-

About

AboutAeros is the main supplier for continuous aeration system in China.With the technical know-how, experience & resources to meet individual customer requirement, whether this is for a single unit or a complete turn key project.

-

Equipment

EquipmentYalus has strong mechanical development strength and excellent processing technology

-

Application

ApplicationQuality and service are the core competencies of Aeros, and all our services are designed to achieve a common goal: to maintain stable production and maintain a high level of productivity of the equipment during the service cycle.

-

Training & Services

Training & ServicesQuality and service are the core competencies of Aeros, and all our services are designed to achieve a common goal: to maintain stable production and maintain a high level of productivity of the equipment during the service cycle.

-

Contact

ContactQuality and service are the core competencies of Aeros, and all our services are designed to achieve a common goal: to maintain stable production and maintain a high level of productivity of the equipment during the service cycle.

-

Download

DownloadQuality and service are the core competencies of Aeros, and all our services are designed to achieve a common goal: to maintain stable production and maintain a high level of productivity of the equipment during the service cycle.

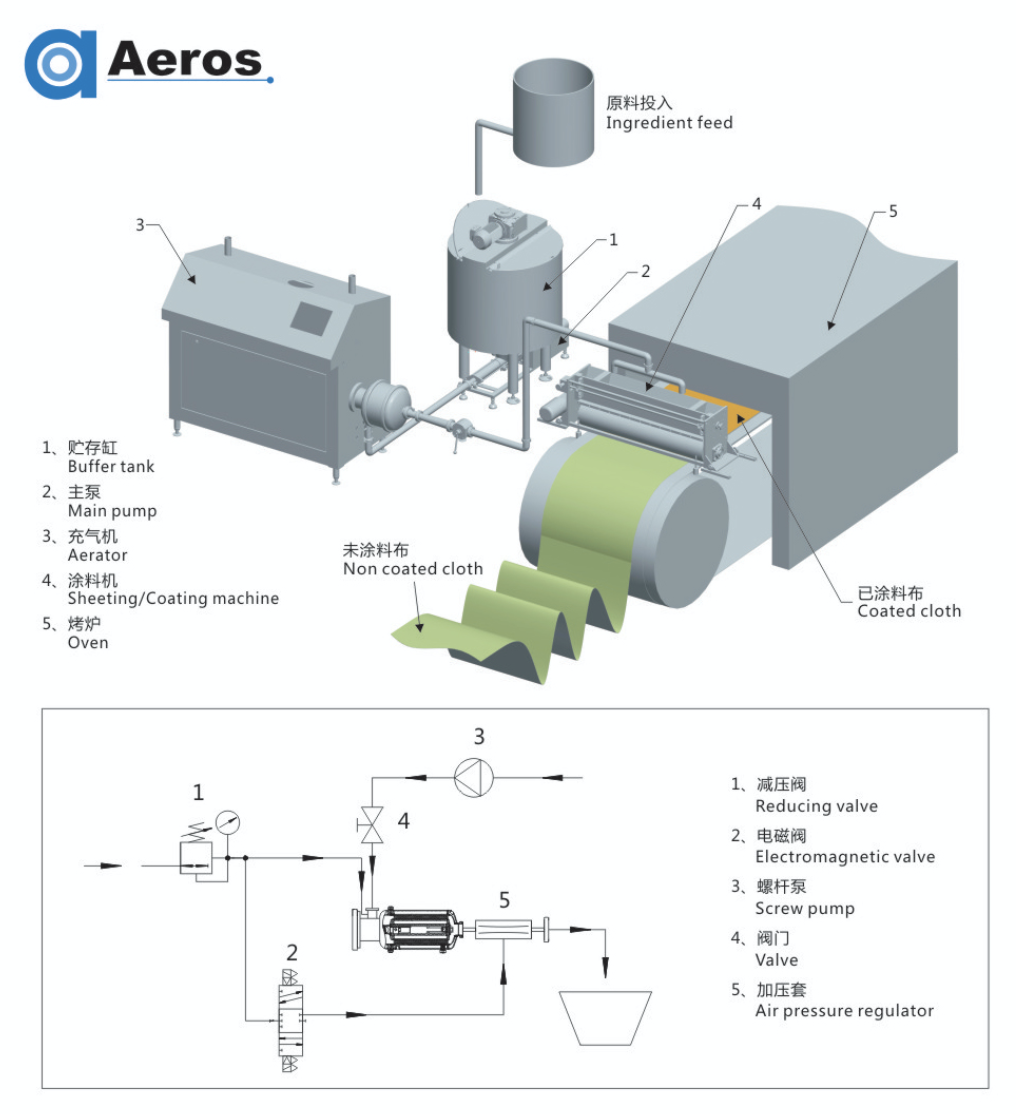

Car seat cover substrate

Car seat cover substrate

The air,synchronises with the main pump, is injected into the mixing head at a rate as set from the touch screen panel. In the mixing head the pins of both the rotor and stator see to it that the air is homogeneously mixed with the ingredient down to the required density and structure.

If necessary, we inject the gel or other chemicals through the front, middle, rear or cover entrance of the mixing head into the foam. It can be set automatically dosing the required amount from the touch screen panel.

From the mixing head the aerated foam is discharged towards the manifold depositing system, mould, trays or steel band oven or discharge to hopper type depositor for further processing.

Foshan Aeros Industrial Equipment Co., Ltd. (Sales Office)

Address: No.6,mingXi Road,Ming Chen Town,Gao ming District, Foshan ,Guangdong Provice,PRC.

Zip Code: 528500

Telephone: 86-181 2352 1651

Fax: 86-757-88933063

Email:oscaryau23@gmail.com

Factory Foshan Aeros Industrial EquipmentCo.,Ltd (Factory)

Address: No.16 Heng Chang Road, He Cheng, Gaoming District, Foshan, Guangdong Province, PRC.

Telephone: 86-757-88933066

Fax: 86-757-88933063

HK Offce:Aeros(international)Co.,Ltd

Address: Rm 5,16/F.,Kwong Kin Trade Centre, 5 Kin Fat Street,Tuen Mum,N,T.,Hong Kong

Telephone: 852 2499 1823

Fax: 852 2499 1822

Whatsapp: 852 9616 0072

Add WeChat to learn more