Behind the Scenes: How a Layer Cake Production Line Works

2026/02/13

Behind the Scenes: How a Layer Cake Production Line Works

Introduction to Layer Cake Production

Producing layer cakes on a commercial scale involves a series of meticulously coordinated processes. Understanding these steps not only highlights the complexity of industrial baking but also showcases the technology and machinery that ensure the quality and consistency of these beloved desserts.

The Importance of Automation in Cake Production

Automation plays a crucial role in modern layer cake production lines. It enhances efficiency, reduces human error, and ensures that each cake meets the rigorous standards of quality that consumers expect. From mixing ingredients to baking and decorating, automation streamlines processes that would otherwise be time-consuming and labor-intensive.

Key Benefits of Automated Production Lines

- **Consistency**: Each cake produced is uniform in size, flavor, and texture, which is essential for brand recognition.

- **Speed**: Automated processes significantly increase production rates, allowing businesses to meet high demand.

- **Precision**: Accurate measurements and timing lead to better quality control, minimizing waste and maximizing profits.

- **Labor Savings**: Automation reduces the need for manual labor in repetitive tasks, allowing staff to focus on quality assurance and creative aspects of cake design.

Ingredients: The Building Blocks of a Delicious Layer Cake

The foundation of any layer cake begins with high-quality ingredients. The selection of ingredients affects not only flavor but also texture and appearance.

Essential Ingredients Used in Layer Cake Production

- **Flour**: The primary component for structure. Cake flour is often used for its fine texture.

- **Sugar**: Both white and brown sugars contribute to sweetness and moisture.

- **Eggs**: They provide richness and help bind the ingredients together.

- **Butter**: Adds flavor and moisture, contributing to a tender crumb.

- **Leavening Agents**: Baking powder and baking soda ensure the cake rises to the perfect height.

- **Flavorings and Fillings**: Vanilla extract, cocoa powder, fruits, and creams enhance the overall taste profile.

The Layer Cake Production Process Step by Step

Understanding the production line process is key to appreciating the efficiency and precision involved in creating layer cakes.

1. Ingredient Preparation

The process begins with the careful measuring and preparation of ingredients. This step often utilizes automated weighing systems to ensure precision.

