The Revolution of New Aerated Chocolate Production Lines: A Game Changer in Food Processing

2025/07/25

In the competitive landscape of the food processing industry, innovation is key to meeting consumer demand and staying ahead of market trends. One such innovation is the introduction of new aerated chocolate production lines. These advanced systems are designed to create aerated chocolate products, which have gained popularity due to their unique texture and taste profile. Understanding the technology and benefits of these production lines can provide manufacturers with a significant advantage.

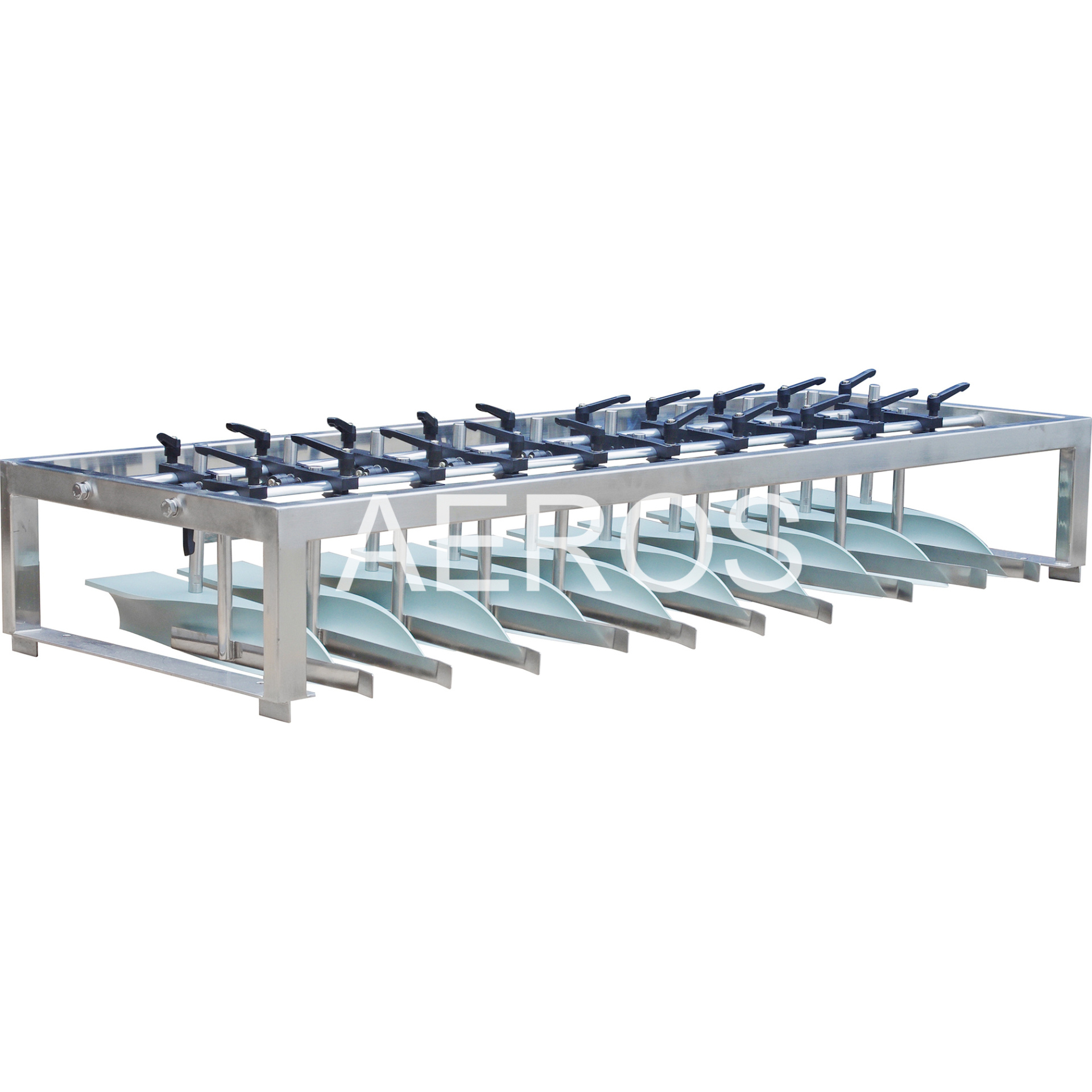

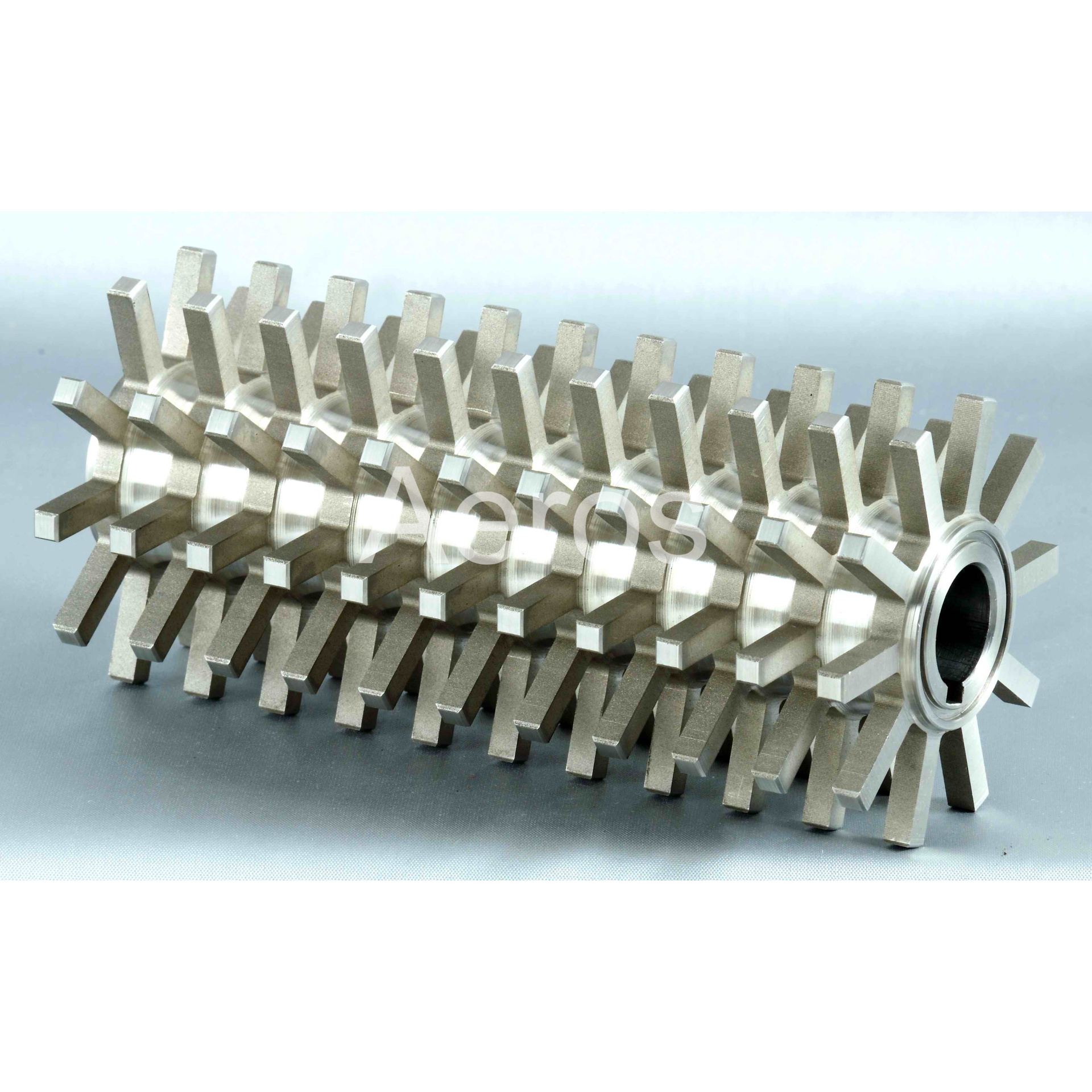

Aerated chocolate is distinguished by its light, fluffy texture, which is achieved through the incorporation of air during the chocolate-making process. The new aerated chocolate production lines utilize cutting-edge equipment that allows for precise control over the aeration process. This involves the use of specialized mixers and pumps that blend cocoa mass, sugar, and other ingredients while introducing air bubbles. The result is a product that is not only visually appealing but also has a delightful mouthfeel that consumers love.

One of the most significant advantages of implementing new aerated chocolate production lines is the efficiency they bring to the manufacturing process. Traditional chocolate production can be time-consuming and labor-intensive, often requiring multiple stages to achieve the desired texture. In contrast, these modern production lines streamline the process, reducing production time and labor costs. Additionally, they can be easily integrated into existing manufacturing setups, allowing for a smooth transition to more advanced technology.

