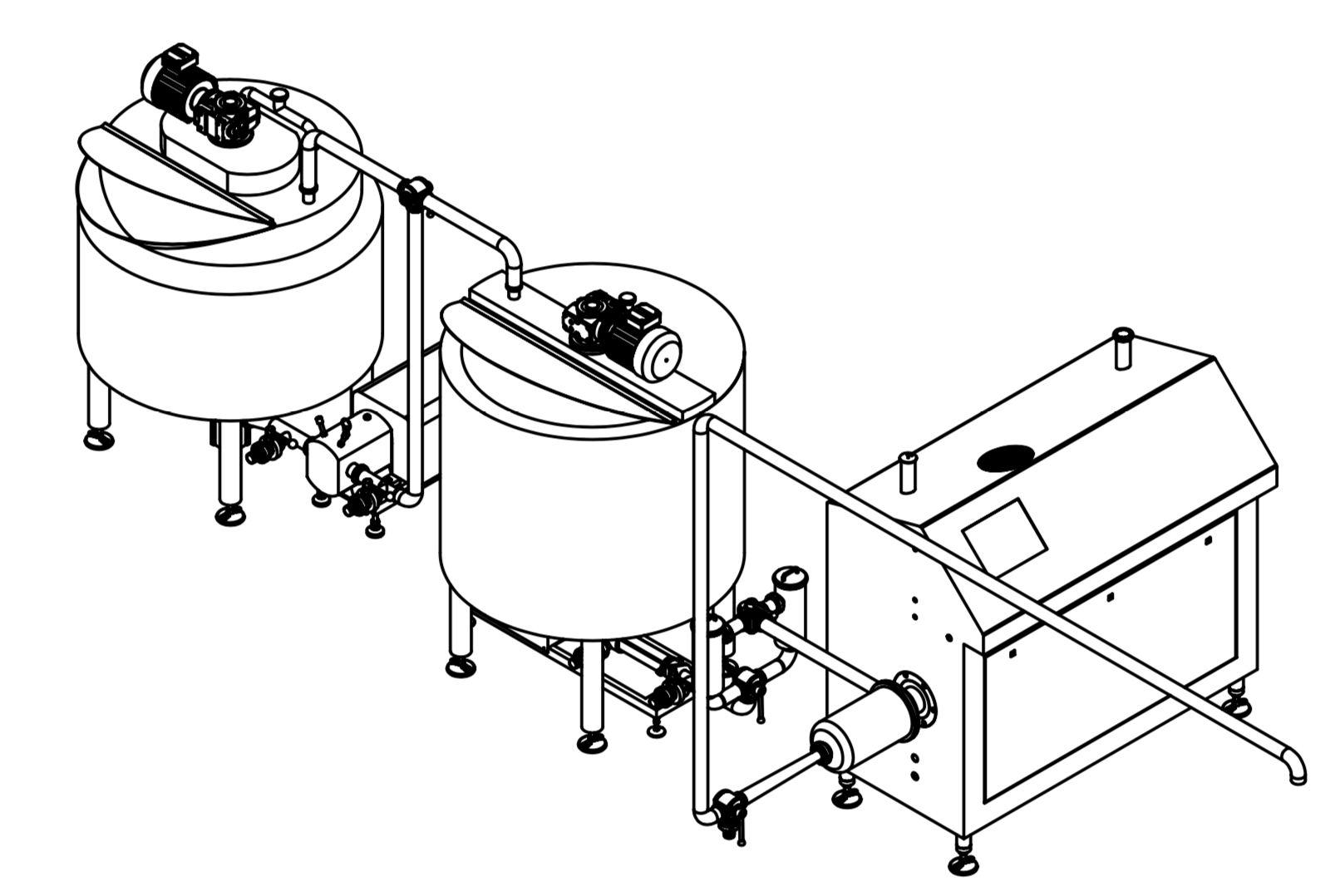

Muffin production lines are specialized setups designed to automate the process of mixing, baking, and packaging muffins. These production lines significantly enhance the efficiency of muffin manufacturing, enabling producers to meet high demand while maintaining quality control. The layout of a typical muffin production line includes several critical components, each serving a specific function to ensure a smooth workflow.

