Unlocking the World of Candy Making Machines: A Comprehensive Guide

2026/01/22

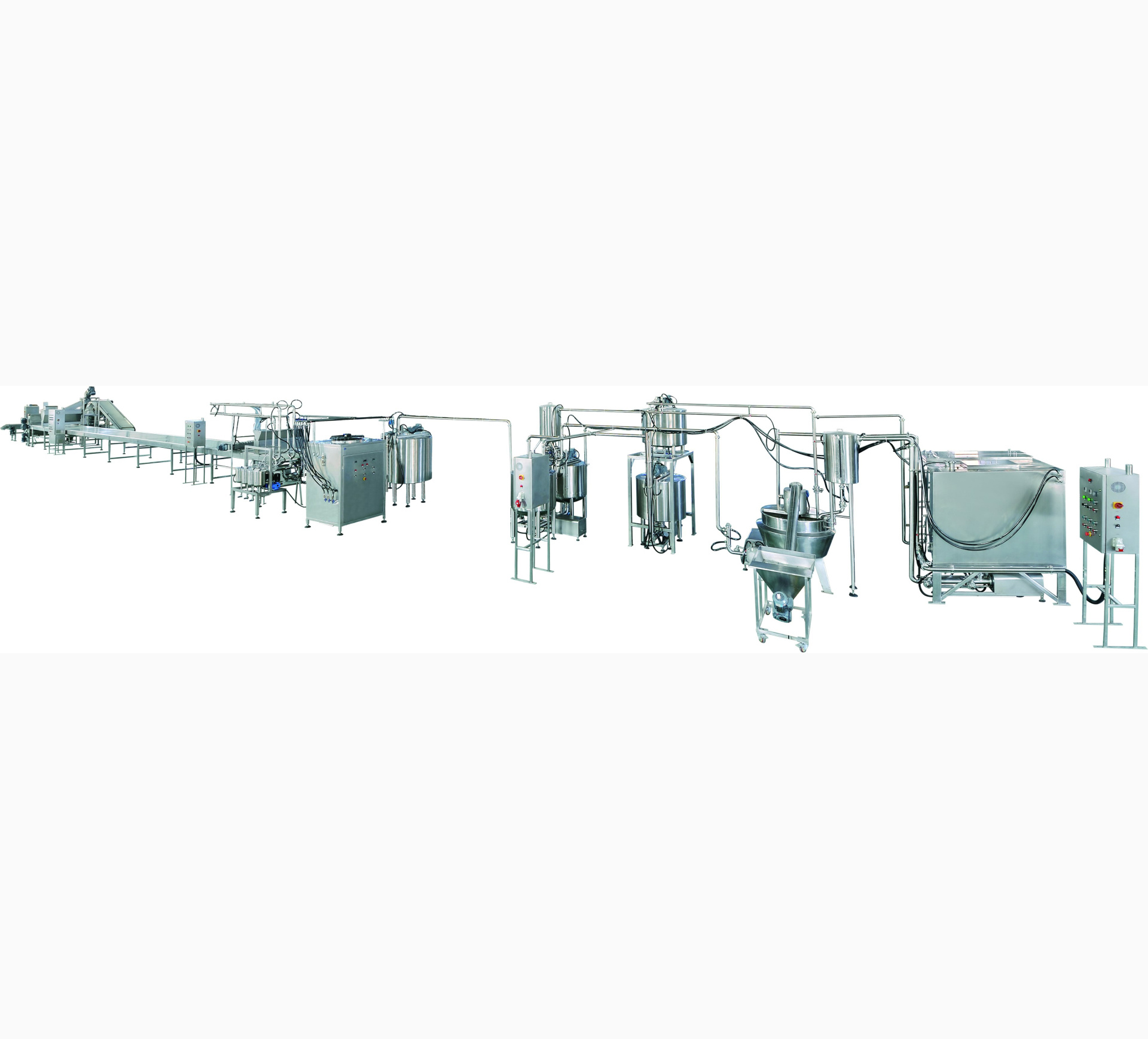

Candy making machines are essential tools in the confectionery industry, designed to streamline the production process of various sweet treats. These machines range from simple devices for small-scale operations to advanced automated systems for large-scale manufacturing. Understanding the functionalities and types of candy making machines can help businesses optimize their production processes and enhance product quality.