Quality control is another critical aspect of food processing, and new aerated chocolate production lines are equipped with sophisticated monitoring systems. These systems ensure that the aeration process is consistent, resulting in a uniform product that meets quality standards. Manufacturers can achieve higher consistency in flavor and texture, which is essential for building brand loyalty and meeting consumer expectations.

Moreover, the introduction of aerated chocolate products opens up new market opportunities. Consumers are increasingly seeking novelty and variety in their chocolate options, and aerated chocolate fits the bill. By leveraging the capabilities of new aerated chocolate production lines, manufacturers can develop innovative products that cater to changing consumer preferences, such as low-calorie or organic variants.

In conclusion, the new aerated chocolate production line represents a significant advancement in the food processing industry, offering manufacturers enhanced efficiency, quality control, and the potential for product innovation. As consumer demands evolve, embracing such technologies will be crucial for staying competitive and meeting the needs of the modern market. Investing in these production lines not only helps in producing superior products but also paves the way for future growth in the dynamic world of food manufacturing.

Aerated chocolate is distinguished by its light, fluffy texture, which is achieved through the incorporation of air during the chocolate-making process. The new aerated chocolate production lines utilize cutting-edge equipment that allows for precise control over the aeration process. This involves the use of specialized mixers and pumps that blend cocoa mass, sugar, and other ingredients while introducing air bubbles. The result is a product that is not only visually appealing but also has a delightful mouthfeel that consumers love.

