How to Optimize Your Candy Production Line with a Marshmallow Aeration Machine

2025/12/06

How to Optimize Your Candy Production Line with a Marshmallow Aeration Machine

The Importance of Aeration in Candy Production

Aeration plays a crucial role in the manufacturing of candy, specifically marshmallows and other aerated confections. The process introduces air into the mixture, resulting in a light and fluffy texture that customers love. However, the traditional methods can be inefficient and inconsistent. This is where the **marshmallow aeration machine** comes into play, revolutionizing the way candy is produced.

Understanding Marshmallow Aeration Machines

Marshmallow aeration machines are specialized equipment designed to incorporate air into candy mixtures effectively. These machines ensure uniform aeration, resulting in consistent product quality. They utilize a variety of mechanisms, such as:

- Mechanical Whipping: Utilizing high-speed blades to whip air into the mixture.

- Vacuum Technology: Creating a vacuum environment to produce bubbles in low-density mixes.

- Temperature Control: Maintaining optimal temperatures during the aeration process for the best results.

Benefits of Using a Marshmallow Aeration Machine

Incorporating a marshmallow aeration machine into your production line comes with numerous benefits:

1. Enhanced Product Quality

The uniform aeration achieved by these machines results in a consistent texture, ensuring customers enjoy the same great taste every time.

2. Increased Production Efficiency

These machines operate at higher speeds than traditional methods, allowing manufacturers to produce larger batches of candy in less time.

3. Cost Savings

By optimizing the aeration process, manufacturers can reduce ingredient waste and energy consumption, leading to significant cost savings.

4. Flexibility in Production

Many marshmallow aeration machines offer adjustable settings, allowing manufacturers to experiment with different formulations and flavors.

How to Select the Right Marshmallow Aeration Machine

Choosing the right marshmallow aeration machine is crucial in optimizing your candy production line. Here are key factors to consider:

1. Capacity Needs

Evaluate your production volume to determine the capacity required. Machines come in various sizes, so choosing one that meets your needs without unnecessary excess is vital.

2. Aeration Technology

Different machines utilize various aeration methods. Research and select one that aligns with your production goals and product requirements.

3. Ease of Cleaning and Maintenance

A machine that is easy to clean and maintain will minimize downtime and keep your production line running smoothly.

4. Supplier Reputation

Consider the reputation of the manufacturer. A reputable supplier will offer robust support, warranty options, and high-quality equipment.

Integrating a Marshmallow Aeration Machine into Your Production Line

Once the right machine is selected, the integration process is next. Here's how to do it effectively:

1. Prepare Your Production Environment

Ensure your production area is equipped with the necessary utilities such as power supply, water, and adequate ventilation.

2. Train Your Staff

Provide thorough training for your production team on operating the marshmallow aeration machine. This step is crucial for safety and efficiency.

3. Conduct Test Runs

Before full-scale production, conduct several test runs to fine-tune the machine settings and ensure optimal performance.

4. Monitor Production Metrics

Analyze production metrics such as output volume, texture consistency, and quality to ensure that the new aeration process meets your standards.

Common Challenges and Solutions in Candy Production

While optimizing your candy production line, you may encounter challenges. Below are common issues and practical solutions:

1. Inconsistent Texture

**Solution:** Regularly calibrate the aeration machine and conduct texture tests during production runs to maintain consistency.

2. Ingredient Separation

**Solution:** Ensure proper mixing before and after aeration. Implement a thorough mixing process to prevent ingredient separation.

3. Equipment Downtime

**Solution:** Schedule regular maintenance and have a backup plan, including secondary equipment, to minimize disruptions.

Maximizing the Efficiency of Your Production Line

To further enhance your production line’s efficiency, consider these additional strategies:

1. Use High-Quality Ingredients

Investing in high-quality ingredients can improve the end product’s taste and texture, reducing waste and enhancing customer satisfaction.

2. Streamline Workflow Processes

Analyze your workflow and identify bottlenecks. Streamlining processes can significantly boost overall productivity.

3. Invest in Automation

Incorporate automation into your production line wherever possible. Automated systems can increase precision and reduce labor costs.

Future Trends in Candy Production

As technology advances, the candy production industry continues to evolve. Here are some trends to watch:

1. Sustainable Practices

Consumers are increasingly seeking eco-friendly products. Implementing sustainable practices in sourcing ingredients and packaging can enhance brand appeal.

2. Health-Conscious Innovations

The demand for healthier candy options is on the rise. Experimenting with organic ingredients and reducing sugar levels can attract a broader customer base.

3. Smart Manufacturing Solutions

The integration of IoT (Internet of Things) in manufacturing allows for real-time monitoring and adjustments, leading to increased efficiency and reduced waste.

Frequently Asked Questions (FAQs)

1. What is a marshmallow aeration machine?

A marshmallow aeration machine is specialized equipment designed to incorporate air into the candy mixture, producing a light and fluffy texture.