One of the primary types of candy making machines is the cooking kettle, which is utilized to cook sugar syrup to achieve the desired consistency and temperature. The precise control offered by modern cooking kettles allows manufacturers to create a wide variety of candies, including hard candies, soft caramels, and gummies. Additionally, these kettles often come with built-in mixing capabilities to ensure homogeneous mixtures, which is crucial for maintaining quality.

Another significant category of candy making machines includes the depositing machines. These machines are responsible for shaping candy into the desired forms, whether it be gummy bears or chocolate-covered treats. By employing advanced technology, depositing machines can produce consistent sizes and shapes, which is critical for branding and consumer satisfaction. Automated depositing machines can significantly increase production speed while minimizing labor costs.

Cooling tunnels are also integral to the candy manufacturing process. After candies are formed, they must be cooled rapidly to solidify their structure and enhance shelf stability. Cooling tunnels provide a controlled environment that ensures uniform cooling, reducing the risk of defects and ensuring that the final product meets quality standards.

Moreover, wrapping machines are vital for the packaging process. Proper packaging not only extends the shelf life of candies but also plays a significant role in marketing. Wrapping machines can efficiently package products in various sizes and formats, ensuring they are presented attractively to consumers while maintaining freshness.

In recent years, the candy making industry has also seen a rise in the integration of technology. Smart candy making machines equipped with IoT capabilities are becoming increasingly common. These machines offer real-time monitoring and control, allowing manufacturers to optimize their production lines and reduce waste. Such advancements can lead to improved efficiency and consistency in candy production.

In conclusion, candy making machines are vital for anyone serious about entering or expanding within the confectionery industry. By selecting the right machines and understanding their functions, manufacturers can improve production efficiency, ensure high-quality products, and enhance their overall business operations. Whether you're looking to create classic favorites or innovate new candy concepts, investing in the appropriate candy making machines is crucial for success.

One of the primary types of candy making machines is the cooking kettle, which is utilized to cook sugar syrup to achieve the desired consistency and temperature. The precise control offered by modern cooking kettles allows manufacturers to create a wide variety of candies, including hard candies, soft caramels, and gummies. Additionally, these kettles often come with built-in mixing capabilities to ensure homogeneous mixtures, which is crucial for maintaining quality.

Another significant category of candy making machines includes the depositing machines. These machines are responsible for shaping candy into the desired forms, whether it be gummy bears or chocolate-covered treats. By employing advanced technology, depositing machines can produce consistent sizes and shapes, which is critical for branding and consumer satisfaction. Automated depositing machines can significantly increase production speed while minimizing labor costs.

Cooling tunnels are also integral to the candy manufacturing process. After candies are formed, they must be cooled rapidly to solidify their structure and enhance shelf stability. Cooling tunnels provide a controlled environment that ensures uniform cooling, reducing the risk of defects and ensuring that the final product meets quality standards.

Moreover, wrapping machines are vital for the packaging process. Proper packaging not only extends the shelf life of candies but also plays a significant role in marketing. Wrapping machines can efficiently package products in various sizes and formats, ensuring they are presented attractively to consumers while maintaining freshness.

In recent years, the candy making industry has also seen a rise in the integration of technology. Smart candy making machines equipped with IoT capabilities are becoming increasingly common. These machines offer real-time monitoring and control, allowing manufacturers to optimize their production lines and reduce waste. Such advancements can lead to improved efficiency and consistency in candy production.

In conclusion, candy making machines are vital for anyone serious about entering or expanding within the confectionery industry. By selecting the right machines and understanding their functions, manufacturers can improve production efficiency, ensure high-quality products, and enhance their overall business operations. Whether you're looking to create classic favorites or innovate new candy concepts, investing in the appropriate candy making machines is crucial for success.

Candy making machines