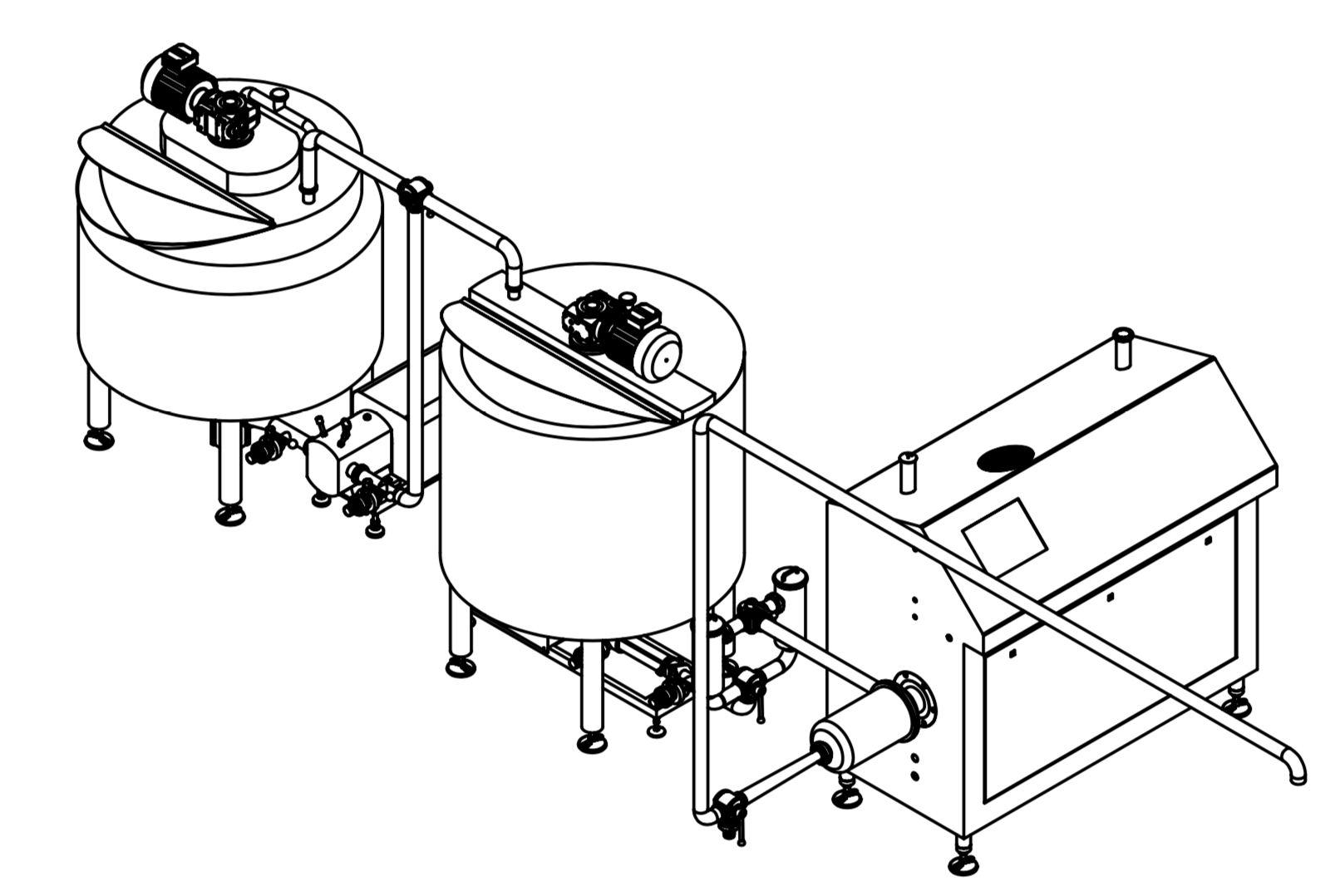

2. Mixing the Batter

Once the ingredients are prepared, they are combined in large mixers. This stage is crucial; an effective mixing process ensures that all components are evenly distributed, leading to a uniform batter.

3. Baking the Layers

The batter is poured into preheated cake pans and placed in industrial ovens. These ovens are designed for consistency, providing even heat distribution essential for the perfect bake.

4. Cooling and Handling

After baking, the layers must cool before they can be handled. Automated cooling racks may be used to expedite this process, ensuring efficiency in the workflow.

5. Layer Assembly

Once cooled, the cake layers are stacked with fillings in between. This step can involve automated layer handling systems that place cakes precisely and uniformly.

6. Frosting and Decoration

Frosting machines apply a smooth layer of icing, while decorators may add intricate designs. This process combines both technology and artistry, ensuring each cake is visually appealing.

7. Quality Control and Packaging

Final inspections are critical. Automated systems check for size, weight, and appearance. Once approved, the cakes are packaged for shipping, often using machinery that optimally seals and labels each box.

Innovations in Layer Cake Production Technology

The food manufacturing industry is continually evolving, and layer cake production is no exception. Innovative technologies are implemented to improve efficiency and product quality.

Advanced Mixing Technologies

New mixing technologies allow for better aeration of batters, enhancing the cake's texture and overall quality.

Smart Ovens

Modern ovens equipped with sensors help maintain optimal baking conditions, adjusting temperature and humidity as needed for perfect results.

Robotic Handling Systems

Robotics enhance the efficiency of layer assembly and decoration, allowing for precision that manual processes cannot match.

Sustainability in Cake Production

Sustainability has become a focal point in the manufacturing sector, including cake production. Businesses now aim to minimize their environmental impact through various practices.

Eco-Friendly Packaging Solutions

Many manufacturers are transitioning to biodegradable or recyclable packaging materials to reduce waste.

Energy-Efficient Machinery

Investing in energy-efficient machines not only lowers operational costs but also reduces the carbon footprint of production.

Waste Reduction Strategies

Implementing strategies to minimize waste—such as reusing excess batter or using by-products—has become a priority for many manufacturers.

The Future of Layer Cake Production

As consumer preferences evolve, so too does the layer cake production process. Trends such as gluten-free, vegan, and organic cakes are gaining traction. Future advancements may focus on enhancing customization options, allowing consumers to have cakes tailored to their specific desires.

Personalization Trends in Baking

Consumers increasingly seek personalized cakes for special occasions. Production lines may need to adapt to incorporate more variety without sacrificing efficiency.

Health-Conscious Innovations

With a growing trend towards healthier eating, the industry is exploring alternative ingredients that offer lower sugar and fat options without compromising taste.

Frequently Asked Questions (FAQs)

1. What is the average production speed of a layer cake line?

The speed varies greatly depending on the machinery and scale, but a high-output line can produce hundreds of cakes per hour.

2. How do manufacturers ensure quality control in layer cakes?

Quality control is maintained through regular inspections and automated systems that monitor baking conditions and final product specifications.

3. Are all layer cakes produced using the same process?

While the fundamental steps remain similar, variations exist based on the type of cake, production scale, and specific recipes.

4. What role does technology play in modern cake production?

Technology enhances efficiency, consistency, and quality through automation, advanced machinery, and innovative production methods.

5. How are sustainability practices integrated into cake production?

Manufacturers adopt eco-friendly packaging, energy-efficient machinery, and waste reduction strategies to promote sustainability.

Conclusion

The production of layer cakes on an industrial scale is a fascinating blend of technology, artistry, and efficiency. By understanding the steps and innovations involved, we appreciate not only the delicious end product but also the intricate processes that bring it to life. As the industry continues to evolve, the future of layer cake production promises exciting possibilities that cater to an increasingly diverse consumer base. Embracing technology and sustainability will not only enhance production capabilities but also align with the values of modern consumers, ensuring that layer cakes remain a beloved treat for generations to come.

Layer Cake Production line