Understanding the Cake Continuous Aeration System: Enhancing Food Processing Efficiency

2025/12/09

In the realm of food processing, particularly in the production of cakes and other baked goods, the quality of the final product greatly depends on the aeration process. The Cake Continuous Aeration System stands out as a vital technology designed to enhance the aeration of cake batters, ensuring a consistent and high-quality product.

Aeration is the process of incorporating air into a mixture, which is crucial for achieving the desired texture and volume in cake products. Traditional methods often involve manual mixing or batch processes that can lead to inconsistent results. The Cake Continuous Aeration System addresses these limitations by providing a continuous and controlled aeration process.

One of the primary benefits of this system is its ability to maintain uniformity in aeration. By continuously introducing air into the batter, the system ensures that the mixture achieves the optimal density and consistency required for baking. This not only enhances the cake’s texture but also improves its volume, making it more appealing to consumers.

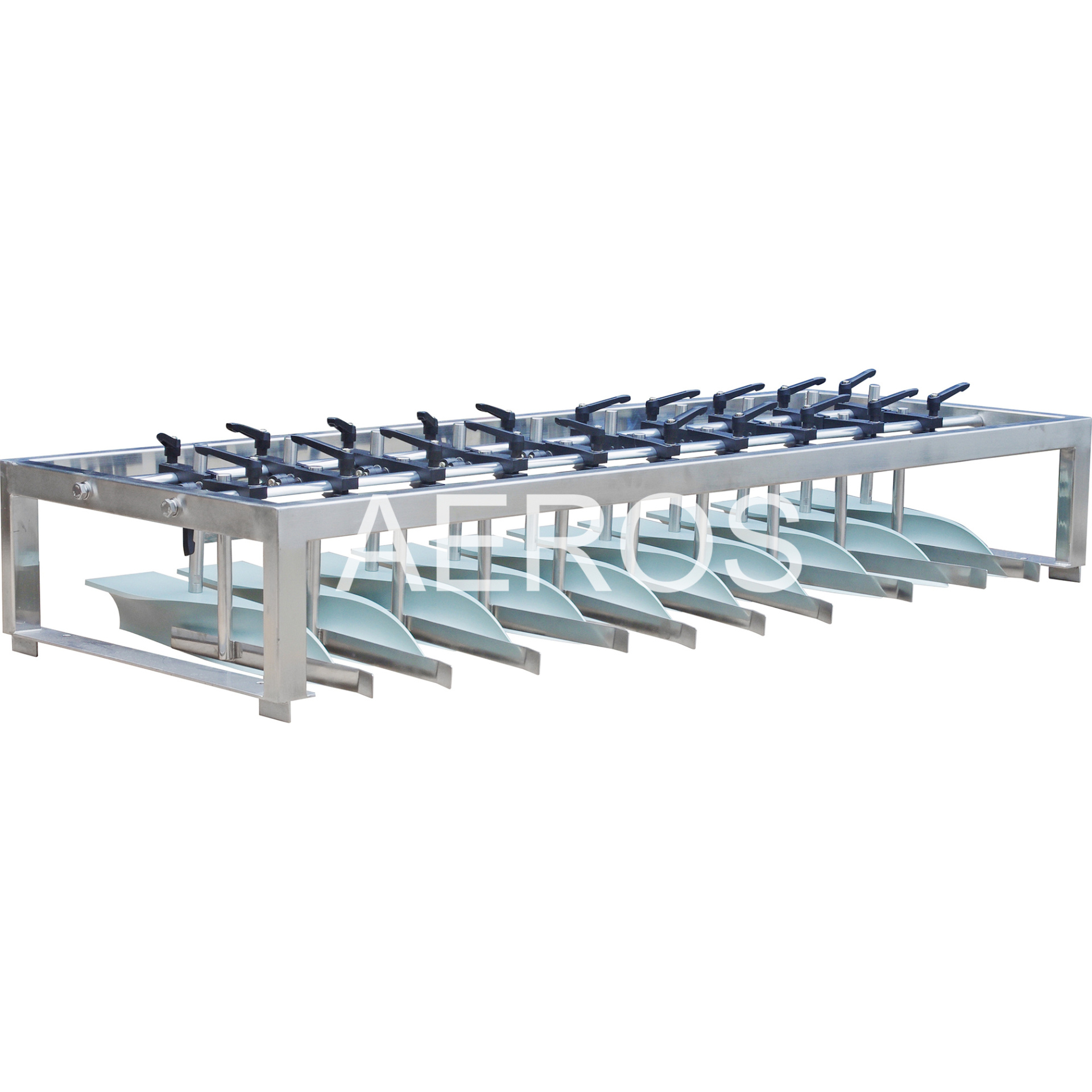

The design of the Cake Continuous Aeration System is typically characterized by its efficient mixing chambers and aeration nozzles. These components work in tandem to ensure that air is evenly distributed throughout the batter. This uniform distribution is critical, as it minimizes the risk of over-aeration or under-aeration, both of which can adversely affect the final product.

Moreover, the Cake Continuous Aeration System is engineered for energy efficiency. By automating the aeration process, it reduces the need for manual labor and minimizes the time spent on preparing the batter. This not only streamlines production but also allows manufacturers to meet high demand without compromising quality.

In addition to improving the texture and volume of cakes, the Cake Continuous Aeration System contributes to other aspects of food safety and hygiene. The system is designed to minimize contamination risks, ensuring that the aeration process adheres to strict food safety standards. This is particularly important in the food and beverage processing industry, where hygiene and quality control are paramount.

Furthermore, implementing this system can lead to cost savings in the long run. By increasing production efficiency and reducing waste associated with inconsistent batches, manufacturers can optimize their resource use and enhance profitability.

In conclusion, the Cake Continuous Aeration System is a transformative technology in the food processing industry, particularly for cake production. Its ability to provide consistent aeration, improve product quality, and promote efficiency makes it an invaluable asset for manufacturers aiming to excel in the competitive food market. As the industry evolves, embracing such innovative solutions will be crucial for achieving success and maintaining high standards in food quality and safety.

