Transforming Your Production: The Secrets of Quality Cream Aeration Machines

2025/07/18

Transforming Your Production: The Secrets of Quality Cream Aeration Machines

Table of Contents

- 1. Introduction to Cream Aeration Machines

- 2. The Importance of Cream Aeration in Food Processing

- 3. How Cream Aeration Machines Work

- 4. Benefits of Quality Cream Aeration Machines

- 5. How to Choose the Right Cream Aeration Machine

- 6. Maintenance Tips for Optimal Performance

- 7. Industry Trends in Cream Aeration Technology

- 8. Conclusion

- 9. FAQs

1. Introduction to Cream Aeration Machines

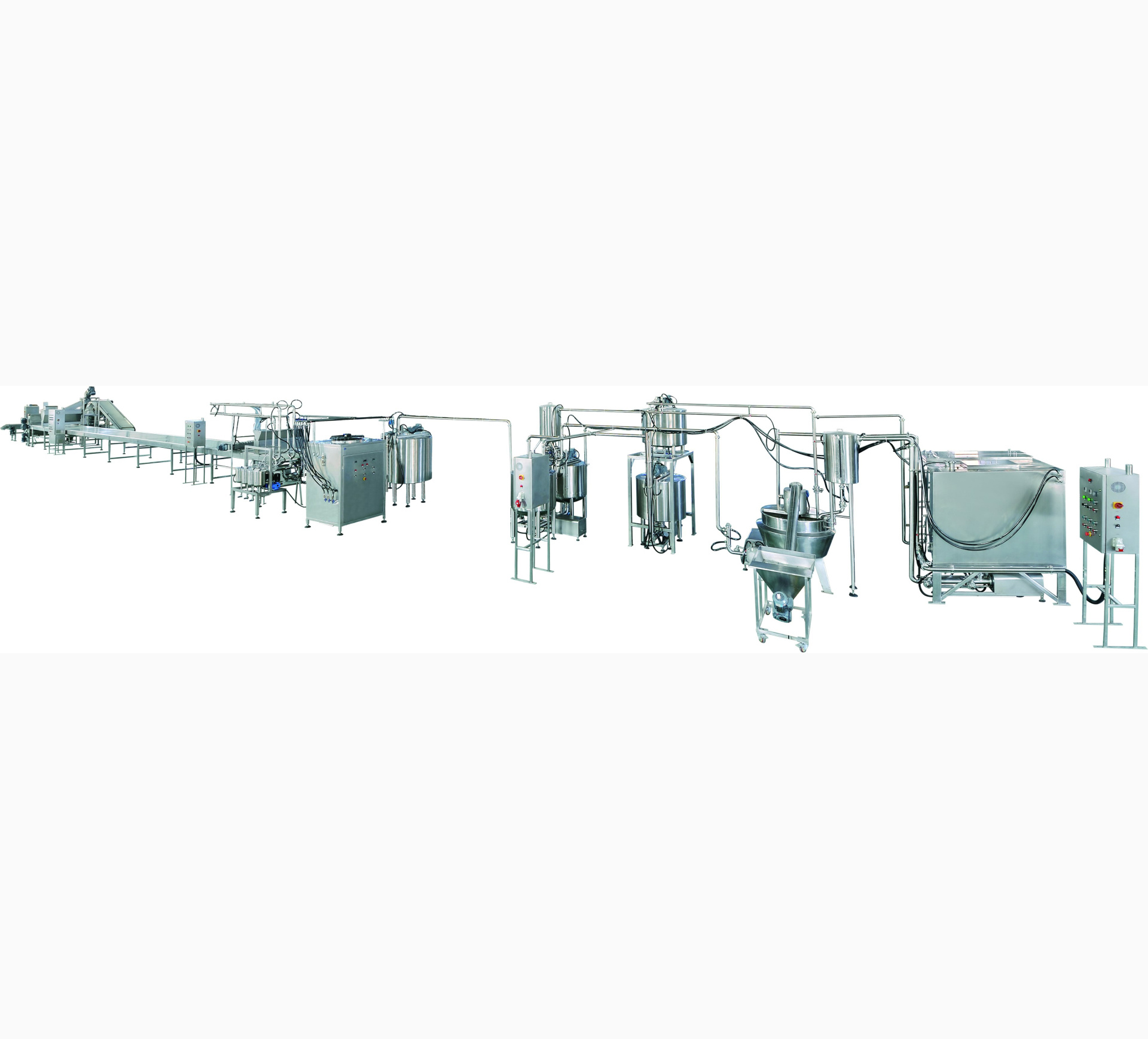

In the competitive landscape of food and beverage manufacturing, efficiency, product quality, and innovation play pivotal roles in business success. **Cream aeration machines** have emerged as essential equipment for manufacturers aiming to enhance the texture and stability of their cream-based products. These machines are designed to incorporate air into the cream, creating the light, fluffy consistency that consumers expect in whipped toppings, desserts, and other dairy products.

Cream aeration not only elevates product quality but also contributes to the overall efficiency of production processes. Understanding the mechanics and advantages of these machines can help businesses make informed decisions that lead to improved output and customer satisfaction.

2. The Importance of Cream Aeration in Food Processing

Cream aeration is a critical process in the production of various food items. The principal reasons for incorporating aeration in cream include:

Enhancing Texture and Mouthfeel

A well-aerated cream has a smooth, creamy texture that enhances the sensory experience. This quality is essential for products like mousses, whipped creams, and frostings, where texture plays a crucial role in consumer preference.

Increasing Volume and Yield

Aeration increases the volume of cream, allowing manufacturers to produce more product with the same amount of raw material. This not only boosts profitability but also optimizes ingredient usage, reducing waste in production cycles.