2. How does aeration affect candy texture?

Aeration introduces air bubbles, creating a lighter texture that enhances the mouthfeel and overall quality of the candy.

3. Can I adjust the settings on a marshmallow aeration machine?

Most machines come with adjustable settings, allowing you to customize the aeration process based on your specific product requirements.

4. What are the maintenance requirements for these machines?

Regular cleaning and maintenance are essential for optimal performance. Follow the manufacturer’s guidelines for best practices.

5. How can I troubleshoot inconsistent candy texture?

Ensure proper calibration of the aeration machine, conduct regular quality tests, and review your mixing processes to address inconsistencies.

Conclusion

Optimizing your candy production line with a marshmallow aeration machine is a strategic move that can enhance product quality, increase efficiency, and reduce costs. By understanding the technology, selecting the right equipment, and integrating it effectively into your production process, you can significantly improve your operations. As the candy industry continues to evolve, staying ahead through innovation and quality will ensure your products stand out in a competitive market. Embrace the benefits of aeration technology and watch your candy production soar to new heights.

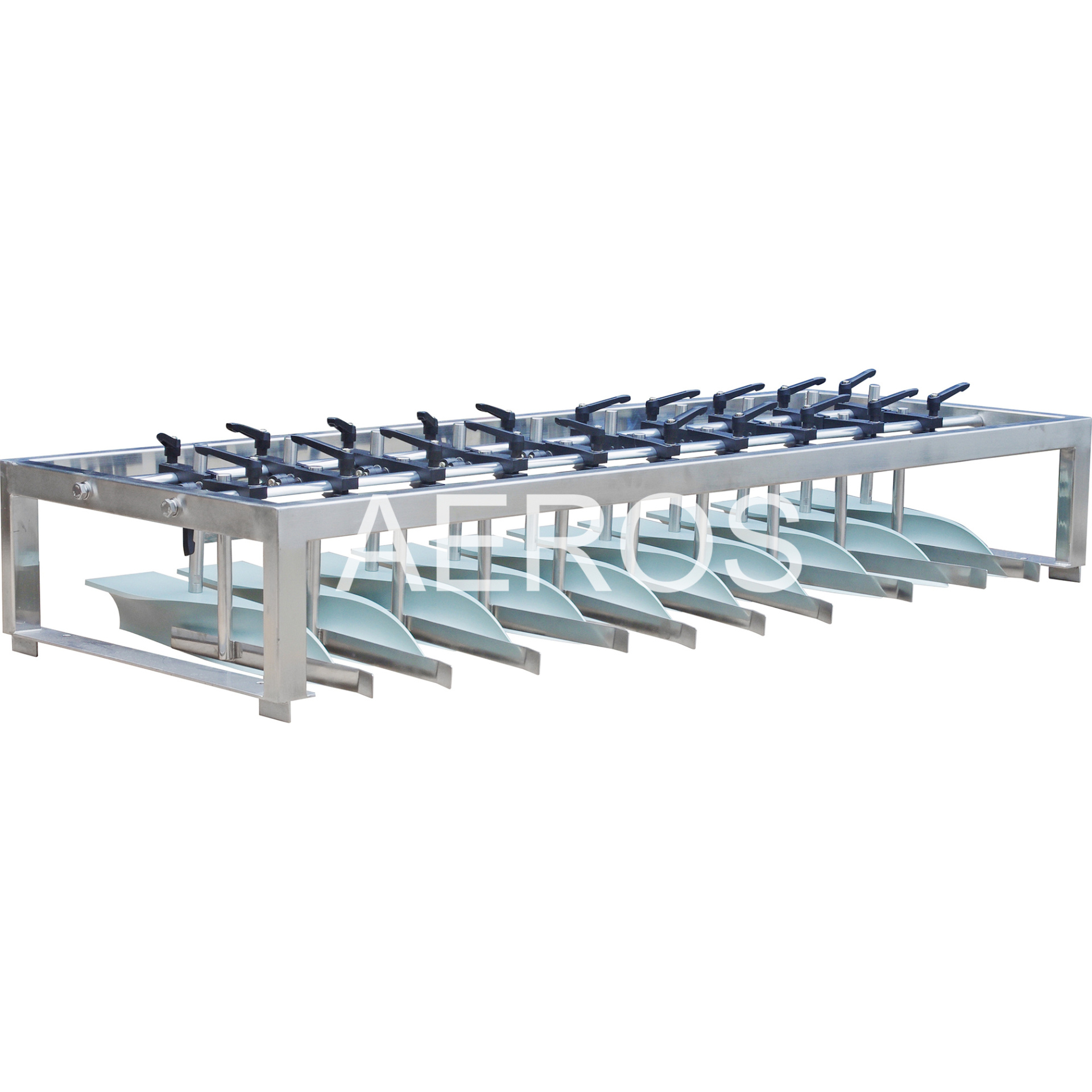

Marshmallow aeration machine