At the beginning of the production line, raw ingredients like flour, sugar, eggs, and flavorings are precisely measured and mixed. Advanced mixing equipment is employed to achieve a consistent batter, which is crucial for uniform baking. Automated systems can adjust mixing times and speeds based on the recipe, ensuring optimal texture and flavor.

Once the batter is prepared, it moves to the filling station, where it is dispensed into muffin trays or molds. This process is typically handled by automated filling machines, which can precisely portion the batter, reducing waste and ensuring each muffin is the same size. Such consistency is vital not only for aesthetic purposes but also for baking performance, as uniform muffins tend to bake more evenly.

The next stage involves baking, where the filled molds are transferred to industrial ovens. Muffin production lines often use conveyor belt systems that allow for continuous baking, maximizing efficiency. These ovens are designed to provide uniform heat distribution, ensuring that muffins rise properly and develop a golden-brown crust. Advanced temperature controls also allow for adjustments based on specific muffin recipes or batch sizes.

After baking, muffins require cooling before they can be packaged. Cooling conveyors are an integral part of the muffin production line, allowing baked goods to cool gradually and preventing condensation that could affect texture and freshness. Once cooled, muffins are ready for packaging, which is typically done using automated packaging machines that wrap or box the muffins for distribution.

In addition to improving efficiency, muffin production lines also enhance quality control. Automated systems can monitor various production parameters, such as ingredient ratios, baking times, and temperatures, ensuring that each batch meets established quality standards. This level of monitoring helps reduce the risk of human error, which can be more prevalent in manual processes.

In conclusion, muffin production lines play a pivotal role in the food processing industry by offering efficiency, consistency, and improved quality control. Manufacturers looking to optimize their production processes will find that investing in advanced muffin production lines can lead to significant gains in productivity and product consistency, ultimately leading to greater customer satisfaction. Understanding the components and benefits of these production lines can help businesses make informed decisions about their manufacturing strategies.

Muffin production lines are specialized setups designed to automate the process of mixing, baking, and packaging muffins. These production lines significantly enhance the efficiency of muffin manufacturing, enabling producers to meet high demand while maintaining quality control. The layout of a typical muffin production line includes several critical components, each serving a specific function to ensure a smooth workflow.

At the beginning of the production line, raw ingredients like flour, sugar, eggs, and flavorings are precisely measured and mixed. Advanced mixing equipment is employed to achieve a consistent batter, which is crucial for uniform baking. Automated systems can adjust mixing times and speeds based on the recipe, ensuring optimal texture and flavor.

Once the batter is prepared, it moves to the filling station, where it is dispensed into muffin trays or molds. This process is typically handled by automated filling machines, which can precisely portion the batter, reducing waste and ensuring each muffin is the same size. Such consistency is vital not only for aesthetic purposes but also for baking performance, as uniform muffins tend to bake more evenly.

The next stage involves baking, where the filled molds are transferred to industrial ovens. Muffin production lines often use conveyor belt systems that allow for continuous baking, maximizing efficiency. These ovens are designed to provide uniform heat distribution, ensuring that muffins rise properly and develop a golden-brown crust. Advanced temperature controls also allow for adjustments based on specific muffin recipes or batch sizes.

After baking, muffins require cooling before they can be packaged. Cooling conveyors are an integral part of the muffin production line, allowing baked goods to cool gradually and preventing condensation that could affect texture and freshness. Once cooled, muffins are ready for packaging, which is typically done using automated packaging machines that wrap or box the muffins for distribution.

In addition to improving efficiency, muffin production lines also enhance quality control. Automated systems can monitor various production parameters, such as ingredient ratios, baking times, and temperatures, ensuring that each batch meets established quality standards. This level of monitoring helps reduce the risk of human error, which can be more prevalent in manual processes.

In conclusion, muffin production lines play a pivotal role in the food processing industry by offering efficiency, consistency, and improved quality control. Manufacturers looking to optimize their production processes will find that investing in advanced muffin production lines can lead to significant gains in productivity and product consistency, ultimately leading to greater customer satisfaction. Understanding the components and benefits of these production lines can help businesses make informed decisions about their manufacturing strategies.

Muffin Production line

Previous Page