The Growing Demand for Continuous Aeration Machines in the Manufacturing Sector

2025/09/16

The Growing Demand for Continuous Aeration Machines in the Manufacturing Sector

Table of Contents

- 1. Introduction

- 2. Understanding Continuous Aeration Machines

- 3. Applications of Continuous Aeration Machines in Manufacturing

- 4. Benefits of Continuous Aeration Machines

- 5. Technological Advancements in Aeration Technology

- 6. Challenges Facing Continuous Aeration Machines

- 7. Future Trends in Continuous Aeration

- 8. Case Studies: Success Stories in Continuous Aeration

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction

The manufacturing sector is undergoing a significant transformation, primarily driven by the need for enhanced efficiency and productivity. One of the key players in this evolution is the **continuous aeration machine**, a vital component in various manufacturing processes. As industries aim to improve product quality while reducing operational costs, the demand for continuous aeration machines has surged. This article explores the growing demand for these machines, highlighting their applications, benefits, and future trends within the manufacturing landscape.

2. Understanding Continuous Aeration Machines

Continuous aeration machines are designed to facilitate the introduction of air into liquids or slurries in a controlled manner. This process is essential for a variety of manufacturing applications, including wastewater treatment, chemical processing, and food and beverage production. Unlike traditional aeration systems, continuous aeration machines operate seamlessly, providing constant oxygenation to ensure optimum conditions for chemical reactions and biological processes.

The Mechanism of Continuous Aeration

These machines utilize advanced technologies to inject air or oxygen through diffusers, ensuring uniform distribution. The aeration process not only accelerates reactions but also enhances the quality of the end products. Continuous aeration machines are equipped with sensors and monitoring systems that allow for real-time adjustments, maximizing efficiency and reducing energy consumption.

3. Applications of Continuous Aeration Machines in Manufacturing

Continuous aeration machines find applications across various sectors, transforming how manufacturing processes operate. Below are some key applications:

3.1 Wastewater Treatment

In wastewater treatment facilities, continuous aeration machines play a crucial role in promoting aerobic digestion, where microorganisms break down organic materials. This process enhances the treatment efficiency, leading to cleaner effluent discharge and compliance with environmental regulations.

3.2 Chemical Processing

In chemical manufacturing, continuous aeration is vital for processes such as oxidation and fermentation. By maintaining optimal dissolved oxygen levels, manufacturers can achieve desired reaction rates and produce high-quality products.

3.3 Food and Beverage Production

The food industry benefits significantly from continuous aeration, especially in fermentation processes for beverages like beer and wine. Controlled aeration ensures consistent flavor profiles and product quality, which are critical to consumer satisfaction.

4. Benefits of Continuous Aeration Machines

The increasing adoption of continuous aeration machines in manufacturing is driven by numerous benefits:

4.1 Enhanced Efficiency

Continuous aeration machines streamline processes by providing consistent oxygenation, leading to faster reaction times and improved throughput.

4.2 Cost Savings

By optimizing oxygen use and minimizing energy consumption, manufacturers can significantly reduce operational costs. Continuous aeration machines often result in lower energy bills and reduced maintenance costs compared to traditional systems.

4.3 Improved Product Quality

Consistent aeration leads to uniform product quality, which is paramount for maintaining brand reputation and consumer trust.

4.4 Environmental Compliance

With stricter environmental regulations, the use of continuous aeration machines helps manufacturers meet compliance standards by improving effluent quality in wastewater treatment processes.

5. Technological Advancements in Aeration Technology

The field of aeration technology is rapidly evolving, with continuous improvements enhancing the performance and efficiency of these machines.

5.1 Smart Aeration Systems

Recent advancements include smart aeration systems equipped with IoT technology, enabling remote monitoring and control. These systems allow manufacturers to optimize aeration rates based on real-time data, leading to even greater efficiency.

5.2 Energy-Efficient Designs

Innovations in design, such as low-energy diffusers and advanced motor technologies, have resulted in machines that require less power while maintaining high performance levels.

5.3 Advanced Materials

The use of durable, corrosion-resistant materials in the construction of continuous aeration machines enhances their longevity and reduces maintenance needs.

6. Challenges Facing Continuous Aeration Machines

Despite their numerous benefits, continuous aeration machines face specific challenges that manufacturers must address:

6.1 Initial Investment Costs

The upfront cost of implementing continuous aeration technology can be significant. However, manufacturers often find that the long-term savings and efficiency gains justify the initial investment.

6.2 Technical Expertise

Incorporating advanced aeration systems may require specialized technical knowledge. Manufacturers may need to invest in training for staff to ensure proper operation and maintenance.

6.3 Integration with Existing Systems

Integrating new continuous aeration machines into existing manufacturing processes can present challenges. Careful planning and consultation with experts can mitigate potential issues during implementation.

7. Future Trends in Continuous Aeration

As the manufacturing sector continues to evolve, several trends are shaping the future of continuous aeration machines:

7.1 Increased Automation

The trend towards automation in manufacturing will likely drive the development of more sophisticated continuous aeration systems that can operate autonomously, further improving efficiency.

7.2 Sustainability Focus

With a growing emphasis on sustainability, manufacturers are seeking solutions that reduce energy consumption and environmental impact. Continuous aeration machines that utilize renewable energy sources may become more prevalent.

7.3 Customization and Flexibility

Future continuous aeration solutions will likely emphasize customization, allowing manufacturers to tailor systems to their specific needs and processes for optimal performance.

8. Case Studies: Success Stories in Continuous Aeration

To illustrate the effectiveness of continuous aeration machines, we can look at several case studies from various sectors:

8.1 Wastewater Treatment Facility

A major wastewater treatment facility implemented continuous aeration technology and reported a 30% increase in treatment efficiency, significantly reducing operational costs and improving compliance with environmental regulations.

