Innovations in Confectionery Machinery: What's New in 2023?

2026/01/19

Innovations in Confectionery Machinery: What's New in 2023?

Table of Contents

- 1. Introduction to Confectionery Machinery Innovations

- 2. Importance of Modernizing Confectionery Machinery

- 3. Latest Technologies in Confectionery Machinery

- 3.1. Automation in Confectionery Production

- 3.2. Role of AI in Manufacturing

- 3.3. Data Analytics for Enhanced Production Efficiency

- 4. Sustainability Trends in Confectionery Machinery

- 5. Innovations Enhancing Product Quality

- 6. Meeting Evolving Consumer Demands

- 7. The Future of Confectionery Machinery

- 8. Conclusion

1. Introduction to Confectionery Machinery Innovations

The confectionery industry has always been a dynamic field, characterized by rapid changes and technological advancements. In 2023, we observe an exciting array of innovations in confectionery machinery that are reshaping production processes, enhancing efficiency, and improving product quality. These advancements not only meet the increasing consumer demand for diverse candy and snack options but also align with sustainability goals that are now more critical than ever.

As we explore **the latest innovations**, it becomes clear how these developments are setting new standards in the food and beverage processing machinery sector.

2. Importance of Modernizing Confectionery Machinery

Modernizing confectionery machinery is pivotal for several reasons. First and foremost, it allows manufacturers to **increase production efficiencies**. With the rising costs of labor and materials, leveraging new technologies can lead to significant cost savings and improved profit margins. Additionally, modern machinery often incorporates advanced features that support higher levels of **precision and consistency**, which are crucial in maintaining product quality.

Furthermore, updated machinery can help businesses comply with stricter food safety regulations and standards. In a competitive marketplace, staying ahead of the curve not only ensures compliance but also enhances brand reputation and consumer trust.

3. Latest Technologies in Confectionery Machinery

The technological landscape of confectionery machinery continuously evolves, bringing forth innovations that transform production lines. Here are some of the most significant advancements in 2023:

3.1. Automation in Confectionery Production

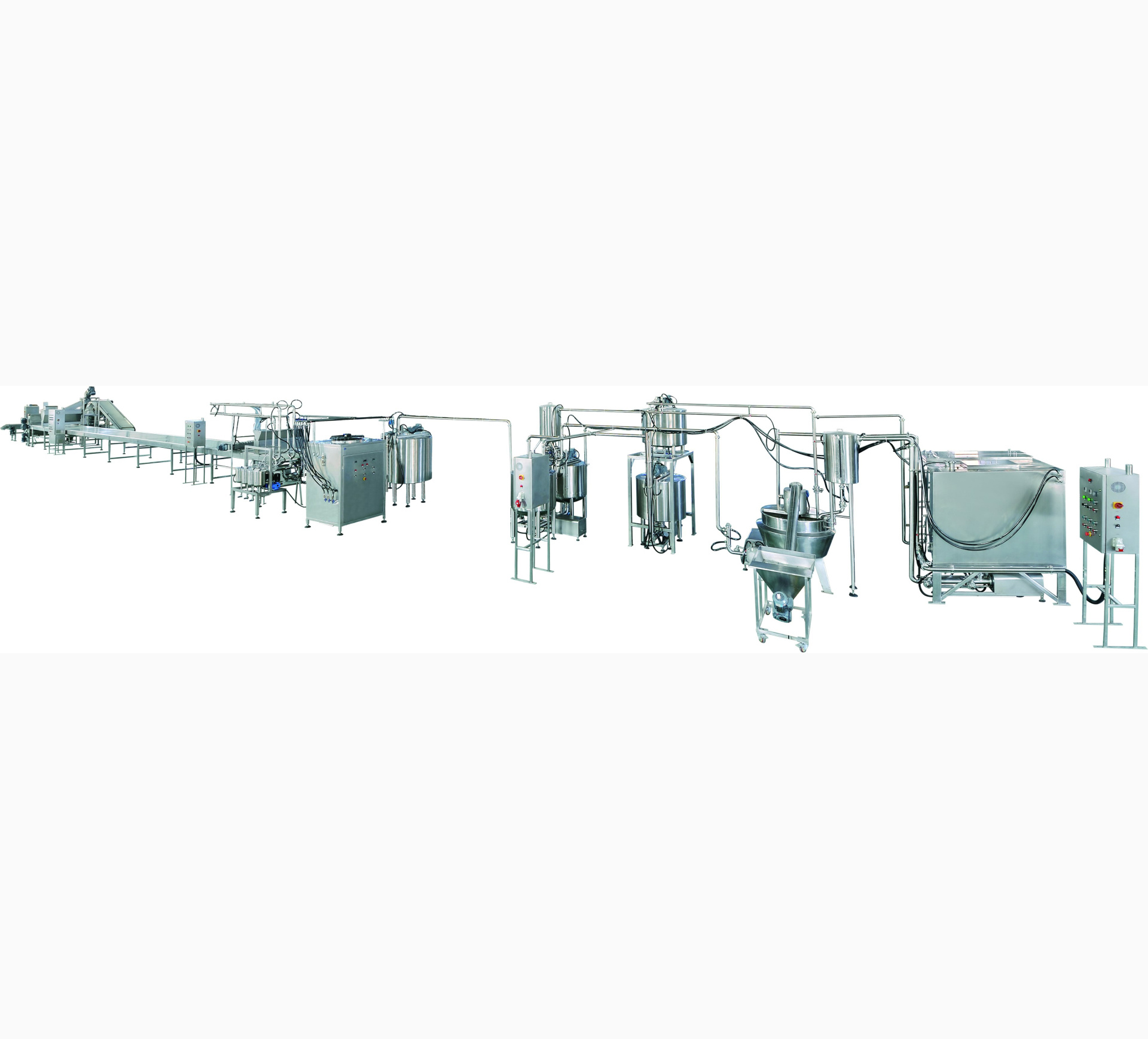

Automation remains at the forefront of innovations in confectionery machinery. The introduction of **fully automated production lines** has streamlined processes, reducing the need for manual labor and minimizing human error. Automated systems can adjust parameters in real time, ensuring optimal conditions for various stages of production, from mixing ingredients to packaging.

With automation, manufacturers can achieve higher production rates, allowing them to respond swiftly to market demands. Moreover, automated setups are more flexible, accommodating different product sizes and types without extensive downtime for reconfiguration.

3.2. Role of AI in Manufacturing

Artificial Intelligence (AI) is playing a transformative role in confectionery machinery. In 2023, manufacturers are leveraging AI-driven solutions for predictive maintenance, quality control, and inventory management. By analyzing data collected from machinery, AI systems can anticipate equipment failures, leading to reduced downtime and maintenance costs.

AI technology also supports enhanced product quality. Machine learning algorithms analyze production data to identify anomalies and deviations from quality standards, allowing manufacturers to make real-time adjustments. This capability ensures that the final products meet stringent quality benchmarks consistently.

3.3. Data Analytics for Enhanced Production Efficiency

Data analytics is another critical component driving innovation in confectionery machinery. By harnessing big data, manufacturers can gain valuable insights into their production processes. These insights facilitate better decision-making, leading to optimized operations and reduced waste.

Advanced data analytics tools can track production metrics such as yield rates, processing times, and energy consumption. This information empowers manufacturers to identify bottlenecks, improve workflows, and enhance overall efficiency. Additionally, predictive analytics can help forecast demand trends, enabling better inventory management and resource allocation.

4. Sustainability Trends in Confectionery Machinery

Sustainability has become a crucial consideration in the design and operation of confectionery machinery. As the industry faces increasing pressure to reduce its environmental impact, manufacturers are integrating sustainable practices into their operations.