Improving Stability and Shelf Life

Proper aeration techniques help maintain the stability of cream products, reducing the risk of separation and spoilage. This stability ensures that products remain appealing to consumers for longer periods, extending shelf life and enhancing marketability.

3. How Cream Aeration Machines Work

Understanding the functionality of cream aeration machines is essential for manufacturers looking to implement or upgrade their equipment.

Basic Mechanics of Aeration

At its core, a cream aeration machine works by introducing air into the cream. The process typically involves the following steps:

1. **Preparation**: Cream is prepared by ensuring it reaches the appropriate temperature and consistency.

2. **Aeration Process**: The cream is pumped into the aeration chamber, where air is injected under controlled conditions. Various designs may utilize different mechanisms, such as high-speed mixers or centrifugal force, to achieve optimal aeration.

3. **Texture Adjustment**: The machine allows operators to adjust variables like air incorporation rate and mixing speed, enabling precise control over the final texture and volume of the cream.

4. **Quality Control**: Continuous monitoring during the aeration process ensures that the desired quality is consistently achieved.

Types of Cream Aeration Machines

Different types of cream aeration machines are available, including:

- **Batch Aerators**: Suitable for smaller quantities, these machines are ideal for artisanal producers.

- **Continuous Aerators**: Designed for high-volume production, these machines provide a steady flow of aerated cream for large-scale operations.

4. Benefits of Quality Cream Aeration Machines

Investing in quality cream aeration machines offers numerous benefits that can significantly impact production efficacy and product quality.

Enhanced Product Quality

High-quality aeration results in cream that meets or exceeds consumer expectations. A light and airy texture is not only desirable but also crucial for brand reputation.

Improved Operational Efficiency

Modern cream aeration machines are designed for efficiency. They minimize energy consumption and reduce processing time, allowing for higher production rates and lower operational costs.

Versatility in Production

Many cream aeration machines can be used for various applications, from whipping cream for desserts to incorporating air into sauces and dips. This versatility makes them valuable assets in diverse production environments.

Reduced Labor Costs

Automation features in contemporary cream aeration machines streamline operations, reducing the need for extensive manual labor. This shift not only cuts costs but also allows workers to focus on more complex tasks.

5. How to Choose the Right Cream Aeration Machine

Selecting the appropriate cream aeration machine requires careful consideration of several factors to ensure that it meets your production needs effectively.

Production Volume Requirements

Understanding your production capacity is crucial. Evaluate whether your operations require a batch or continuous aeration system based on your output needs.

Product Specifications

Different products may require different aeration techniques. Consider the specific requirements of the cream you’re processing, such as fat content and desired texture.

Energy Efficiency

Opt for machines that boast energy-efficient designs, as this can lead to significant cost savings over time. Look for models with lower energy consumption without compromising on performance.

Maintenance and Support

Choose manufacturers that provide excellent customer support and offer comprehensive maintenance plans. A reliable service provider can help mitigate downtime and extend the machine's lifespan.

6. Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your cream aeration machine, regular maintenance is essential. Here are some tips to keep your equipment in peak condition:

Regular Cleaning

After each use, clean the aeration chamber and other components to prevent residue buildup. Stagnant cream can lead to spoilage and affect future batches.

Monitor Performance

Keep an eye on machine performance indicators. If you notice a drop in efficiency or changes in product quality, it may be time to consult with a technician.

Scheduled Inspections

Implement a routine inspection schedule to check for wear and tear on moving parts. Regular checks can help identify potential issues before they lead to costly repairs.

Follow Manufacturer Guidelines

Always adhere to the maintenance recommendations provided by the manufacturer. These guidelines are designed to optimize performance and extend the machine's operational life.

7. Industry Trends in Cream Aeration Technology

The food and beverage processing industry is continually evolving, and so are the technologies that support it. Here are some current trends in cream aeration technology:

Integration of Smart Technology

Smart technology is becoming increasingly common in food processing equipment. Aeration machines now come equipped with IoT capabilities, allowing for real-time monitoring and adjustments that enhance efficiency.

Sustainability Initiatives

With growing awareness of sustainability, manufacturers are seeking eco-friendly solutions. Energy-efficient aeration machines and biodegradable packaging options are gaining traction.

Customization and Flexibility

There is a rising demand for customizable production solutions. Cream aeration machines that offer adjustable settings for various products are becoming more popular among manufacturers looking to diversify their offerings.

8. Conclusion

Quality cream aeration machines are indispensable tools in the food and beverage processing industry. They not only enhance the texture and stability of cream but also improve overall operational efficiency. As the market continues to evolve, investing in the right aeration technology can lead to significant advantages, ensuring that your products meet consumer expectations and stand out in a competitive landscape.

By understanding the intricacies of cream aeration machines and their benefits, manufacturers can make informed decisions that will transform their production processes. With the right equipment in place, businesses can not only elevate their product quality but also drive profitability and growth.

9. FAQs

What is a cream aeration machine?

A cream aeration machine is equipment designed to introduce air into cream, enhancing its texture and stability for various food applications.

Why is aeration important in food processing?

Aeration improves texture, increases volume, and enhances the stability of cream products, all of which are vital for consumer satisfaction and product quality.

How do I choose the right cream aeration machine for my business?

Consider factors such as production volume, product specifications, energy efficiency, and maintenance support when selecting a cream aeration machine.

What maintenance is required for cream aeration machines?

Regular cleaning, performance monitoring, scheduled inspections, and adherence to manufacturer guidelines are essential for maintaining your cream aeration machine.

What are the latest trends in cream aeration technology?

Current trends include smart technology integration, sustainability initiatives, and a focus on customization and flexibility in production solutions.

By following these insights and recommendations, businesses can harness the full potential of cream aeration machines, transforming their production processes and delivering high-quality products to consumers.

quality Cream aeration machine