One of the most significant advantages of implementing new aerated chocolate production lines is the efficiency they bring to the manufacturing process. Traditional chocolate production can be time-consuming and labor-intensive, often requiring multiple stages to achieve the desired texture. In contrast, these modern production lines streamline the process, reducing production time and labor costs. Additionally, they can be easily integrated into existing manufacturing setups, allowing for a smooth transition to more advanced technology.

Quality control is another critical aspect of food processing, and new aerated chocolate production lines are equipped with sophisticated monitoring systems. These systems ensure that the aeration process is consistent, resulting in a uniform product that meets quality standards. Manufacturers can achieve higher consistency in flavor and texture, which is essential for building brand loyalty and meeting consumer expectations.

Moreover, the introduction of aerated chocolate products opens up new market opportunities. Consumers are increasingly seeking novelty and variety in their chocolate options, and aerated chocolate fits the bill. By leveraging the capabilities of new aerated chocolate production lines, manufacturers can develop innovative products that cater to changing consumer preferences, such as low-calorie or organic variants.

In conclusion, the new aerated chocolate production line represents a significant advancement in the food processing industry, offering manufacturers enhanced efficiency, quality control, and the potential for product innovation. As consumer demands evolve, embracing such technologies will be crucial for staying competitive and meeting the needs of the modern market. Investing in these production lines not only helps in producing superior products but also paves the way for future growth in the dynamic world of food manufacturing.

new Aerated chocolate production line