In 2023, we see a notable shift toward energy-efficient machinery, which lowers energy consumption during production. Furthermore, many manufacturers are exploring **biodegradable materials** for packaging, reducing the reliance on plastics and minimizing waste.

Additionally, innovations such as **heat recovery systems** are being employed to recycle energy within the production process, further enhancing sustainability efforts. By prioritizing eco-friendly practices, confectionery manufacturers not only contribute to environmental conservation but also appeal to eco-conscious consumers.

5. Innovations Enhancing Product Quality

Enhanced product quality remains a top priority across the confectionery industry. In 2023, innovations in machinery are contributing significantly to achieving this goal.

One notable advancement is the development of **precision dosing systems** that ensure the exact quantity of ingredients is used in each batch. This precision is vital in maintaining flavor consistency and meeting consumer expectations.

Moreover, machinery equipped with advanced cooling and heating technologies helps achieve optimal texture and shelf life for confectionery products. This ensures that products maintain their quality from production through distribution to the retail shelf, reinforcing brand loyalty among consumers.

6. Meeting Evolving Consumer Demands

The confectionery market is characterized by rapidly changing consumer preferences. In 2023, consumers are increasingly seeking healthier options, unique flavor profiles, and specialty diets such as vegan or gluten-free.

To address these demands, manufacturers must adapt their machinery and production processes accordingly. Innovations that allow for **customization** in confectionery production are gaining popularity. For example, machinery can now accommodate smaller batch sizes, enabling the production of limited-edition flavors or specialty items without extensive reconfiguration.

Furthermore, the rise of online shopping and direct-to-consumer sales channels is prompting confectionery manufacturers to rethink their packaging and product presentation. Innovations that improve packaging aesthetics and functionality are essential for attracting consumers in a crowded marketplace.

7. The Future of Confectionery Machinery

As we look ahead, the future of confectionery machinery appears promising, driven by continuous innovation and technological advancements. We anticipate further integration of smart technologies, including IoT (Internet of Things) devices that enable real-time monitoring and control of production lines.

Moreover, the focus on sustainability will likely intensify, with more manufacturers prioritizing eco-friendly materials and processes. Innovations in plant-based alternatives and sustainable sourcing of ingredients will shape the future landscape of confectionery manufacturing.

Additionally, advancements in robotics will continue to enhance automation, allowing for even greater efficiency and flexibility in production processes.

8. Conclusion

In conclusion, the confectionery machinery landscape in 2023 is marked by significant innovations that enhance production efficiency, improve product quality, and align with sustainability goals. As manufacturers embrace automation, AI, and data analytics, they position themselves to meet evolving consumer demands effectively.

The commitment to modernizing machinery not only streamlines operations but also ensures compliance with industry standards and fosters consumer trust. As we move forward, the continued integration of technology and sustainable practices will define the future of the confectionery industry. Embracing these innovations is not just beneficial; it is essential for thriving in an increasingly competitive marketplace.

Frequently Asked Questions (FAQs)

1. What are the latest trends in confectionery machinery for 2023?

The latest trends include automation, AI integration, data analytics, and sustainable practices, all aimed at enhancing efficiency and product quality.

2. How is automation impacting the confectionery industry?

Automation is streamlining production processes, reducing labor costs, and minimizing human error, which ultimately leads to increased production efficiency.

3. What role does AI play in confectionery manufacturing?

AI enhances predictive maintenance, quality control, and inventory management, allowing manufacturers to optimize operations and ensure product consistency.

4. Why is sustainability important in confectionery machinery?

Sustainability is crucial for reducing environmental impact, meeting regulatory standards, and appealing to eco-conscious consumers.

5. How can manufacturers meet changing consumer demands?

Manufacturers can adapt by offering customizable products, utilizing innovative packaging solutions, and incorporating healthier ingredient options to align with consumer preferences.

Confectionery machinery