8.2 Beverage Manufacturer

A beverage manufacturer adopted continuous aeration for its fermentation process, resulting in a 20% reduction in production time and consistent quality across batches, enhancing overall product reputation in the market.

9. Conclusion

The **growing demand for continuous aeration machines** in the manufacturing sector reflects a broader trend towards efficiency, quality, and sustainability. As manufacturers increasingly recognize the benefits of these advanced systems, they are poised to transform various industries, from wastewater treatment to food and beverage production. The future of continuous aeration machines looks promising, with ongoing technological advancements and a focus on customization driving further growth. Embracing this technology not only optimizes manufacturing processes but also positions businesses for success in an ever-competitive market.

10. Frequently Asked Questions

10.1 What is a continuous aeration machine?

A continuous aeration machine is a device used to introduce air or oxygen into liquids or slurries in a controlled manner, facilitating various processes in manufacturing, such as fermentation and wastewater treatment.

10.2 How does continuous aeration improve manufacturing processes?

Continuous aeration enhances manufacturing processes by providing consistent oxygenation, leading to faster reaction times, improved product quality, and reduced operational costs.

10.3 What industries benefit from continuous aeration technology?

Industries such as wastewater treatment, food and beverage production, and chemical processing benefit significantly from continuous aeration technology.

10.4 What are the challenges of implementing continuous aeration machines?

Challenges include initial investment costs, the need for technical expertise, and integration with existing systems.

10.5 What future trends are expected in continuous aeration technology?

Future trends include increased automation, a focus on sustainability, and greater customization options for specific manufacturing needs.

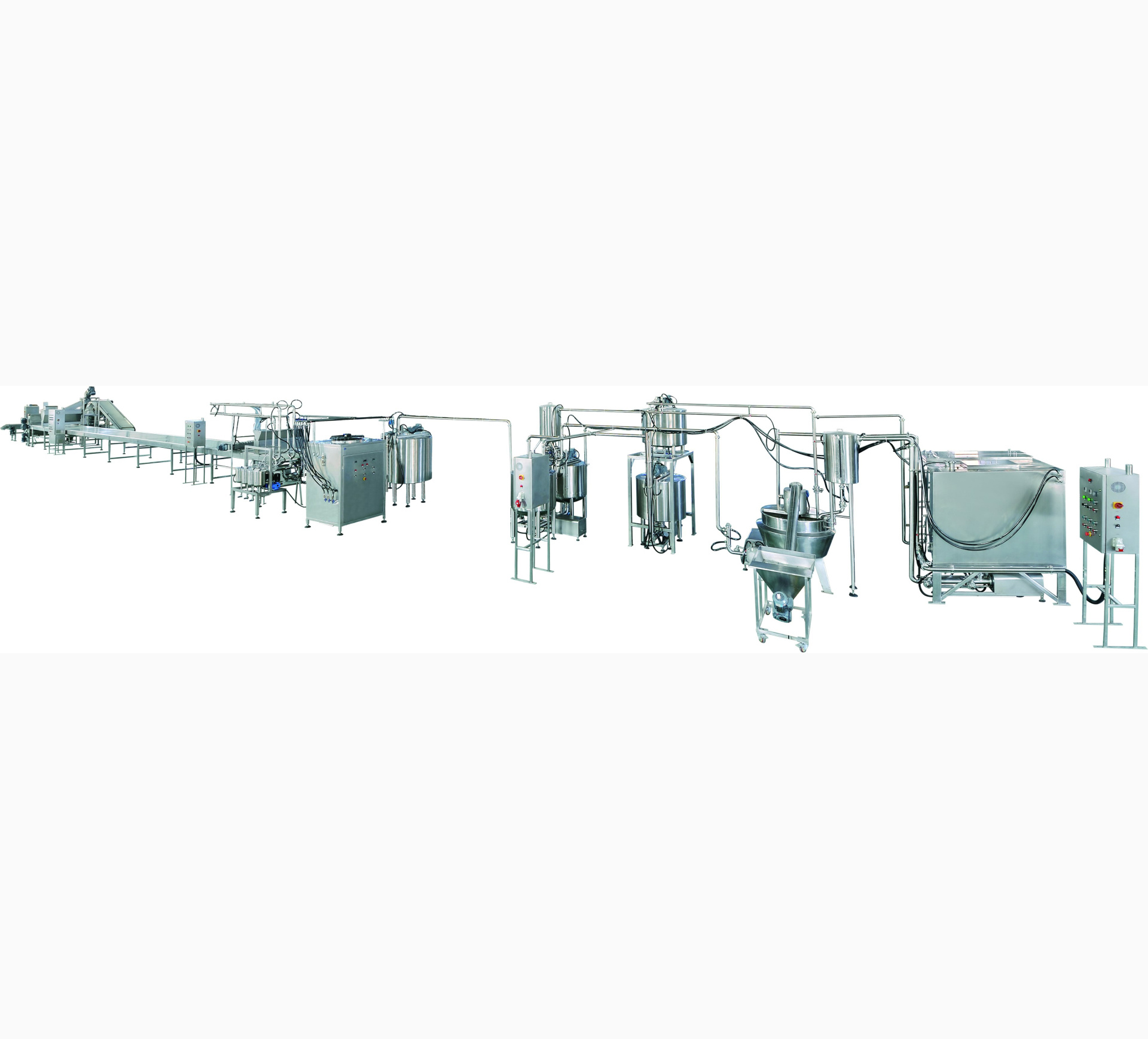

Continuous aeration machine from china