Aeration is the process of incorporating air into a mixture, which is crucial for achieving the desired texture and volume in cake products. Traditional methods often involve manual mixing or batch processes that can lead to inconsistent results. The Cake Continuous Aeration System addresses these limitations by providing a continuous and controlled aeration process.

One of the primary benefits of this system is its ability to maintain uniformity in aeration. By continuously introducing air into the batter, the system ensures that the mixture achieves the optimal density and consistency required for baking. This not only enhances the cake’s texture but also improves its volume, making it more appealing to consumers.

The design of the Cake Continuous Aeration System is typically characterized by its efficient mixing chambers and aeration nozzles. These components work in tandem to ensure that air is evenly distributed throughout the batter. This uniform distribution is critical, as it minimizes the risk of over-aeration or under-aeration, both of which can adversely affect the final product.

Moreover, the Cake Continuous Aeration System is engineered for energy efficiency. By automating the aeration process, it reduces the need for manual labor and minimizes the time spent on preparing the batter. This not only streamlines production but also allows manufacturers to meet high demand without compromising quality.

In addition to improving the texture and volume of cakes, the Cake Continuous Aeration System contributes to other aspects of food safety and hygiene. The system is designed to minimize contamination risks, ensuring that the aeration process adheres to strict food safety standards. This is particularly important in the food and beverage processing industry, where hygiene and quality control are paramount.

Furthermore, implementing this system can lead to cost savings in the long run. By increasing production efficiency and reducing waste associated with inconsistent batches, manufacturers can optimize their resource use and enhance profitability.

In conclusion, the Cake Continuous Aeration System is a transformative technology in the food processing industry, particularly for cake production. Its ability to provide consistent aeration, improve product quality, and promote efficiency makes it an invaluable asset for manufacturers aiming to excel in the competitive food market. As the industry evolves, embracing such innovative solutions will be crucial for achieving success and maintaining high standards in food quality and safety.

Cake continuous aeration system